Back-flow preventer used for controlling liquid of micro-fluidic chip and micro-fluidic chip thereof

A technology of anti-reflux device and microfluidic chip, which can be used in fluid controllers, laboratory containers, laboratory utensils, etc., and can solve the problem of insufficient flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

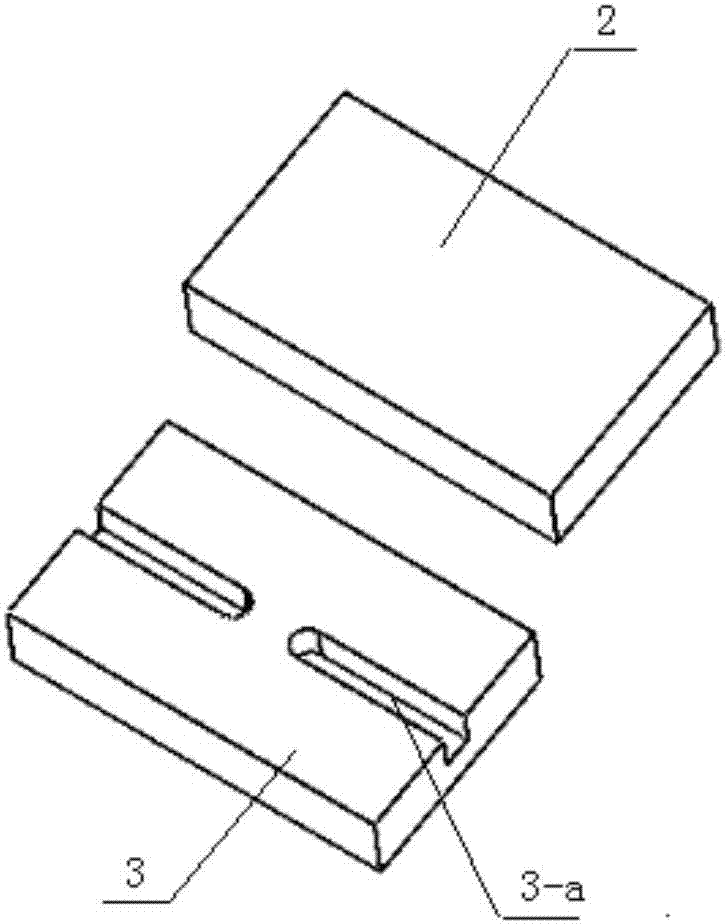

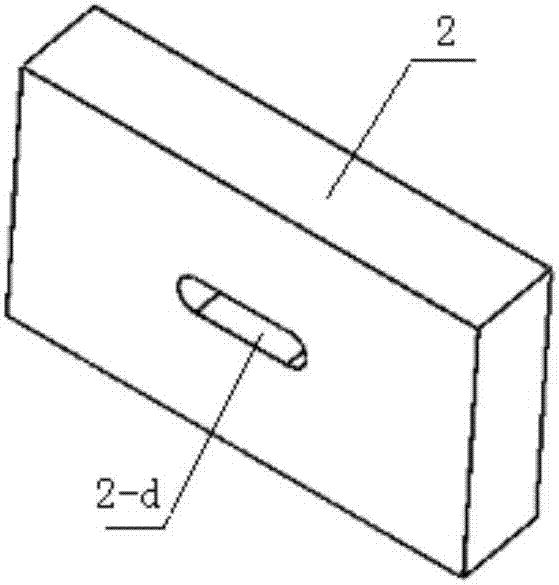

[0042] like Figure 1-2As shown, the anti-backflow structure described in this embodiment includes an anti-backflow channel 2-d (set in the middle chip 2), and the extension direction of the anti-backflow channel 2-d is in line with the microflow at the installation position of the anti-backflow structure. The extension direction of the flow control channel 3-a (set on the lower chip 3) is vertical; the microfluidic flow channel 3-a at the installation position of the backflow prevention structure is divided into two sections by the microfluidic flow channel spacer 3-b, They are the microfluidic liquid inlet channel and the microfluidic liquid outlet channel; the upper end of the anti-backflow channel 2-d is closed, and the lower end is bridged above the microfluidic channel spacer 3-b, and connected to the microfluidic channel spacer 3-b respectively. The fluidic inlet channel and the microfluidic outlet channel are connected; when the air circuit is connected, the fluid in t...

