Production method of ethylene-vinyl acetate copolymer resin for solar cell sealing sheet and resin produced by the production method

A vinyl acetate and manufacturing method technology, applied in photovoltaic power generation, etc., can solve the problems of low economy, weak adhesion, peeling, etc., and achieve the effects of low moisture permeability, excellent long-term durability, and high resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

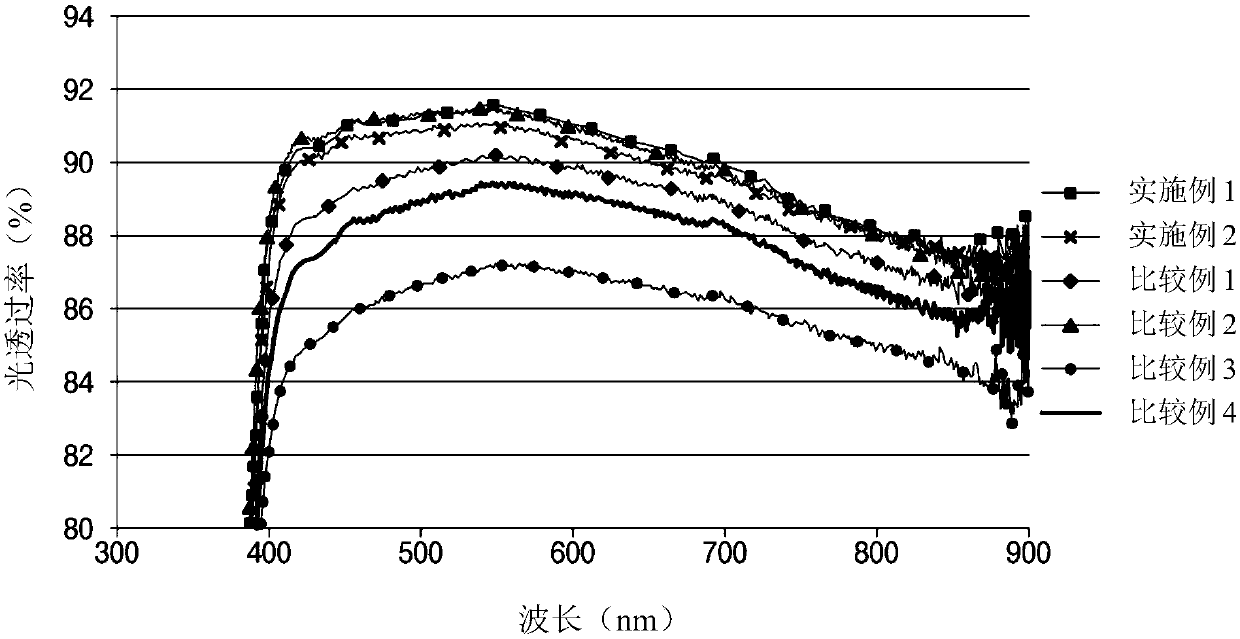

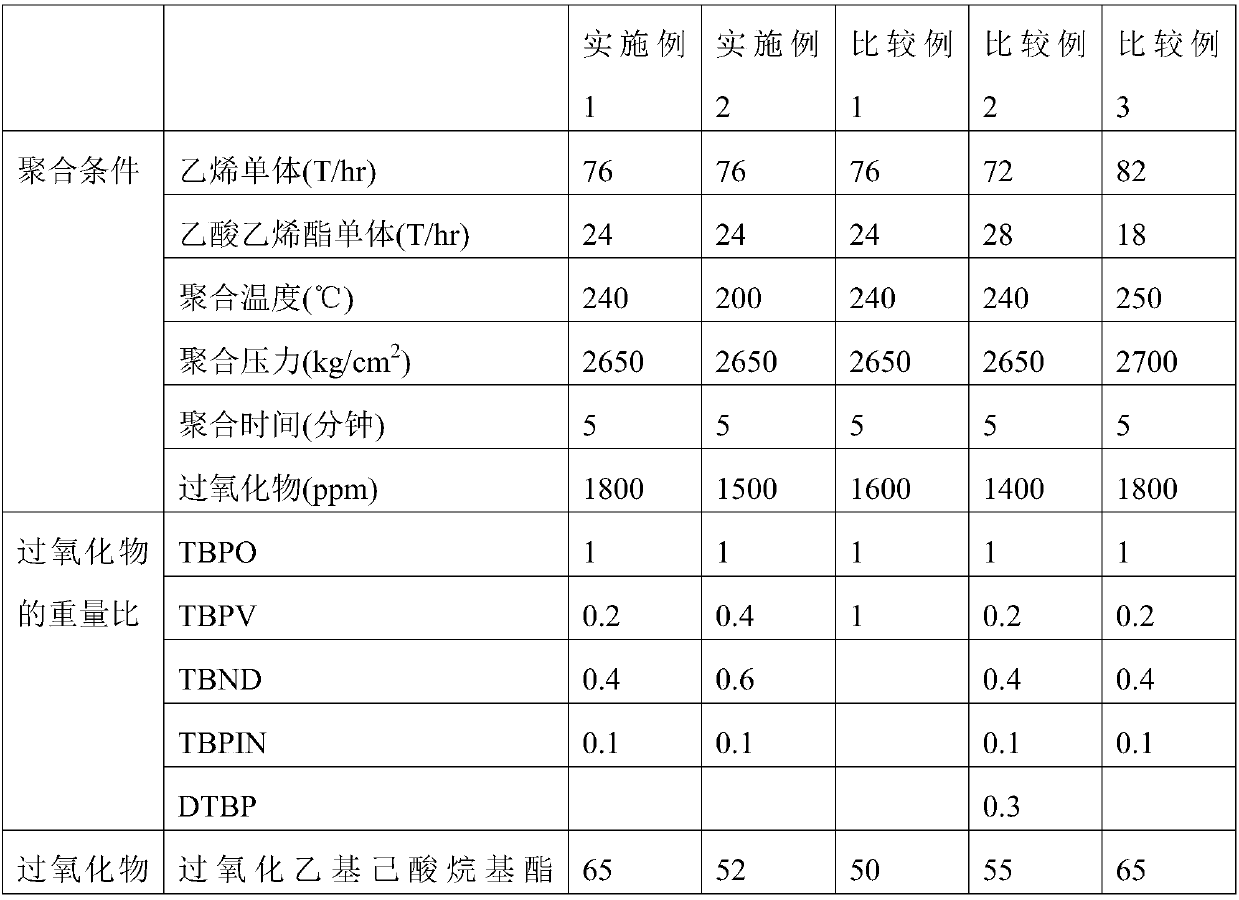

[0047] 76% by weight of ethylene monomer and 24% by weight of vinyl acetate monomer were injected into the tubular reactor as free radical generation initiators to make tert-butyl peroxide 2-ethylhexanoate (TBPO), pivalic acid peroxide The weight ratio of the mixture of tert-butyl ester (TBPV), tert-butyl peroxyneodecanoate (TBND), and tert-butyl peroxy-3,5,5-trimethylhexanoate (TBPIN) is 1:0.2:0.4 : 0.1, 1800ppm compared with ethylene and vinyl acetate monomers, sent to the tubular reactor (tubularreactor) using a high pressure pump, at a polymerization pressure of 2650kg / cm 2 , The EVA resin was produced under the polymerization conditions of a polymerization temperature of 240° C. and a polymerization time of 5 minutes.

Embodiment 2

[0049] 76% by weight of ethylene monomer and 24% by weight of vinyl acetate monomer are injected into the tubular reactor, as a catalyst for generating free radicals, tert-butyl peroxide 2-ethylhexanoate (TBPO), pivalic acid peroxide The weight ratio of the mixture of tert-butyl ester (TBPV), tert-butyl peroxyneodecanoate (TBND), and tert-butyl peroxy-3,5,5-trimethylhexanoate (TBPIN) is 1:0.4:0.6 : 0.1, 1500ppm compared with ethylene and vinyl acetate monomer, using high pressure pump to send to tubular reactor (tubular reactor), at a polymerization pressure of 2650kg / cm 2 , The EVA resin was produced under the polymerization conditions of a polymerization temperature of 200° C. and a polymerization time of 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com