A fully automatic anaerobic fermentation tank control device and control method thereof

An anaerobic fermentation tank and control device technology, which is applied in the field of food machinery, can solve the problems of long sampling period, large error, and inconvenient sampling operation, and achieve the effects of easy construction, accurate sampling control, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

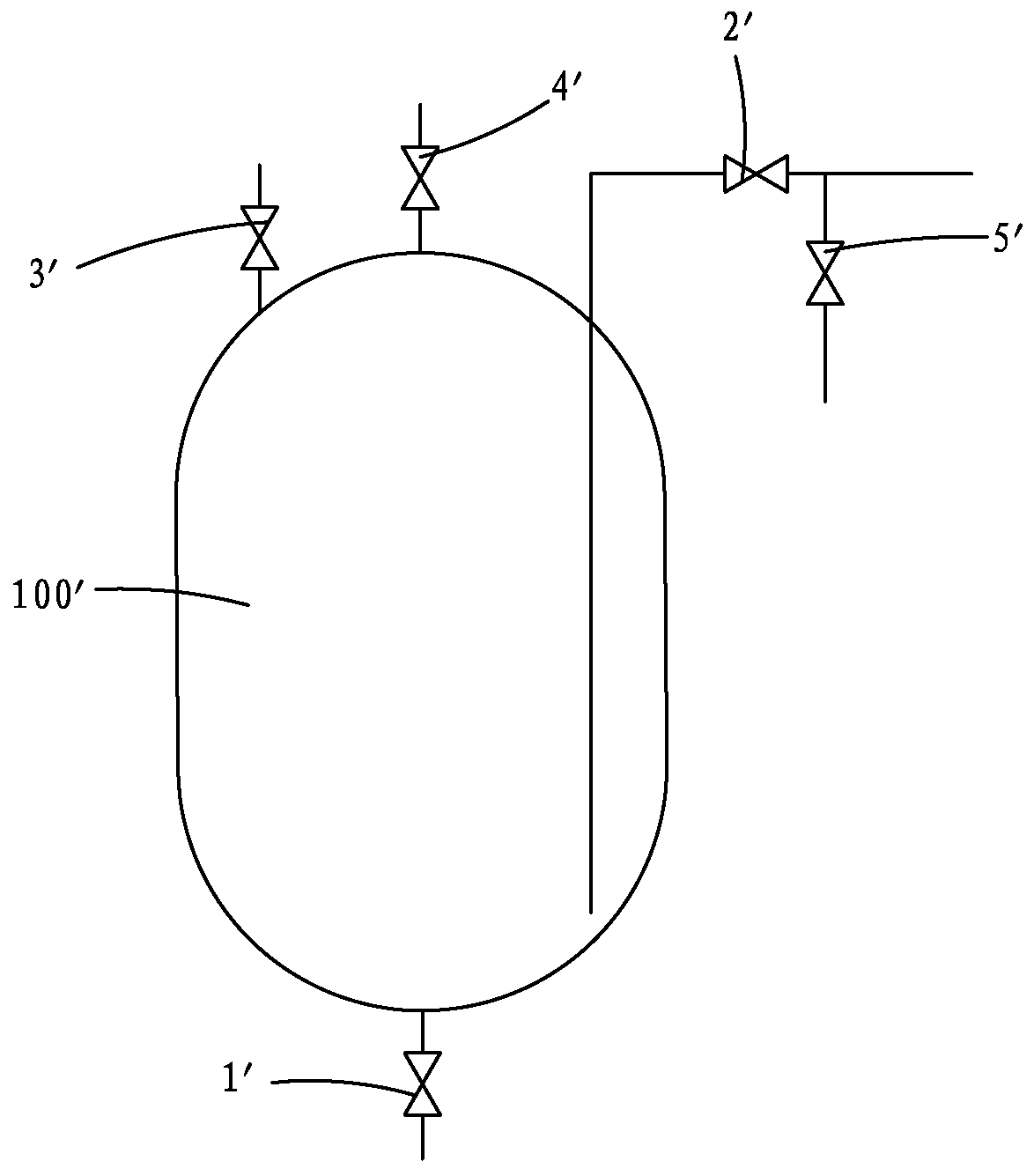

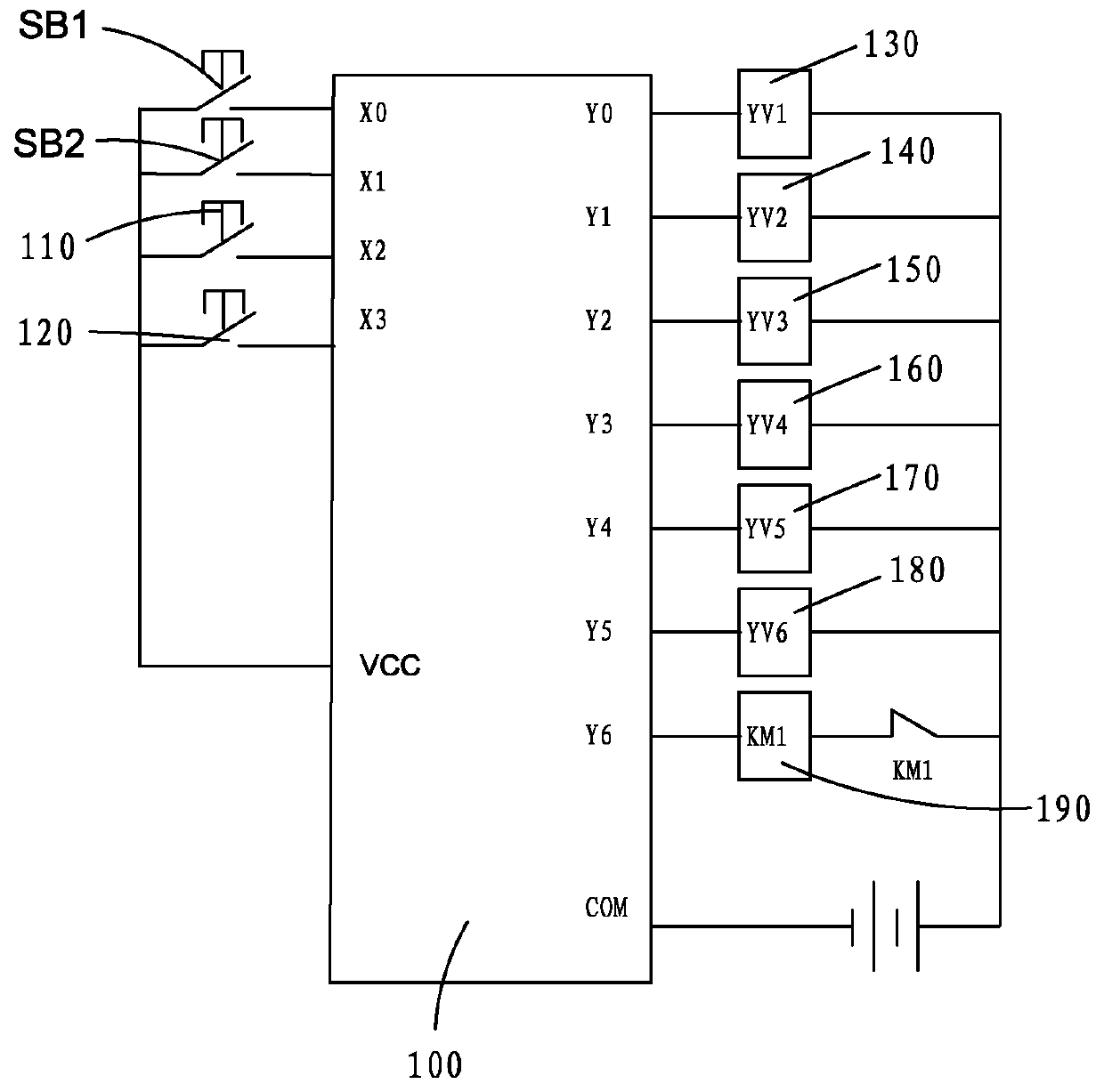

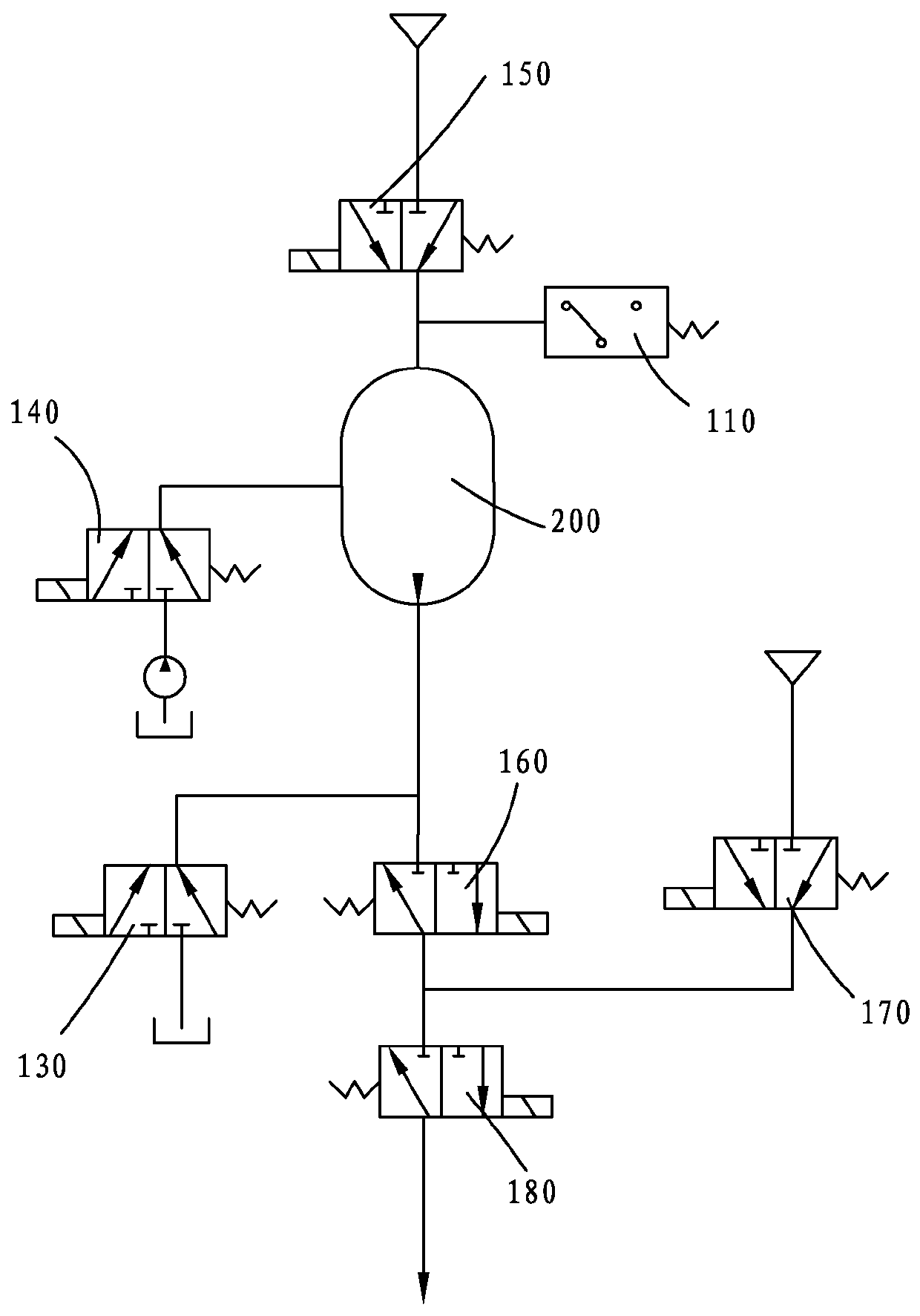

[0038] Embodiment 1, key points please refer to figure 2 and image 3 , a fully automatic anaerobic fermentation tank control device, including a PLC industrial control board 100, the input port X2 of the PLC industrial control board 100 is connected to a pressure relay 110, the input port X3 is connected to a