Thermal transfer printing ink and thermal transfer printing method

A thermal transfer and ink technology, applied in the direction of transfer of ink, ink, and application from the original, can solve the problems of rigid color, single printing effect, no aesthetic feeling, etc., to achieve a fast transfer process, rich layers, and wear resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

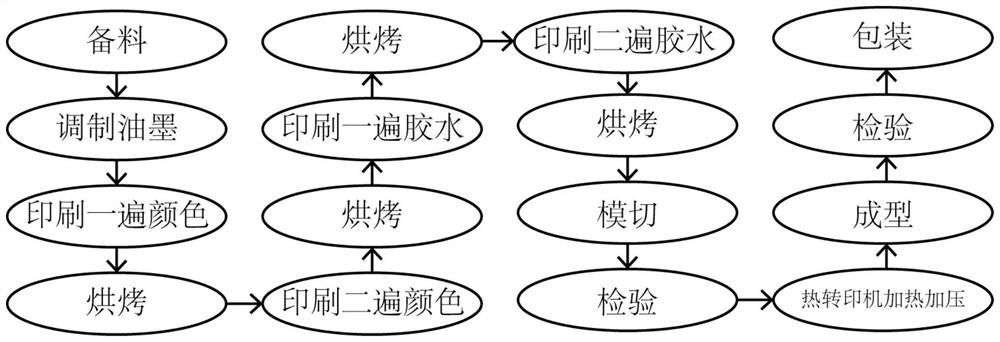

Method used

Image

Examples

Embodiment 1

[0046] The thermal transfer ink of the present embodiment comprises the following components by mass: 70 parts of water-based ink, 10 parts of curing agent and 20 parts of thinner; Water-based ink comprises the following mass ratio components: 60% of water-based PUA, 15% of Water, 20% titanium dioxide and 5% defoamer, dispersant, leveling agent; curing agent includes 1% HM-diisocyanate and 99% HMDI polyisocyanate in mass ratio; diluent includes The mass ratio is 1% ethylene glycol monobutyl ether and the mass ratio is 99% ester solvent.

Embodiment 2

[0048] The thermal transfer ink of the present embodiment comprises the following components by mass: 74 parts of water-based ink, 8 parts of curing agent and 18 parts of thinner; Water-based ink comprises the following mass ratio components: 60% of water-based PUA, 15% of Water, 20% titanium dioxide and 5% defoamer, dispersant, leveling agent; curing agent includes 1% HM-diisocyanate and 99% HMDI polyisocyanate in mass ratio; diluent includes The mass ratio is 1% ethylene glycol monobutyl ether and the mass ratio is 99% ester solvent.

Embodiment 3

[0050] The thermal transfer printing ink of the present embodiment comprises the following components by mass: 78 parts of water-based ink, 7 parts of curing agent and 15 parts of diluent; Water-based ink comprises the following mass ratio components: 60% of water-based PUA, 15% of Water, 20% titanium dioxide and 5% defoamer, dispersant, leveling agent; curing agent includes 1% HM-diisocyanate and 99% HMDI polyisocyanate in mass ratio; diluent includes The mass ratio is 1% ethylene glycol monobutyl ether and the mass ratio is 99% ester solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com