Active vibration control device and system for electric spindle applicable to high-speed milling processing

A technology of active vibration control and high-speed milling, which is applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as flutter and excessive amplitude, and achieve improved stability, improved processing accuracy and safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

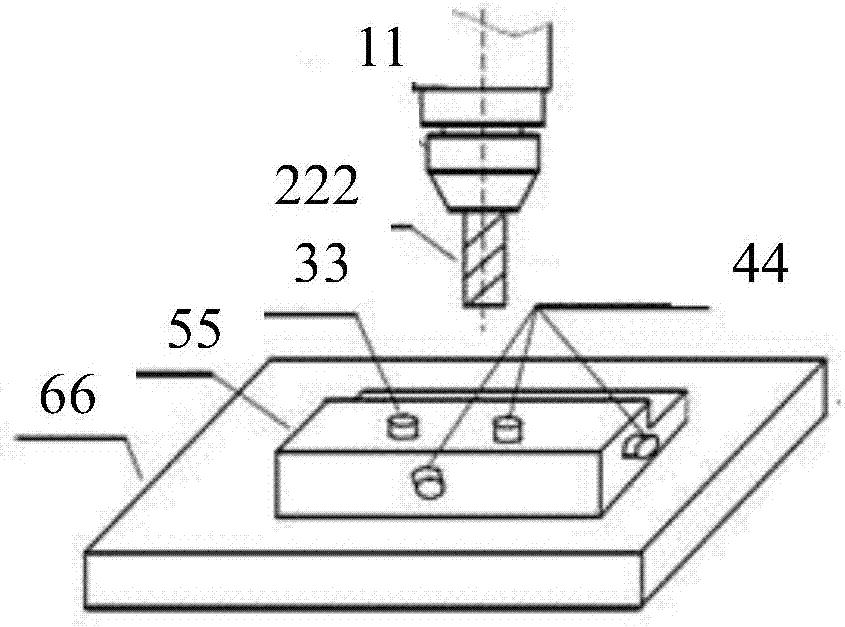

[0017] figure 1 It shows a schematic structural diagram of an active vibration control device for an electric spindle suitable for high-speed milling. The device includes a workbench 6 on which a clamp 5 is provided, and on the clamp 5 is an AE sensor 3 and a vibration sensor 4. The device also includes a milling cutter 2 installed on the main shaft 1. The main shaft 1 is a control device and is connected to a computer. During operation, the sensor on the fixture 5 transmits vibration signals and AE signals to the computer, and the computer controls the Main shaft 1, so as to achieve the purpose of active vibration reduction.

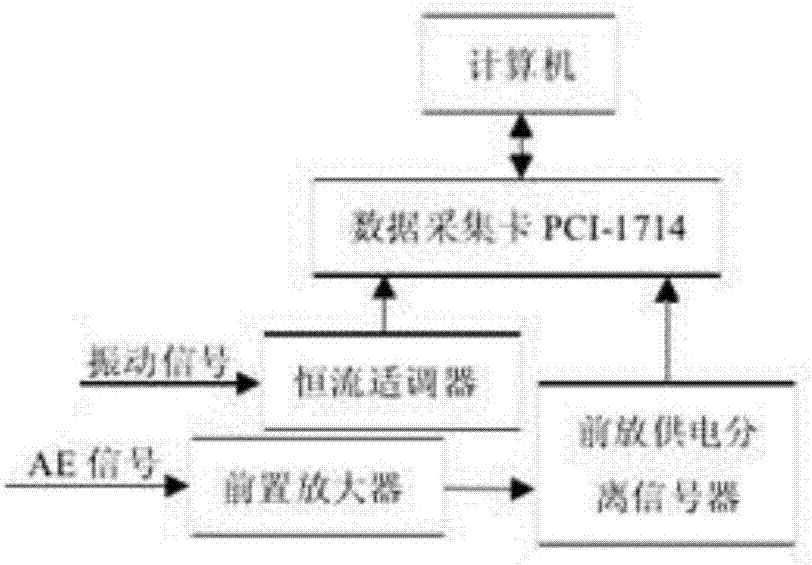

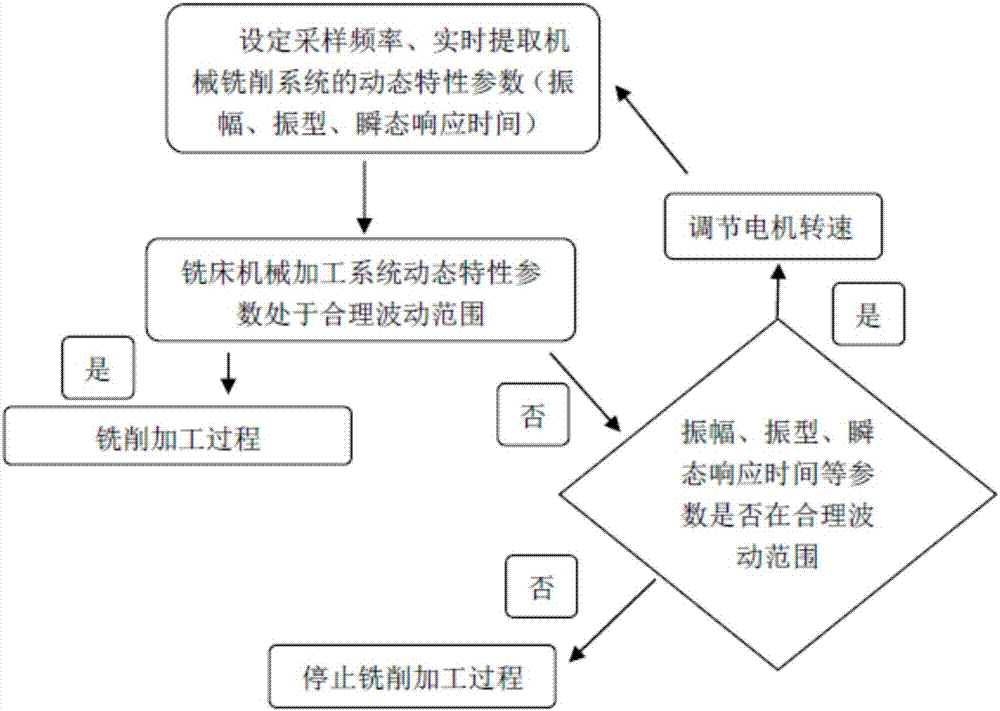

[0018] Figure 2-Figure 4 It shows the control system of the electric spindle active vibration control device suitable for high-speed milling, the system includes a constant current regulator receiving vibration signals, a data acquisition card connected to the output end of the constant current regulator, and a The computer connected to the data acqu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap