A feeding device with secondary feeding function

A feeding and functional technology, which is applied in the field of feeding devices with secondary feeding function, can solve the problems of not having the secondary feeding function, the feedback of ink information is not timely enough, and the stability of the printer is affected. Achieve the effects of simple and ingenious structure, ensuring ink volume, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

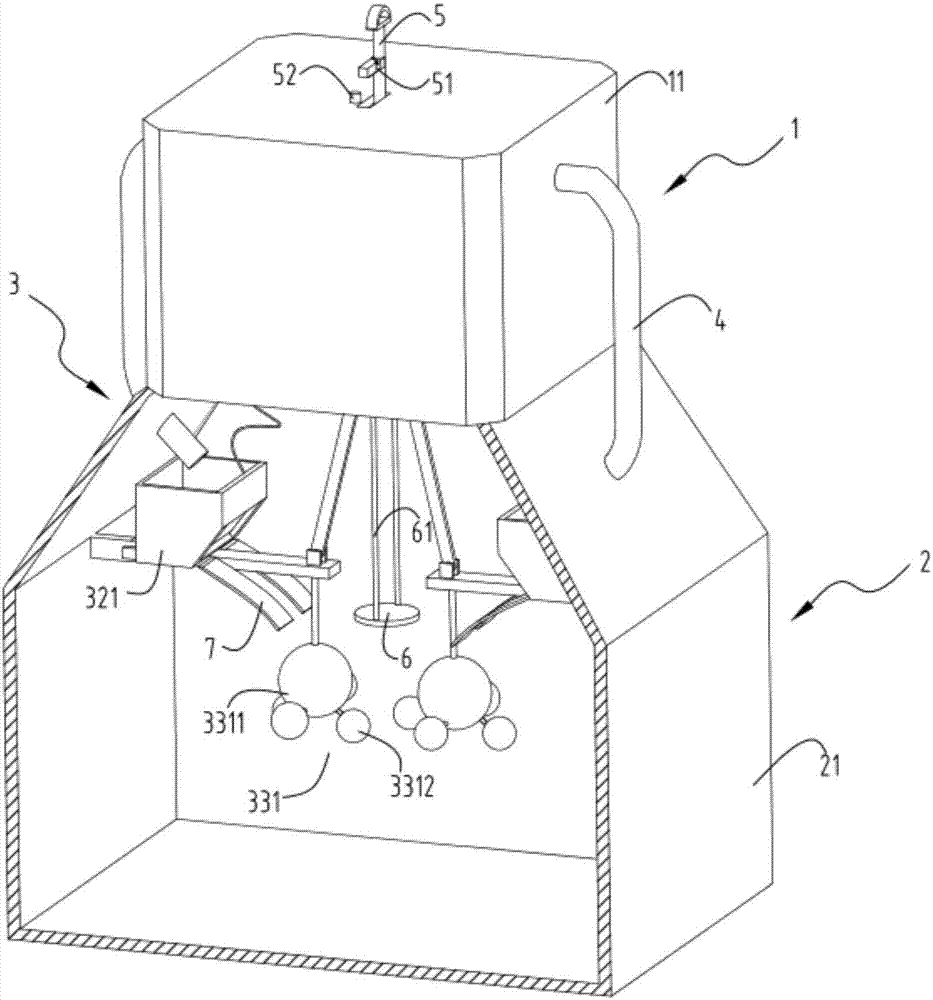

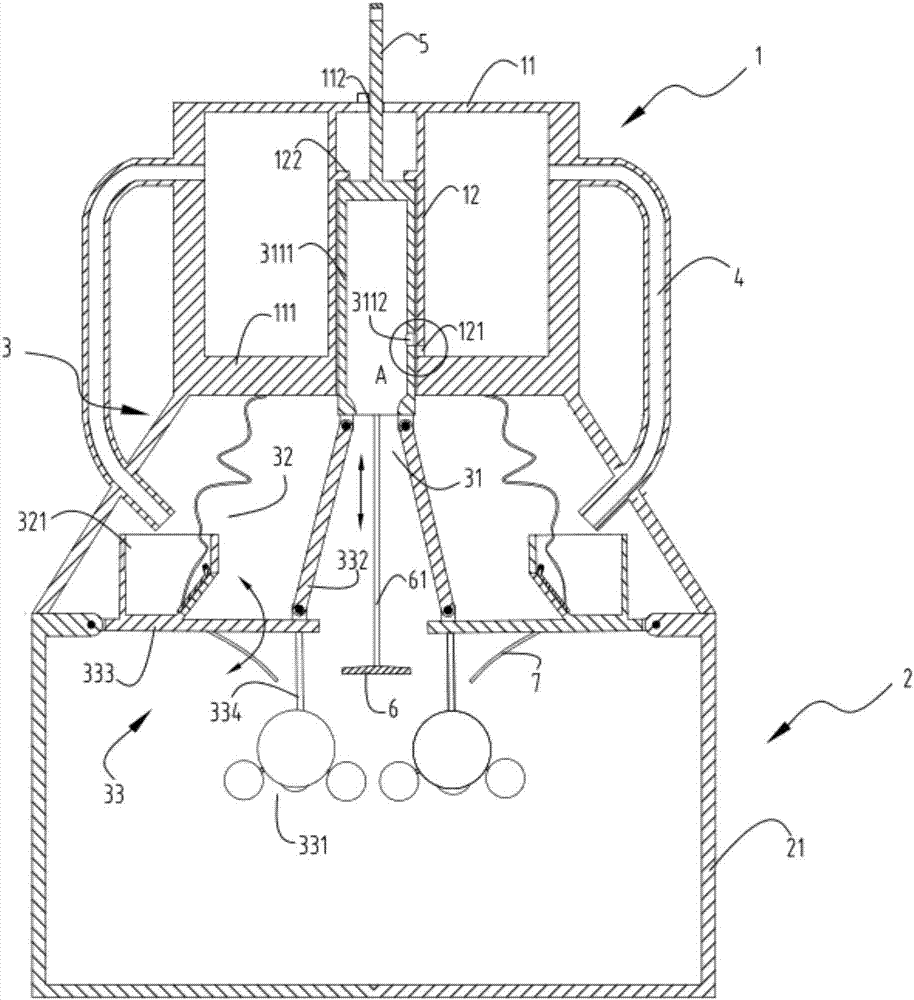

[0036] figure 1 It is a schematic diagram of the structure of a feeding device with a two-stage feeding function, figure 2 Is a schematic cross-sectional view of a refilling device with secondary refilling function, image 3 Is the structure diagram of the feeding mechanism, Figure 4 Is a schematic diagram of the structure of the secondary feeding part, Figure 5 Is the structure diagram of the feeding unit, Image 6 It is a schematic diagram of the external structure of a refilling device with secondary refilling function, Figure 7 Is the structure diagram of the limit device, Figure 8 An enlarged schematic diagram of the guide hole and the discharge hole. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a replenishing device with a two-stage replenishing function includes a feeding unit 1, which is arranged above a working unit 2; and a feeding unit 3, which is arranged on the feeding unit. Between unit 1 and ...

Embodiment 2

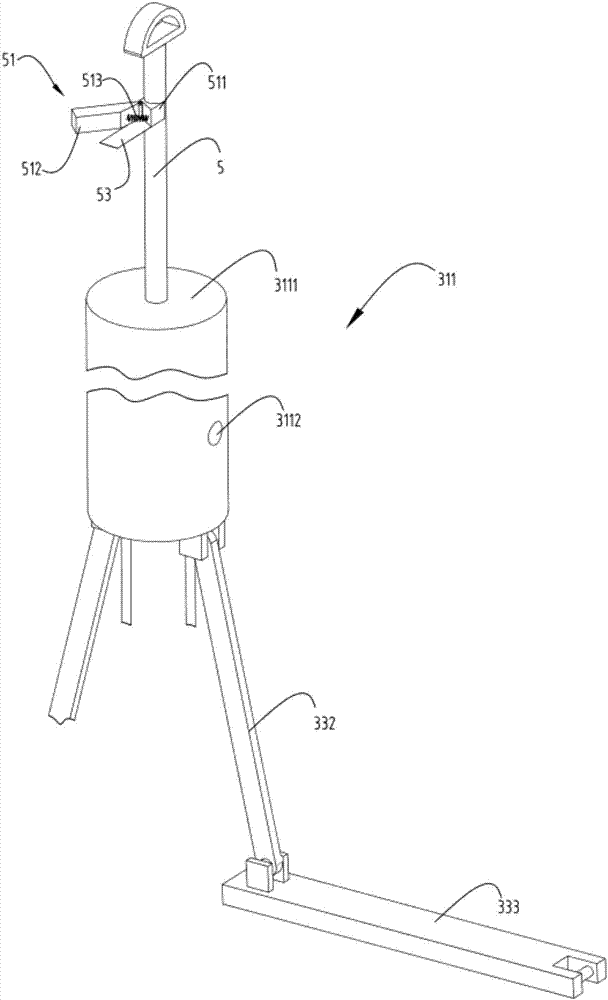

[0044] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to those in the first embodiment. For simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that: further, a drawing rod 5 is provided above the replenishing barrel 3111, and the drawing rod 5 is provided with a guide hole 3112 and a discharge The limiting device 51 communicated with the hole 121, the top cover of the supply box 11 is provided with a through slot 112 for the pull rod 5 to drive the limiting device 51 to move up and down;

[0045] The limiting device 51 includes a fixing seat 511 fixed on the pull rod 5, a limiting block 512 rotatably connected to the fixing seat 511, and a spring 513 connecting the fixing seat 511 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com