Vertical high-temperature environmental protecting briquette drying oven

A technology for drying furnace and briquette, applied in drying, drying machine, drying solid materials and other directions, can solve the problems of material movement accumulation, large amount of waste heat recovery, long drying time, etc. The effect of reducing the amount of briquettes and briquettes and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

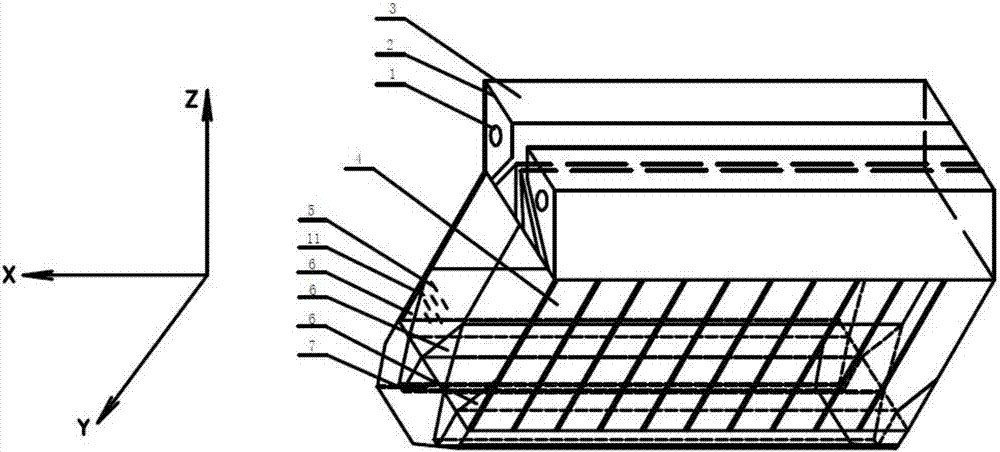

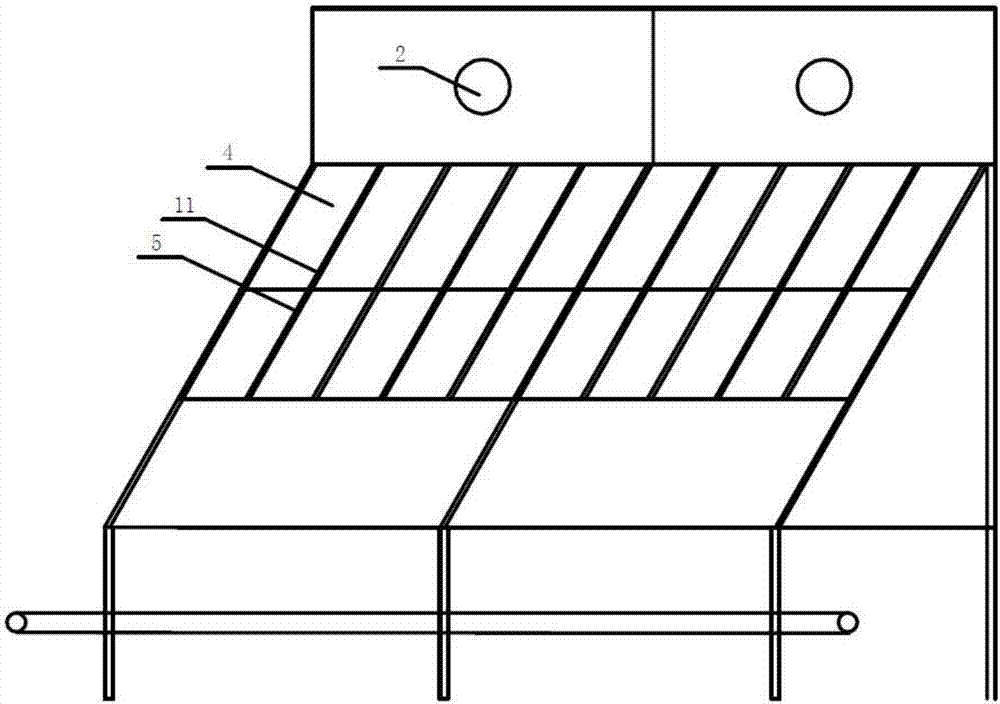

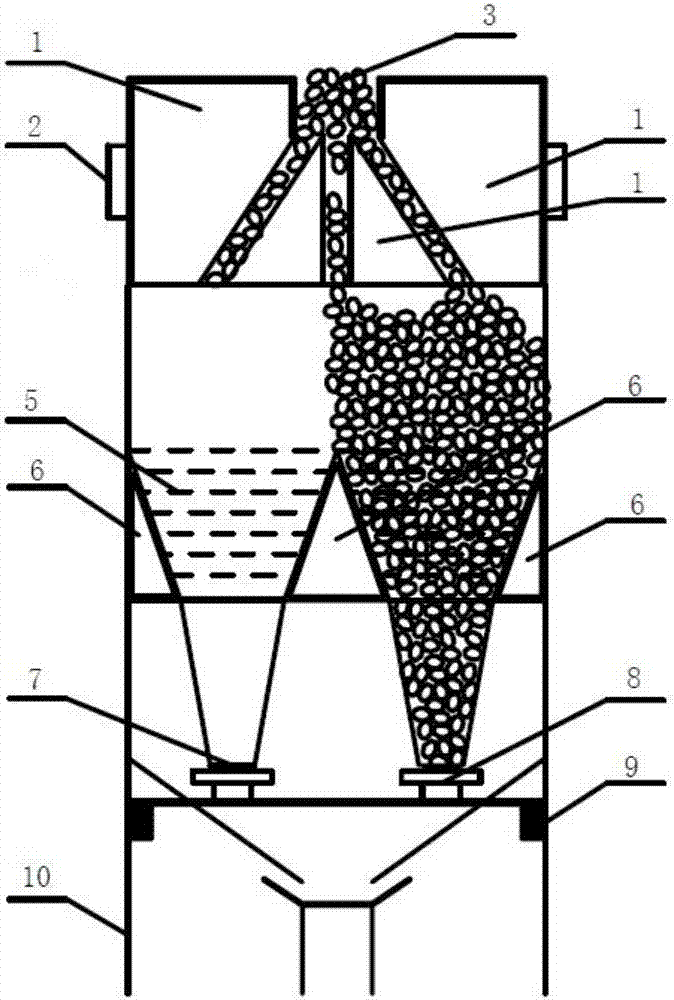

[0057] In the following examples, the briquette drying furnace of the present invention is used as follows: a height of 1.5 meters, three feed ports, a 45° oblique angle between the box body and the horizontal plane, and the narrowing position of the box body side plate is raised upwards To the 1 / 3 of the box body 4, the closing angle of the side plate of the box body and the XZ plane form an angle of 19°, while the opening of the feeding port forms an angle of 10° with the XZ plane.

[0058] In contrast, the use height is 3 meters, there is only one feeding port, the box body is perpendicular to the horizontal plane, the narrowing position of the side plate box body is located at 1 / 2 of the box body 4, and the closing angle is 19 degrees to the XZ plane , and the commercially available briquette drying furnace with an angle of 30 degrees between the opening of the feeding port and the XZ plane.

[0059] Add the briquettes to be dried into the briquette drying furnace of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com