Method of multi forming

一种温成形、吹塑成形的技术,应用在多成形领域,能够解决设备成本高、工艺的数目大等问题,达到缺陷率最小化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

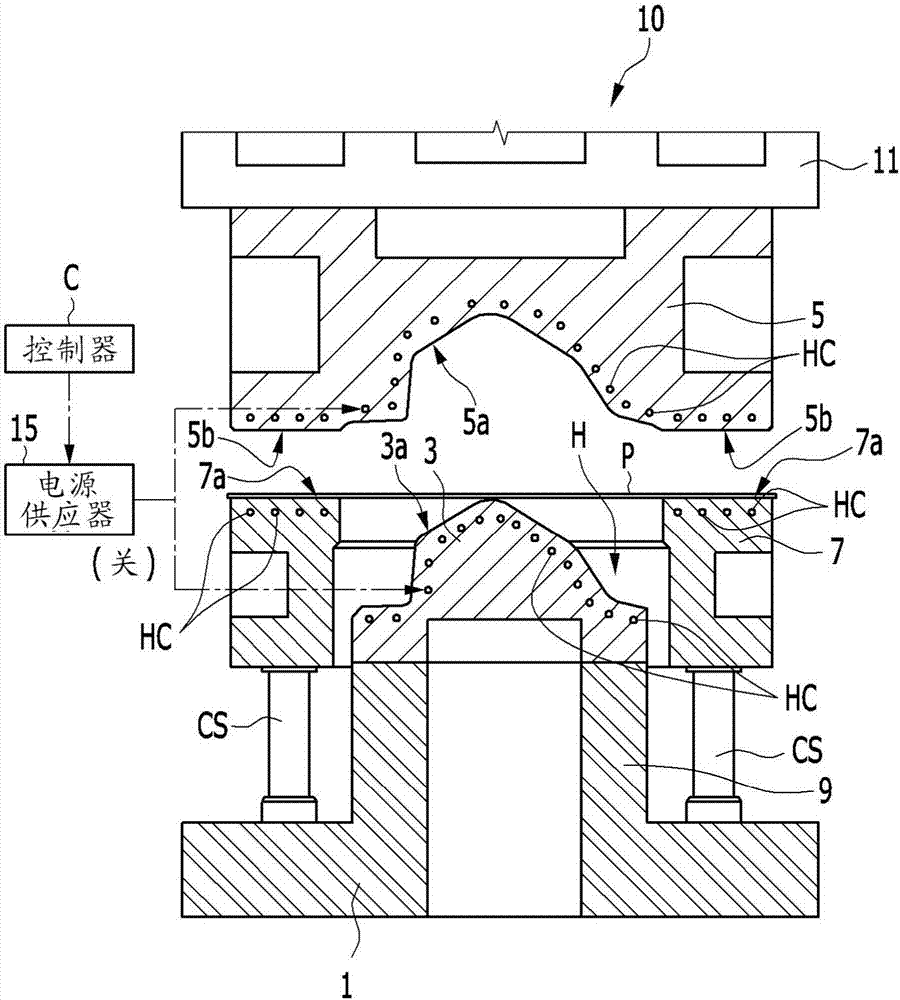

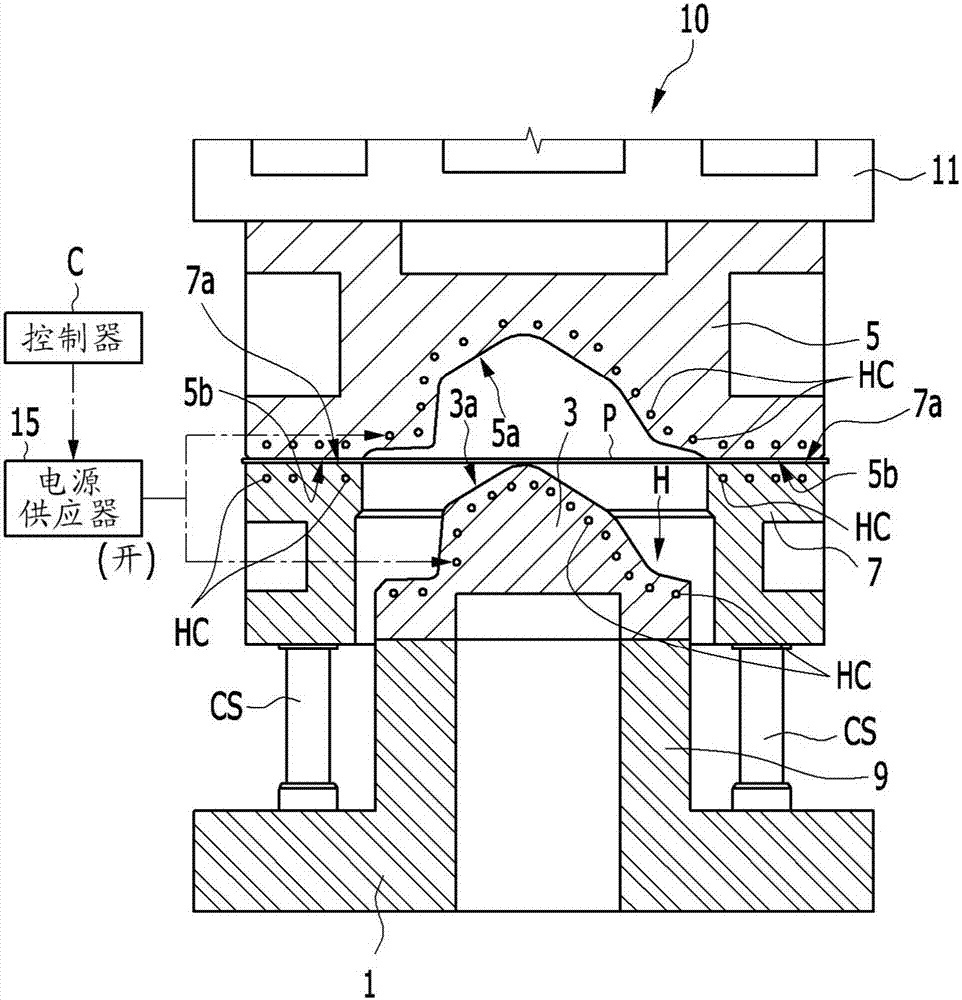

[0041] Hereinafter, exemplary embodiments of the present invention will be described with reference to the accompanying drawings.

[0042] The dimensions and thicknesses of the configurations shown in the drawings are selectively provided for convenience of description, and the present invention is not limited to those shown in the drawings, and in order to clearly describe the present invention, parts irrelevant to this specification will be omitted.

