Sand shooting nozzle and core shooting machine comprising same

A technology for sand shooting nozzles and core shooting machines, which is applied in the field of core shooting machines and sand shooting nozzles. It can solve the problems of easy sand leakage and easy clogging of sand shooting nozzles, and achieve the effect of improving air blowing efficiency and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

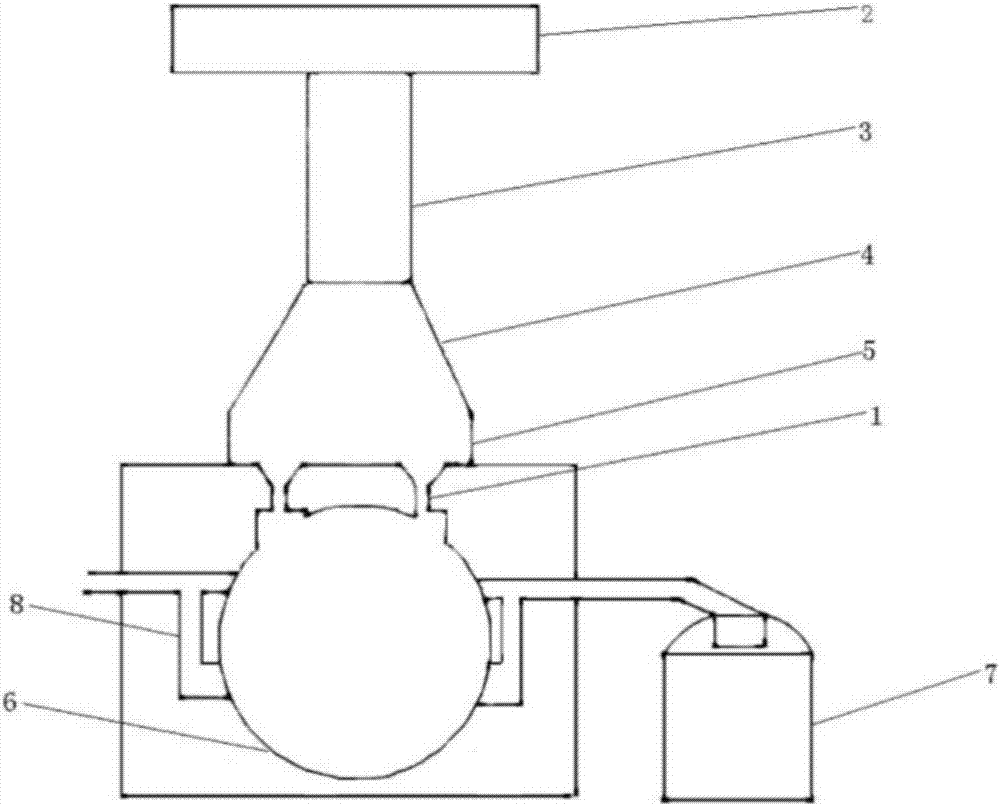

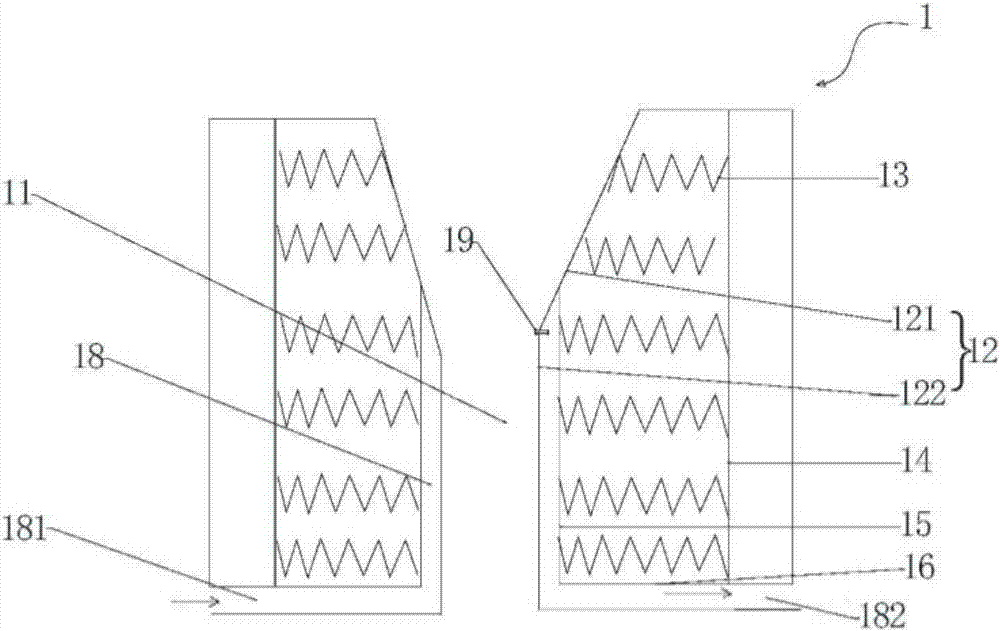

[0019] Such as figure 1 As shown, the core shooting machine of this embodiment includes a sand bucket 2, a sand shooting cylinder 3, a sand shooting bucket 4, a sand shooting plate 5, a sand shooting nozzle 1, a mold 6, a vacuum pump 7, and a vacuum pipeline 8 connected sequentially from top to bottom. , wherein the sand shooting channel 11 surrounding the sand shooting nozzle 5 is provided with a water cooling layer 18, and the water circulation is carried out through the water inlet 181 and the water outlet 182, and a plurality of nozzles are connected in series to form a water cooling system.

[0020] In this embodiment, the thickness of each position of the water-cooling layer is the same, and the flow rate of water can be adjusted through the flow regulating valve as required so that the sand in the sand-shooting channel can be cooled synchronously, which is beneficial to control the thermal curing of the molding sand and prevent the sand-shooting channel from being blocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com