Multi-color transfer printing machine

A pad printing machine and ink printing technology, which is applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve problems such as single printing color, reduced efficiency, and inconvenient machine adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

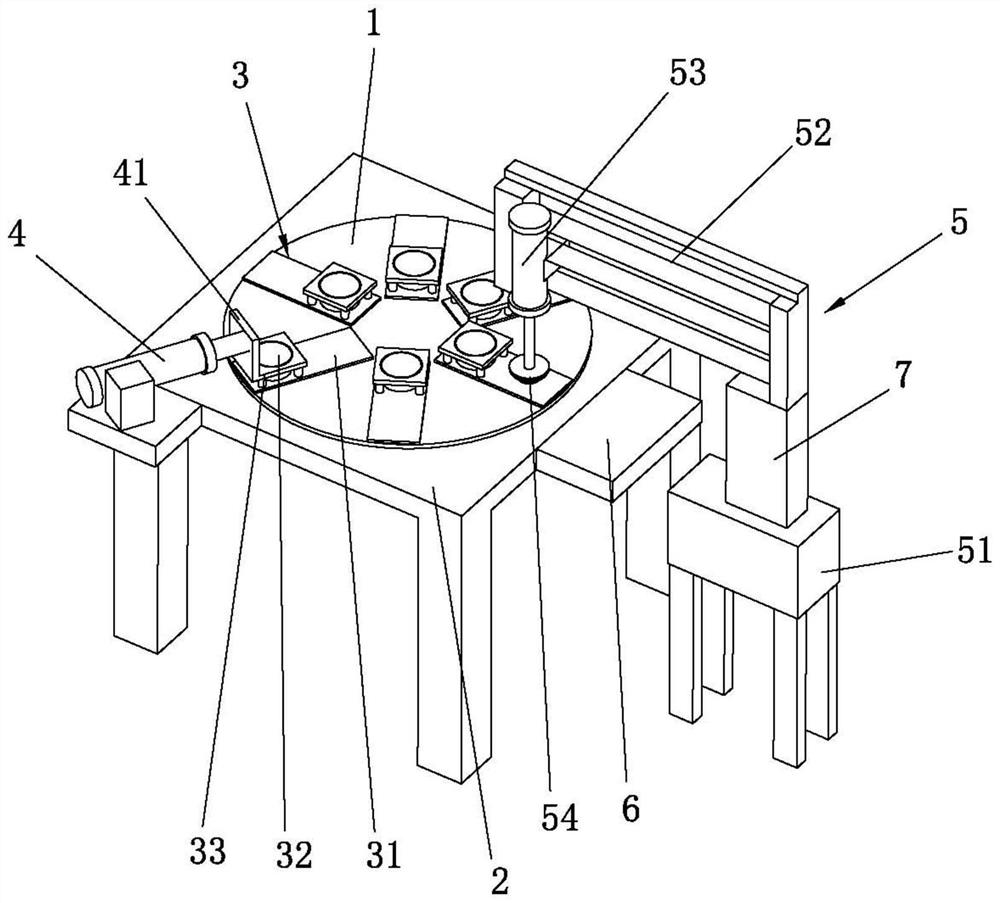

[0019] Such as figure 1 As shown, a multi-color pad printing machine provided by the present invention includes a turntable 1, a rotary drive mechanism 2 for driving the turntable 1 to rotate, a plurality of ink printing molds 3 installed on the turntable 1 and surrounding turntable 1 in turn. The pushing mechanism 4 and the pad printing mechanism 5 arranged in the circumferential direction, a placement platform 6 is arranged below the pad printing mechanism 5, and a plurality of ink printing molds 3 are arranged in a circular array around the central axis of the turntable 1, and the ink printing molds 3 It includes a base, a patterned steel plate 31, an oil cup 32 and a magnetic ring, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com