liquid level sensor 120, and the pressure relay 110 and the other end of the liquid level sensor 120 are connected to the power supply terminal VCC of the PLC industrial control board, the pressure relay 110 is arranged on the top of the anaerobic fermentation tank 200, and the liquid level sensor 120 is adjacent to the sampling Next to the test tube 210; the output port Y0 of the PLC industrial control board 100 is connected to a liquid discharge solenoid valve 130, the output port Y1 is connected to a sample adding solenoid valve 140, the output port Y2 is connected to an inflation solenoid valve 150, and the output port Y3 is connected to a lofting solenoid valve. V...

Embodiment 2

[0044] Embodiment 2, a fully automatic anaerobic fermentation tank control method, the control method is based on the described automatic anaerobic fermentation tank control device to perform the following steps:

[0045] Step 1, start, the discharge solenoid valve 130 is charged, and the waste liquid in the anaerobic fermentation tank 200 is removed; at the same time, the timer inside the PLC industrial control board 100 starts timing T1;

[0046] Step 2, when T1 time is up, trigger the charging of the sample adding solenoid valve 140, open the sample adding port, add the sample, and trigger the timer at the same time to start timing T2;

[0047] Step 3, when the time T2 is up, the sample adding solenoid valve 140 is powered off, the sample adding port is closed, and the timer starts timing T3;

[0048] Step 4, when T3 time is up, trigger charging solenoid valve 150, steam solenoid valve 170, and test tube solenoid valve 180, and trigger the timer to start timing T4 at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com