Method for fabricating an electrophoretic display device

A technology of electrophoretic display and equipment, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems such as difficult to perform micro-unit sealing, difficult to form micro-unit partition walls, etc., to achieve quality text, minimize defect rate, high The effect of quality text

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

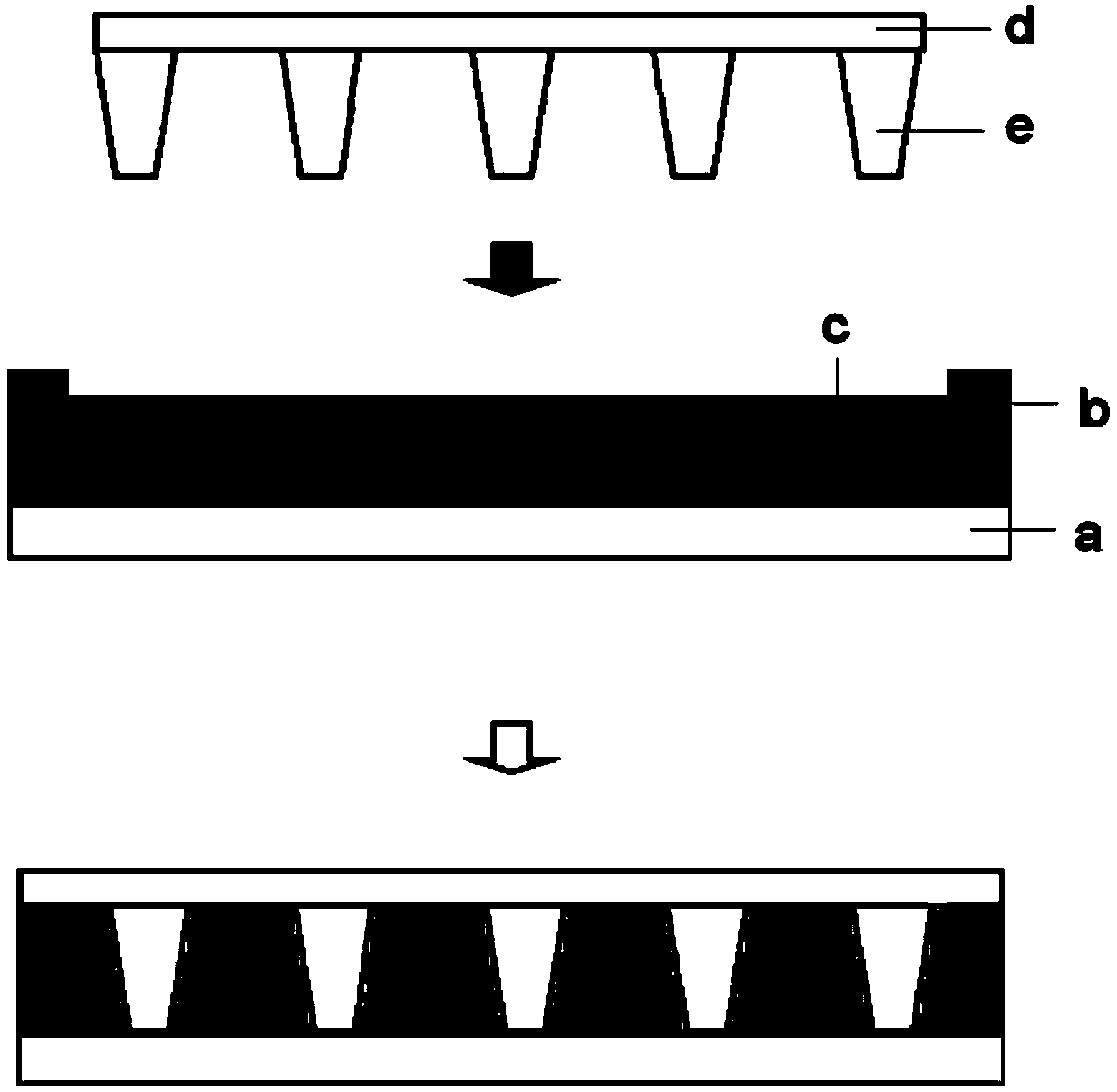

[0133] (1) Forming microcell-shaped partition walls on the first substrate

[0134] Use dry film photoresist ( BU-6200 series, Kolon Industries Co., Ltd.) formed partition walls on ITO / PET film (6 feet long, 5 mm thick).

