Full automatic thickness gauge for pipe network monitoring system

A monitoring system and fully automatic technology, applied in instruments, measuring devices, using ultrasonic/sonic/infrasonic waves, etc., can solve problems such as unfavorable computer data processing and analysis, large randomness of detection parts, and large workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

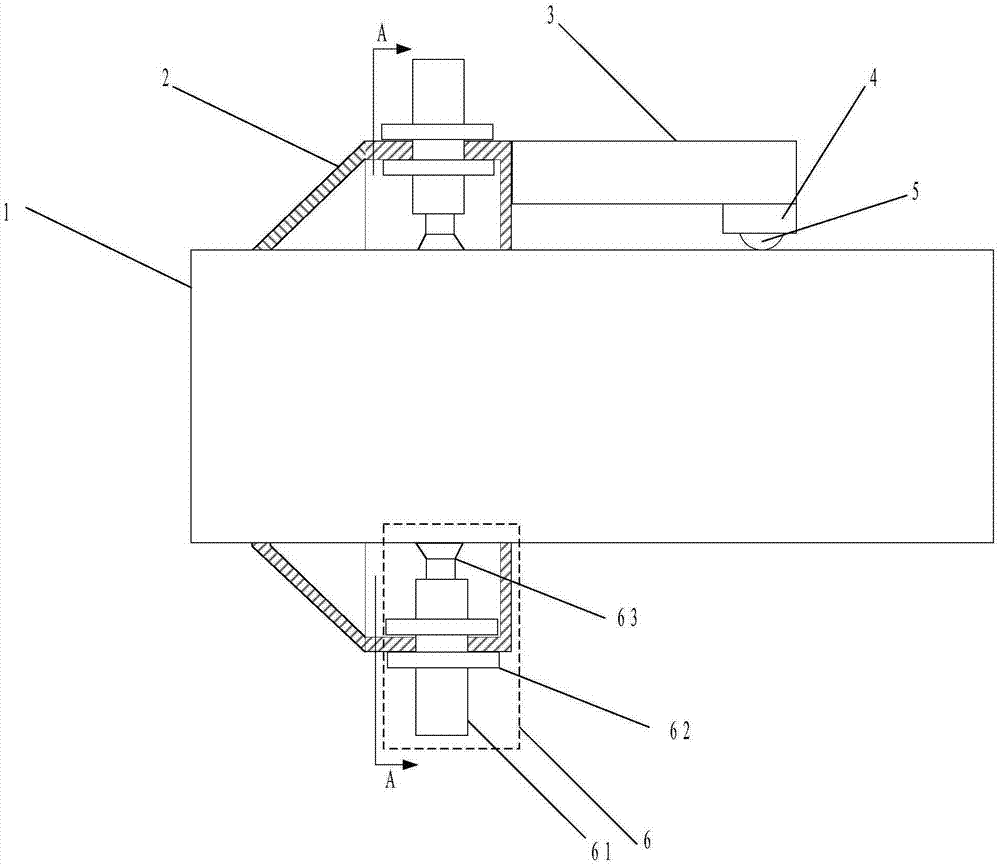

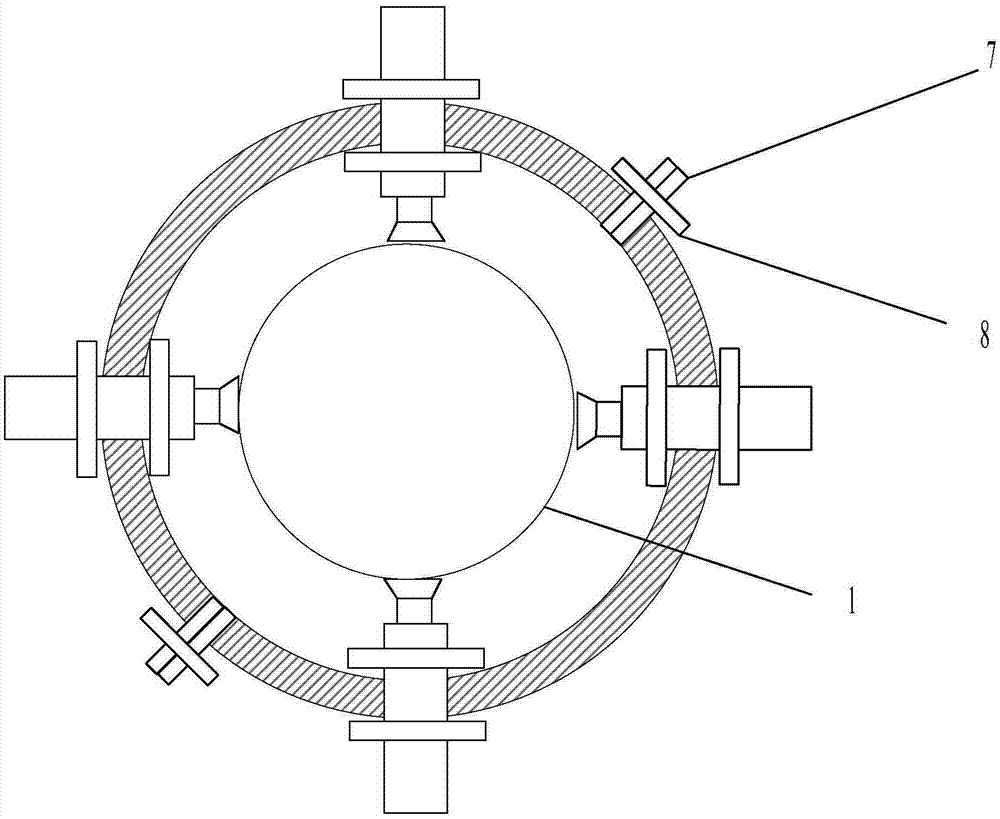

[0015] Such as Figure 1-3 As shown, a fully automatic thickness gauge for a pipe network monitoring system includes: a hollow shell 2 with a conical head. The conical head is used to remove debris from the outside of the pipe to be measured. 2 It is made up of two identical parts connected by flange 7 and bolt 8;