[0043] In an exemplary embodiment of the present invention, each part of the warm forming mold and the blow forming mold is distinguished by a reference numeral.

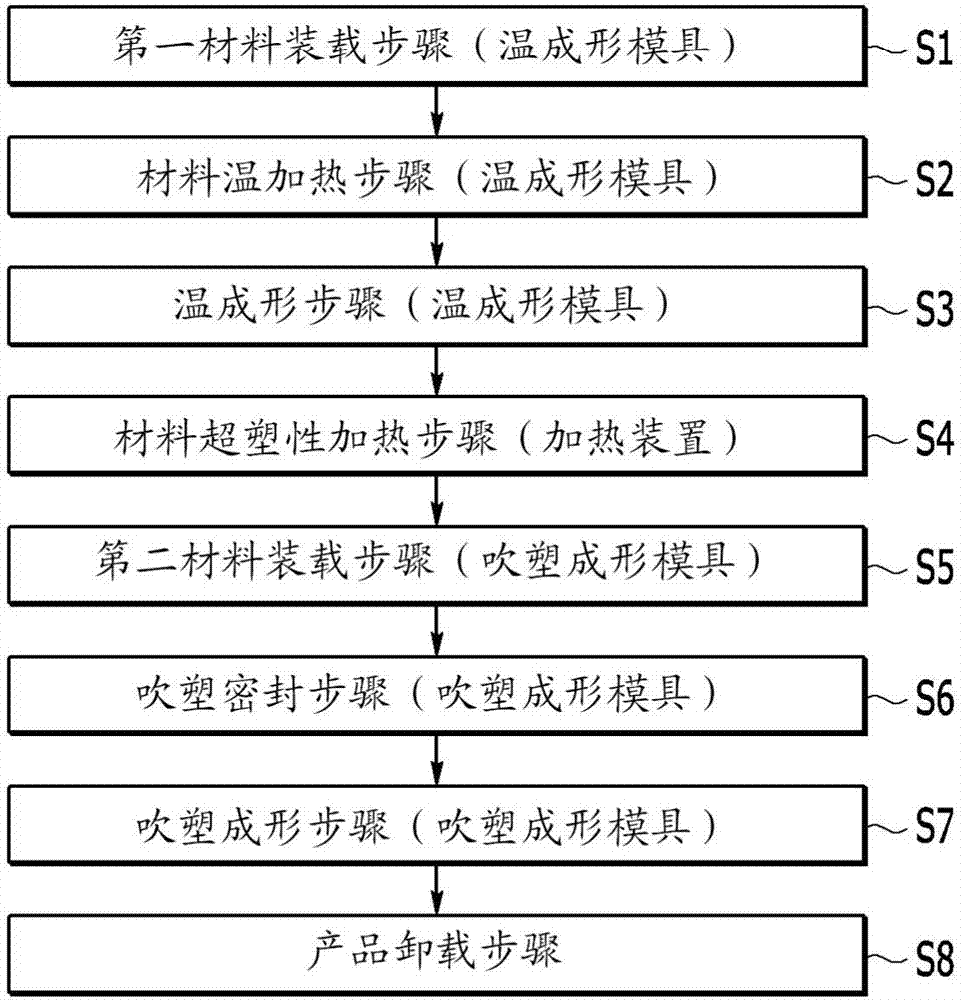

[0044] figure 1 is a step-by-step flow diagram illustrating a multi-shaping method according to an exemplary embodiment of the invention, and Figure 2 to Figure 9 is a step-by-step flowchart illustrating a multi-shaping method according to an exemplary embodiment of the present invention.

[0045] refer to figure 1, according to the multi-forming method of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com