Embodiment 2

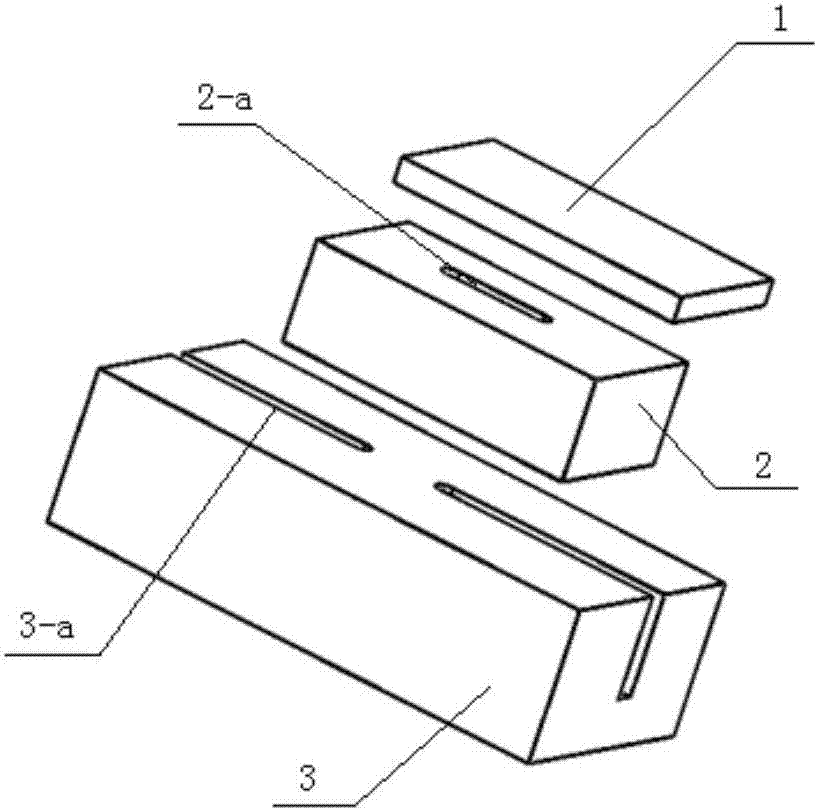

[0045] like Figure 3-4 As shown, the difference between the anti-reflux structure described in this embodiment and Embodiment 1 is:

[0046] 1. The anti-backflow channel 2-d has an anti-backflow bump 2-c, and two anti-backflow communication channels 2-c are formed between the anti-backflow bump 2-c and the anti-backflow channel 2-d b; the two anti-backflow communication channels 2-b are respectively connected with the microfluidic liquid inlet channel and the microfluidic liquid outlet channel; The lower end of -d is flush, and the upper end of the anti-backflow protrusion 2-c is set lower than the upper end of the anti-backflow channel 2-d.

[0047] 2. The upper end of the anti-backflow channel 2-d is closed by the cover provided by the upper chip 1.

[0048] It can be seen from this that the creative anti-backflow structure protruding above the surface of the microfluidic liquid in this embodiment can significantly prevent the backflow of the liquid. At the same time, th...

Embodiment 3

[0050] like Figure 5-8 As shown, the difference between the anti-reflux structure described in this embodiment and Embodiment 2 is:

[0051] The microfluidic channel block 3-b is set as a wedge-shaped block, and the anti-backflow channel 2-d is a wedge-shaped groove similar in shape to the microfluidic channel block 3-b.

[0052] It can be seen from this that since this embodiment has a raised flow channel, it can significantly prevent backflow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com