Drop seepage characteristic monitoring method and device for cross-scale movement slits

A monitoring device and cross-scale technology, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of inapplicability, inability to change the shape and gap of slits according to needs, and inconvenient replacement of materials, etc. problem, to achieve the effect of precise control of the slit spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

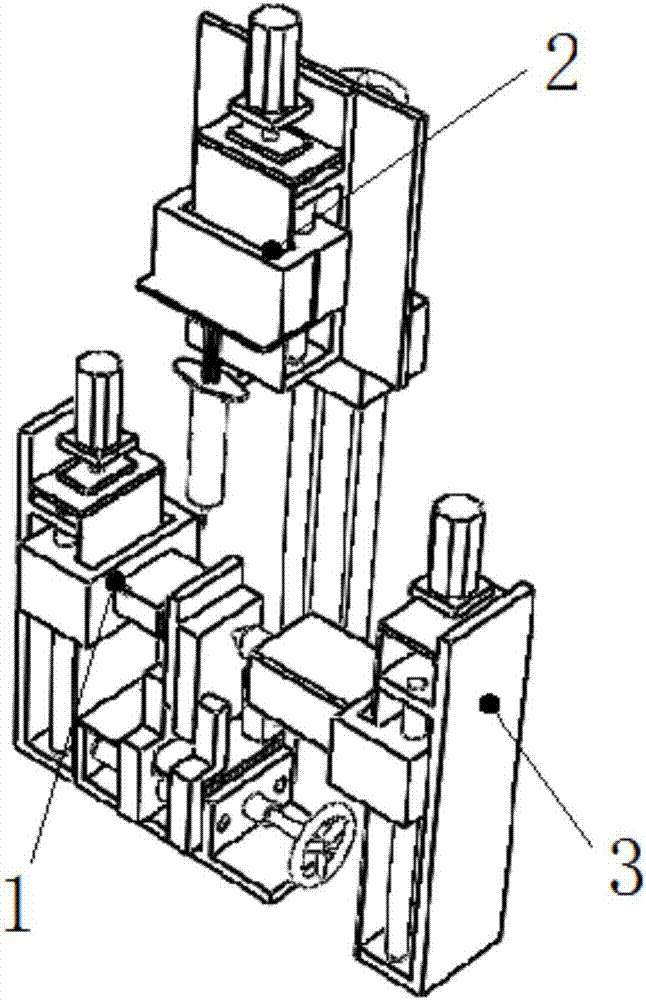

[0024] Such as figure 1 As shown, the droplet seepage characteristic monitoring device for cross-scale moving slits includes a slit shape adjustment module 1 , a micro-feeding module 2 and a detection and monitoring module 3 .

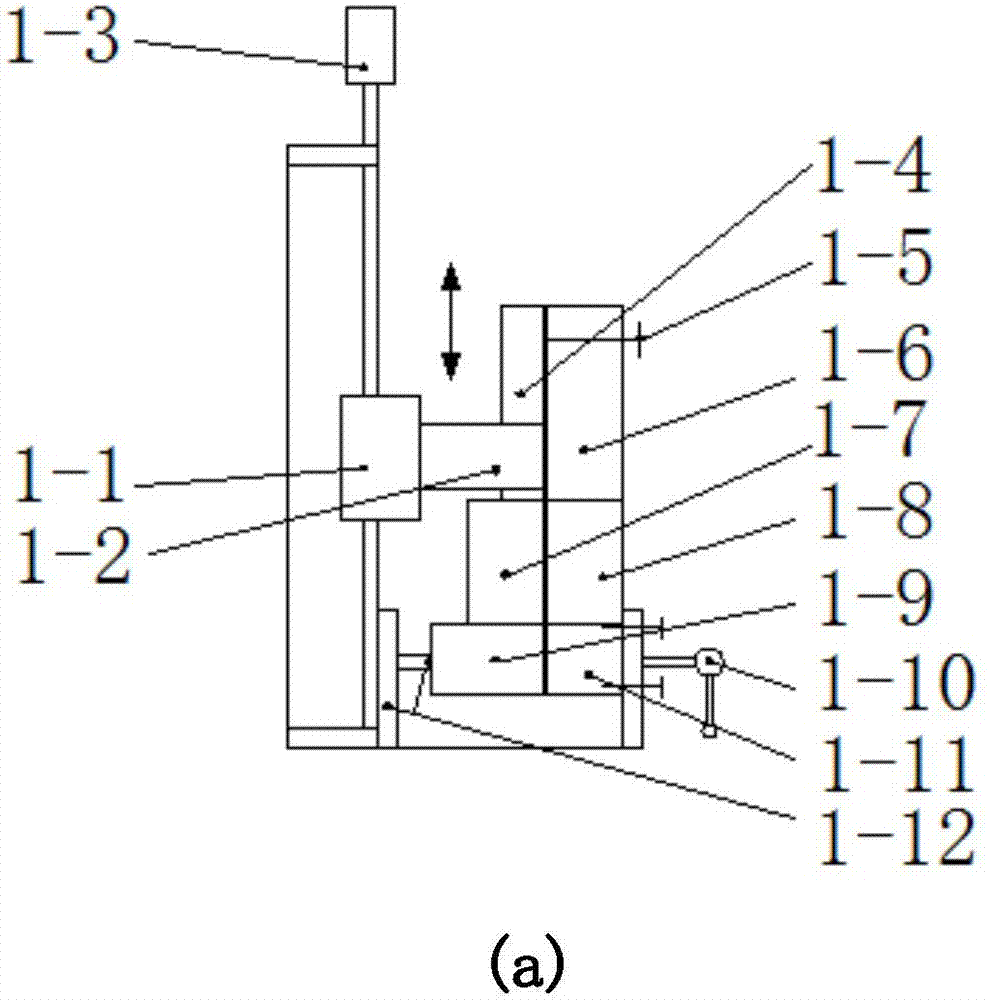

[0025] Such as figure 2 As shown in (a), the slit shape adjustment module 1 includes a vertical slider 1-1, a vertical positioning block 1-2, a first servo motor 1-3, an adjusting bolt 1-5, a standard glass block 1-6, a horizontal Positioning block 1-7, fixture 1-8, horizontal slide block 1-9, handle 1-10, mounting block 1-11 and mounting base 1-12; mounting block 1-11 is fixed on one end of mounting base 1-12; horizontal The two ends of the screw rod are respectively supported on the mounting block 1-11 and the mounting base 1-12 through bearings; the horizontal screw rod end is fixed with a handle 1-10; the mounting block 1-11 is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com