Single-board lens structure

A lens structure and single board technology, applied in installation, optics, instruments, etc., can solve the problems of inconvenient debugging and installation, complex structure, etc., and achieve the effects of easy disassembly, replacement and maintenance, simple structure, and convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

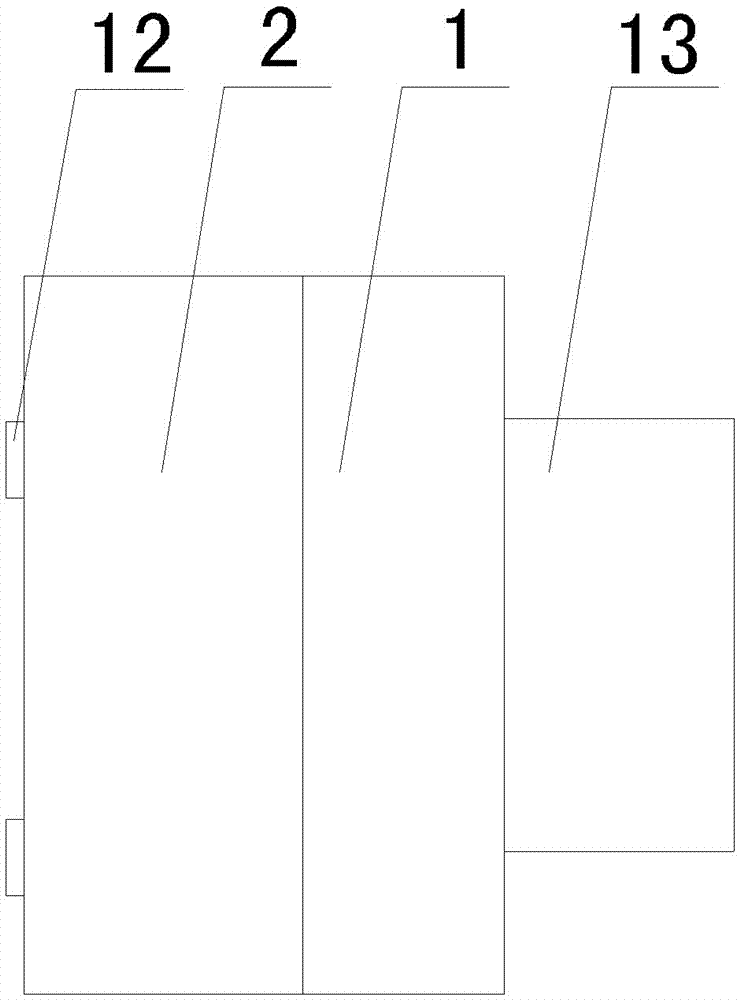

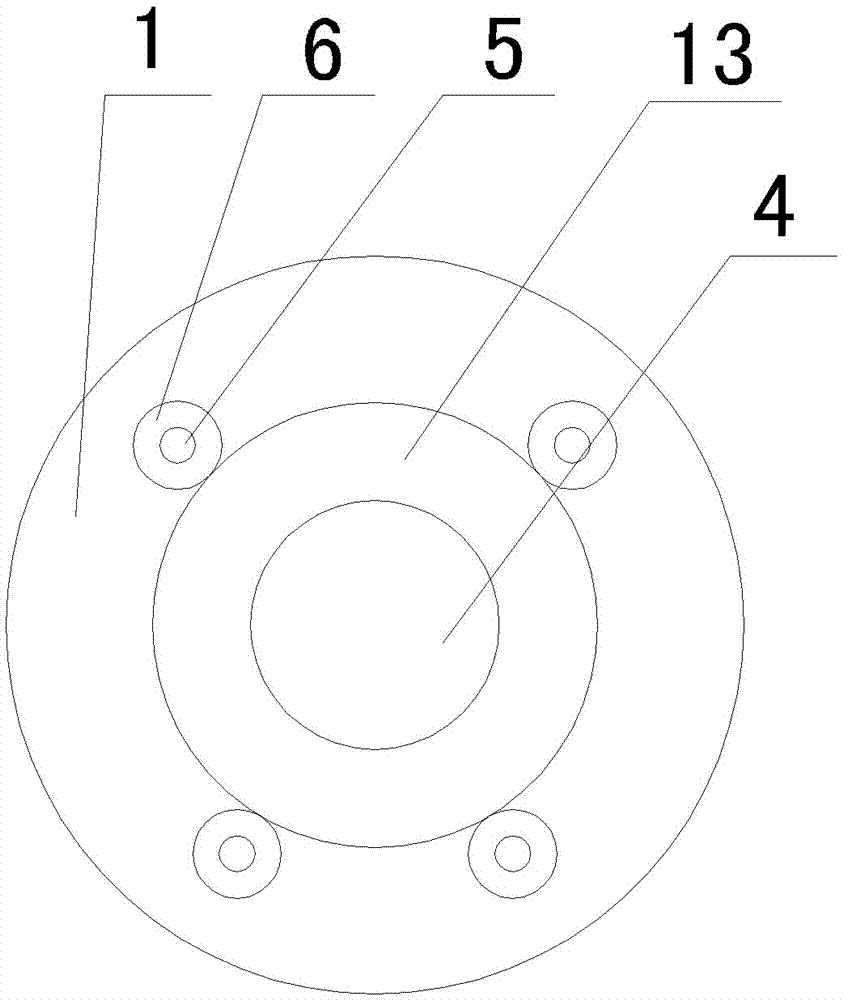

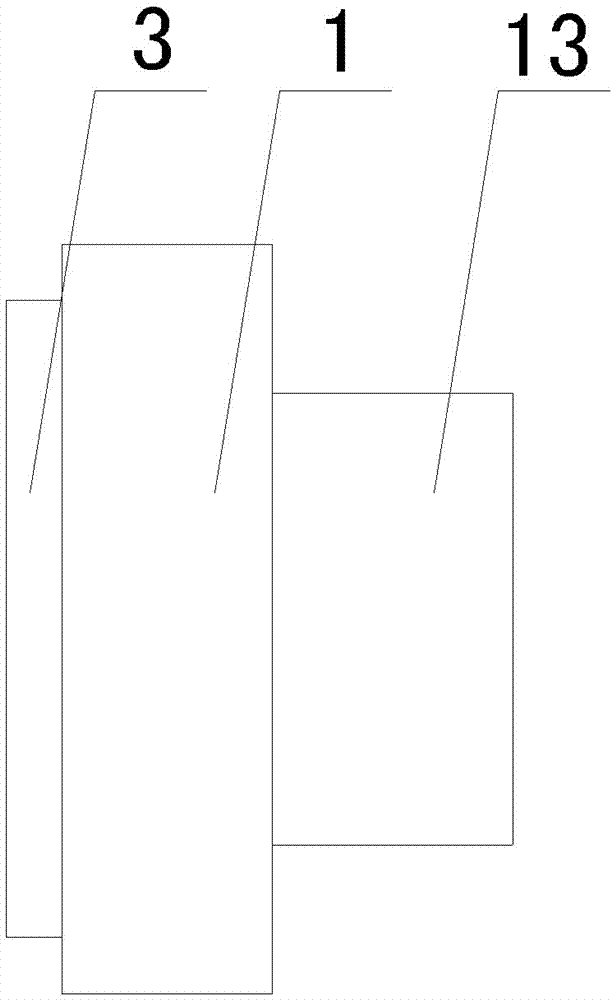

[0011] See figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of veneer lens structure, it comprises the front mirror frame 1 and the rear mirror frame 2 that cooperate with each other, the head of the front mirror frame 1 is provided with the lens projection 13, and the tail is provided with the circular positioning block 3, and the front mirror frame 1 has a front through hole 4 through the front mirror frame 1 in the middle, a front screw hole 5 and a nut hole 6 on the edge of the lens bump 13, and a circular circular positioning block 3 is provided on the head of the rear mirror frame 2. The positioning groove 7, the circular positioning groove 7 is provided with a lens installation groove 8, the lens installation groove 8 is provided with a lens lens, and the rear mirror frame 2 is opened in the middle of the rear mirror frame 2 and corresponds to the front through hole 4. The through hole 9, the side of the lens mounting groove 8 has a gap 10, and the rear mirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com