Error correction control method of AGV

A control method and car technology, applied in two-dimensional position/channel control, etc., can solve problems such as stability and safety hazards, improve intelligence and convenience, contribute to safety and stability, avoid cumbersome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] As shown in the figure, the AGV trolley deviation correction control method of the present invention includes the following means.

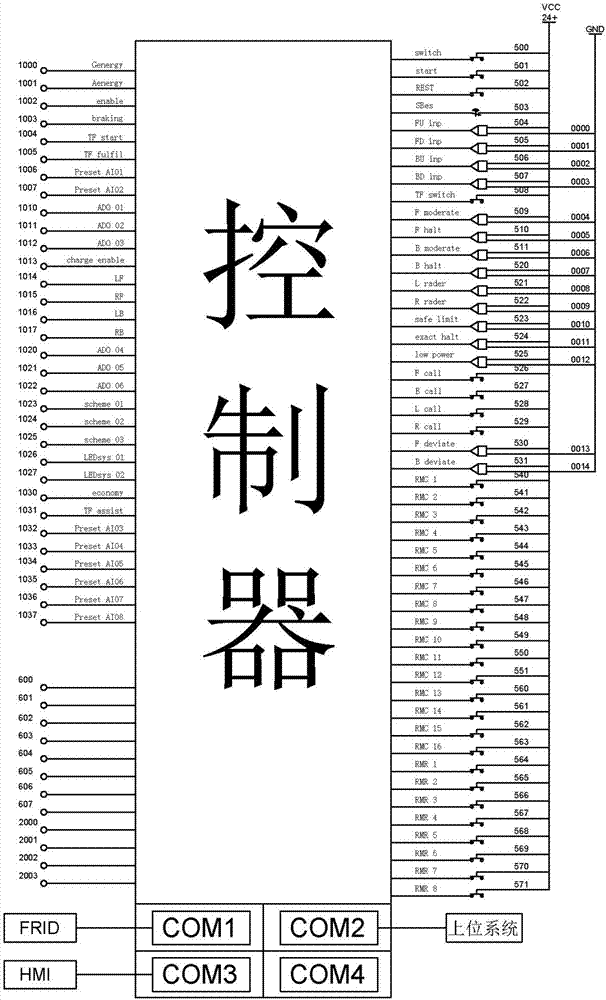

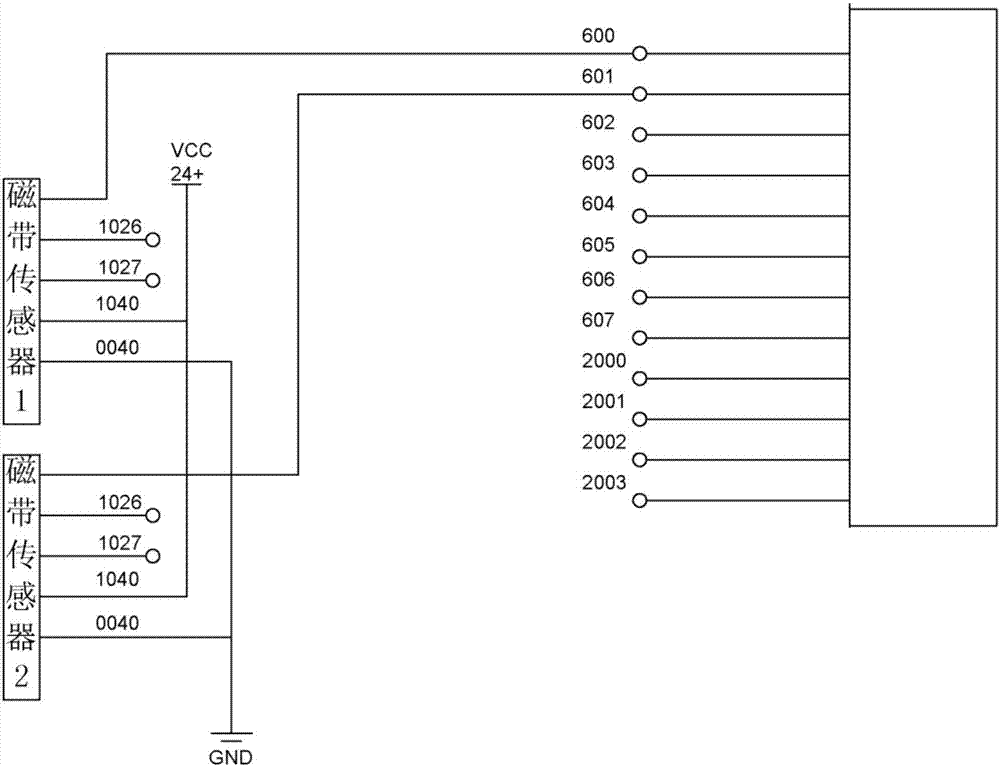

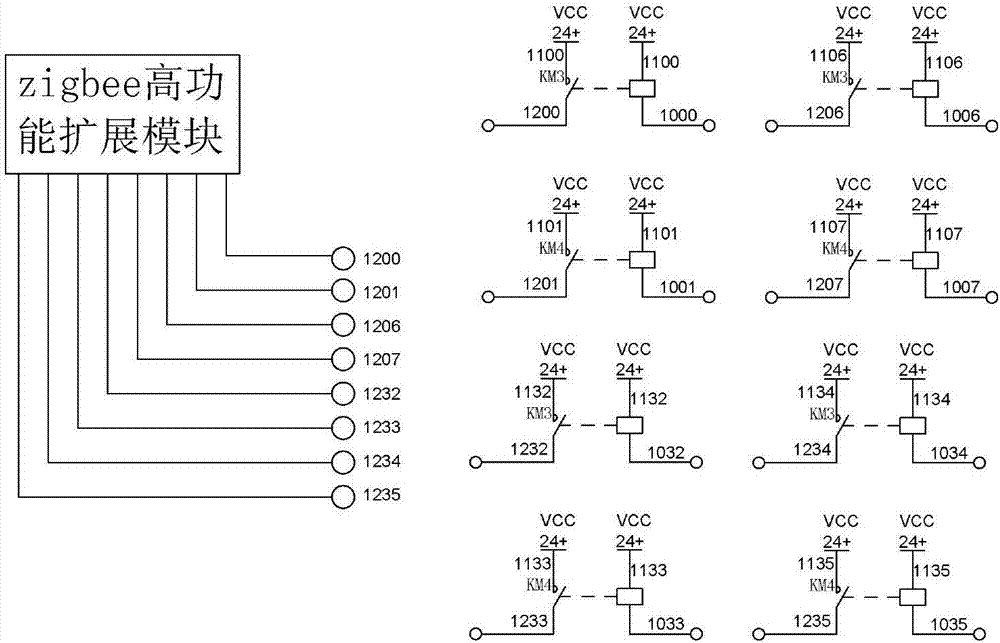

[0017] The magnetic navigation sensor is used to calculate the offset value of the trolley, and the offset value is sent to the main control system to determine the angle of the trolley offset. The main control system adjusts the angular velocity difference between the left and right wheels of the trolley according to the offset value to correct the deviation. The specific way is as follows: figure 1 so and figure 2 As shown, 2 magnetic navigation sensors are connected through 600 and 601. The power supply of the magnetic navigation sensor shares power supply and grounding to suppress differential mode interference. The sensor is equipped with 16 OC gates and corresponding 16 high-sensitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com