[0016] Several ultrasonic wall thickness measuring devices 6 are evenly distributed on the shell 2 and arranged radially inward; under normal circumstances, one can be set in the horizontal and vertical directions of the shell 2, a total of 4 ultrasonic wall thickness measurements 器6.

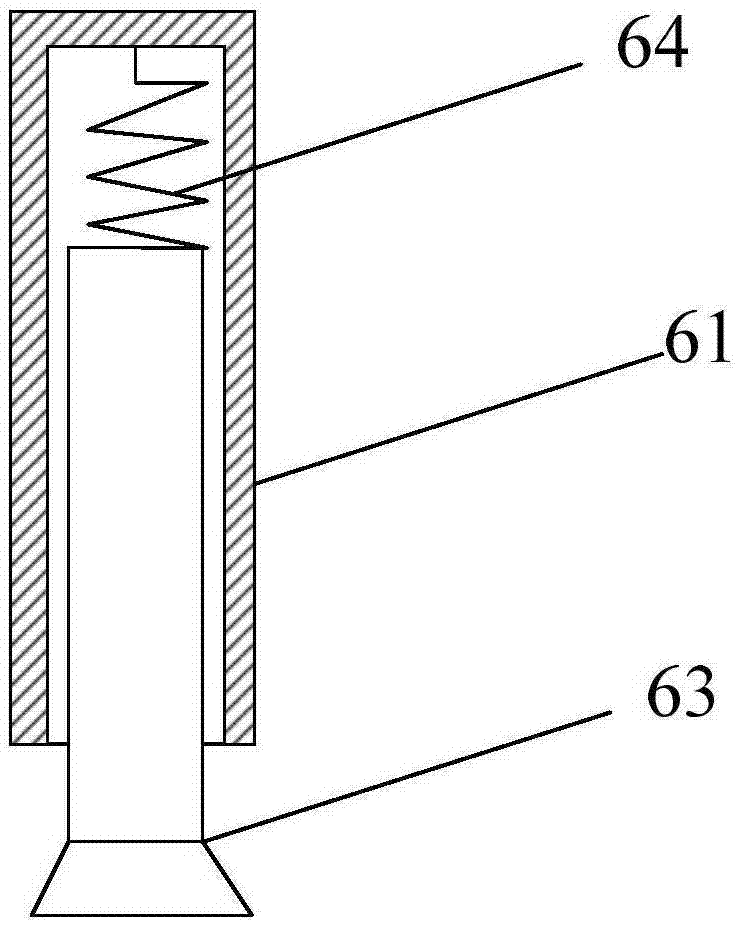

[0017] The ultrasonic wall thickness measuring instrument 6 can move in the radial direction, and includes a measuring body 61 with threads on the surface, and nuts 62 that are used to fix the measuring body 61 and are respectively arranged inside and outside the housing 2, and are arranged inside the measuring body 61 The vertical telescopic spring 64 and the probe 63 fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com