Energy adjustment system

An energy adjustment and displacement technology, applied in fluid transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as low efficiency, occupying effective space, increasing weight, etc., achieving simple structure, good load response, and convenience. Kinetic energy regeneration and the effect of the drivetrain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

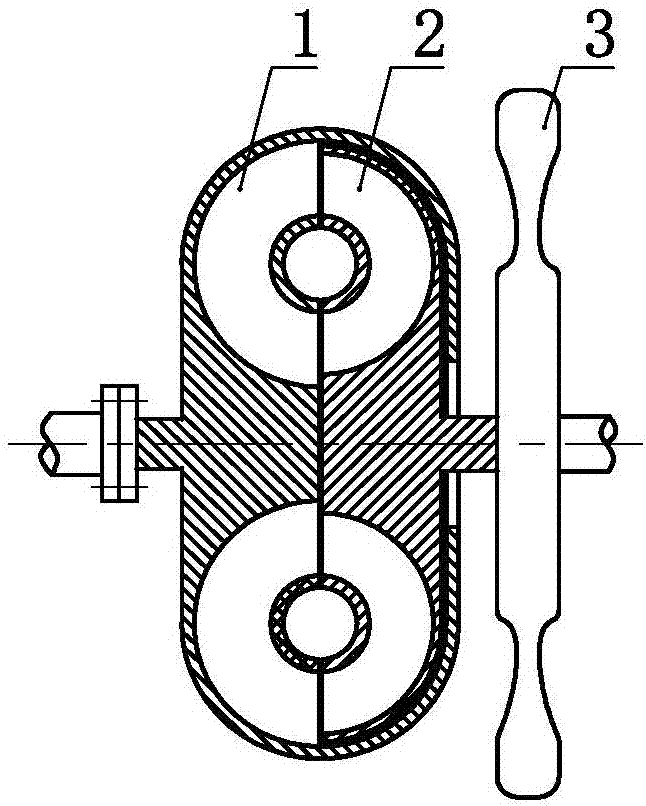

[0029] An energy regulation system such as Figure 1.1 and 1.2 As shown, it includes a pump wheel 1 and a turbine 2, the pump wheel 1 and the turbine 2 are connected in series, the turbine 2 is mechanically connected to the rotating inertia body 3, and the working medium of the pump wheel 1 and the turbine 2 Either as a gas or as a gas-liquid two-phase mixture.

Embodiment 2

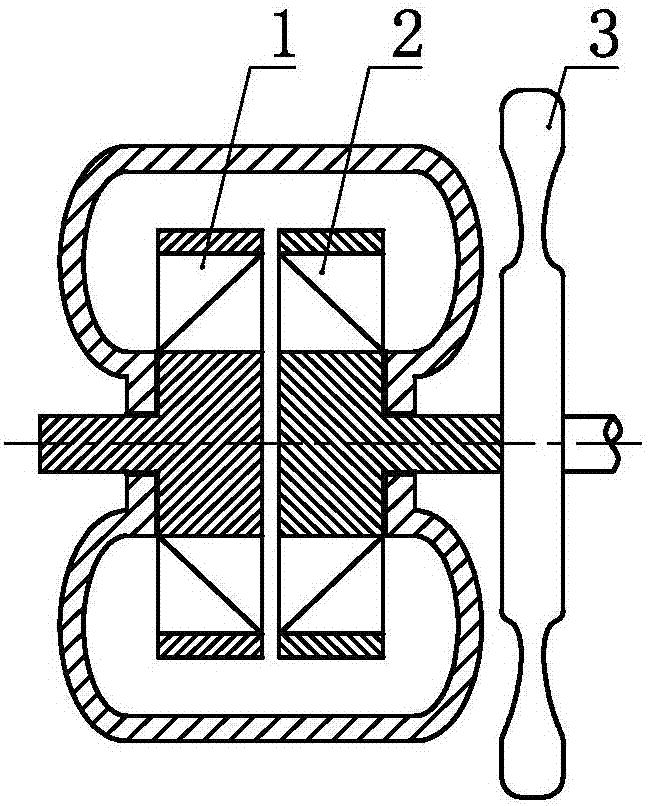

[0031] An energy regulation system such as Figure 2.1 and 2.2 As shown, the pump wheel 1 and the turbine wheel 2 are included, the pump wheel 1 and the turbine wheel 2 are connected in series, the turbine wheel 2 is increased in weight, and the working medium of the pump wheel 1 and the turbine wheel 2 is set as gas or It is a gas-liquid two-phase mixture.

Embodiment 3

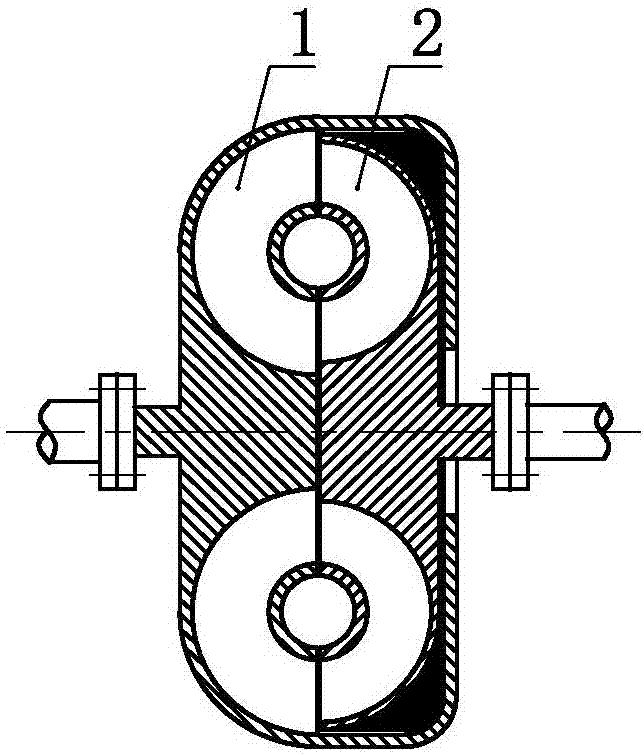

[0033] An energy regulation system such as Figure 3.1 and 3.2 As shown, the pump wheel 1 and the turbine wheel 2 are included, and the pump wheel 1 and the turbine wheel 2 are connected in series. 1 and the working medium of the turbine 2 are set as gas or as a gas-liquid two-phase mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com