Assembly type cavity floor with ribbed beams

A cavity floor and prefabricated technology, which is applied to the preparation of floors, formwork/formwork/work frames, and building components on site, and can solve problems such as structural cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described below in conjunction with the accompanying drawings.

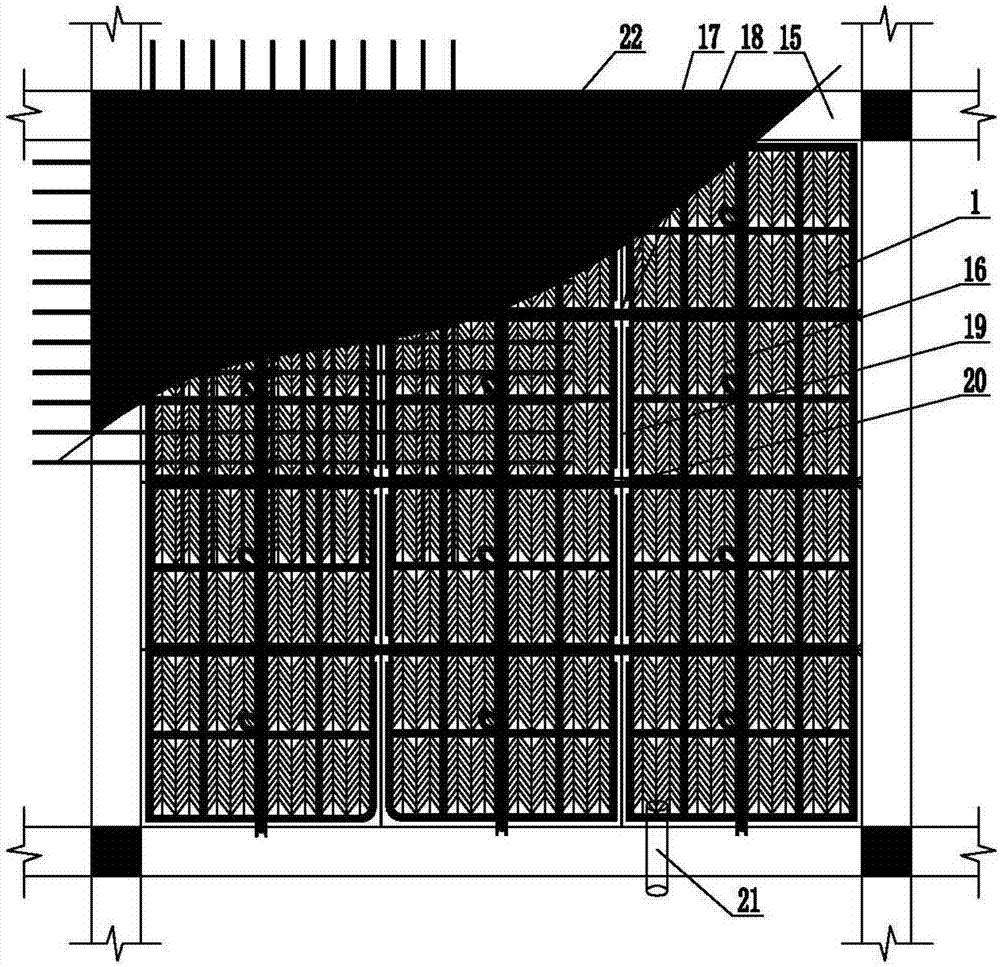

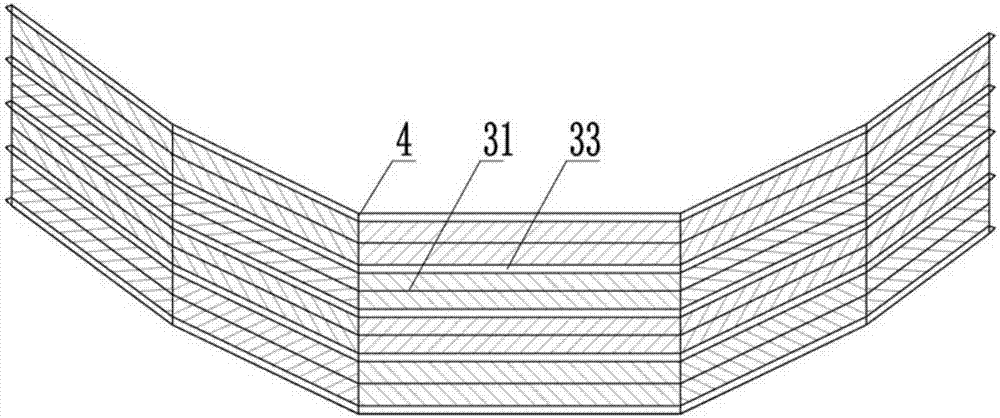

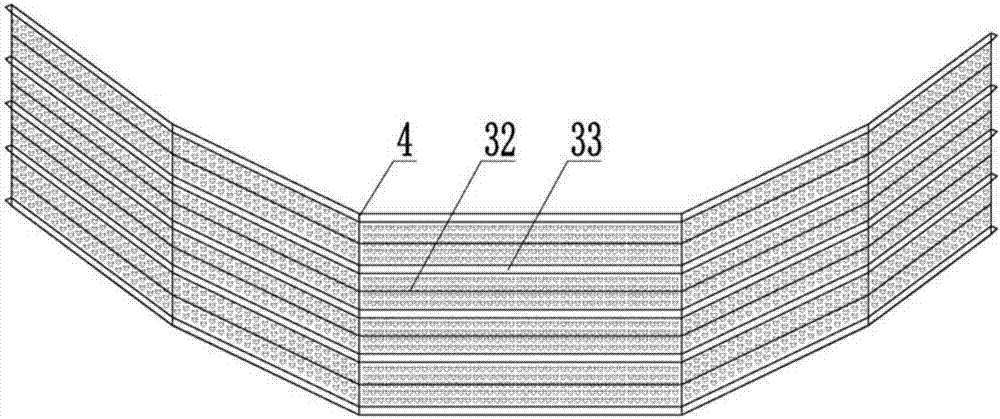

[0030] figure 1 It is an embodiment of a prefabricated cavity floor with ribbed beams of the present invention. When the present invention is implemented, the ribbed steel mesh body 1 prepared from the factory is transported to the production site; Or produce foamed cement blocks of the required specifications at the construction site; place the foamed cement block at the fixed-length mold mark of the ribbed steel mesh, wrap the foamed cement block with the ribbed steel mesh along the fixed-scale mold mark, and place the ribbed steel mesh The two ends of the stencil are assembled and overlapped and welded, and assembled into a stencil body of the required specification; the assembled cavity plate member 16 is fabricated; The lower edge of the side rib beam of a cavity plate member is exposed to the prefabricated concrete slab 17, and the ribbed beam steel bar 19 is bound in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com