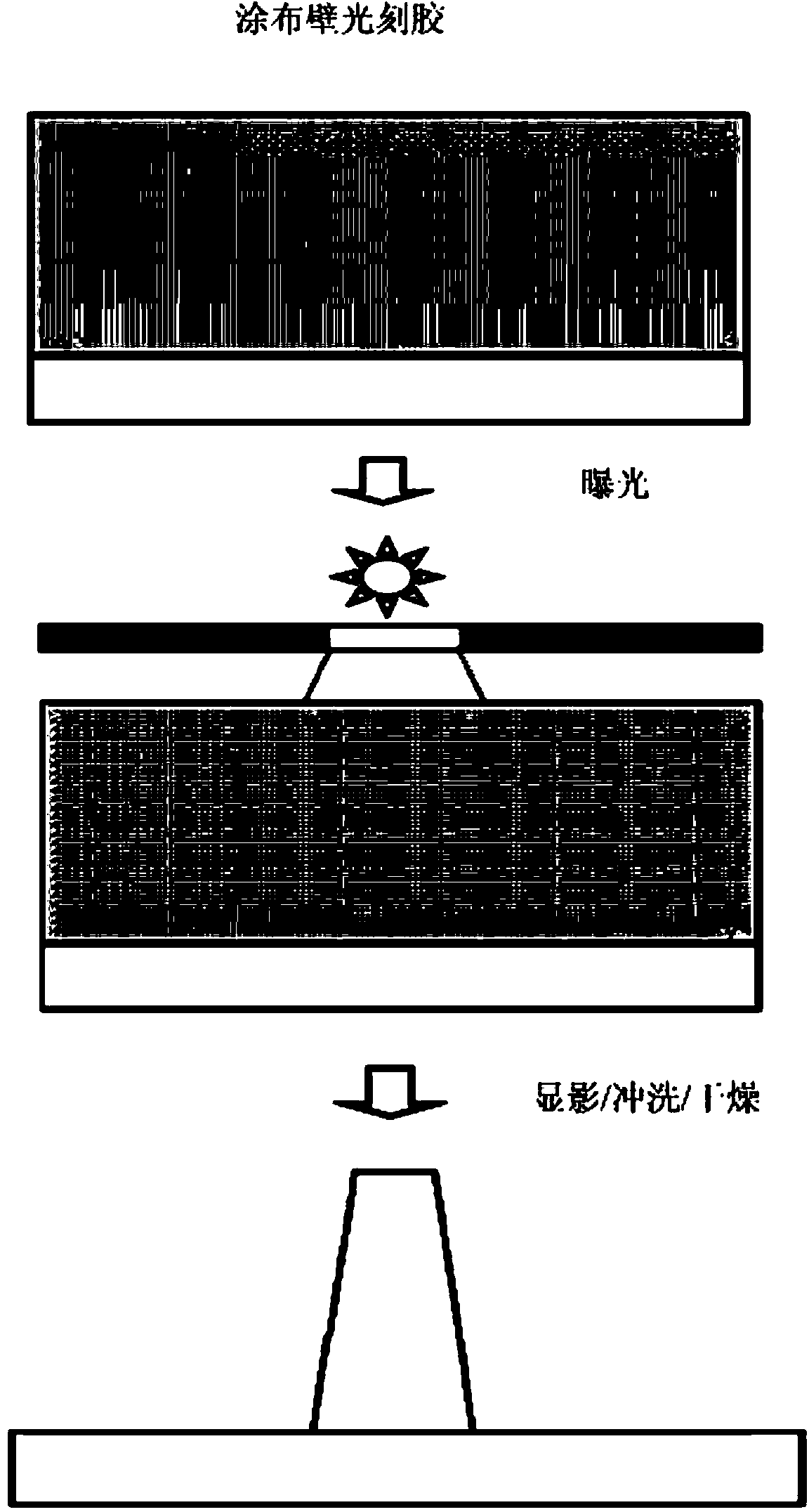

[0135] More specifically, the dry film photoresist is composed of polyimide, binder resin (ie, cross-linked oligomers, such as urethane acrylate or polyester acrylate), photoinitiator and photopolymerization complex solution of monomers. A dry film resist was coated on the ITO / PET film, followed by exposure, development, and rinse using a square mask (longest diagonal: 50 μm) sequentially to form partition walls.

[0136] For this purpose, the section of the partition wall was trapezoidal (upper base 8 μm, lower base 10 μm) and its height was 30 μm.

[0137] (2) Forming a photocurable resin layer and edges on the second substrate

[0138] Spin-coat on ITO electrodes (6 inches) containing transparent acrylic-based photoresist ( Kolon Industries Co., ...

example 2

[0153] (1) Manufactured in the same manner as described in Example 1, except that in the step of forming microcell-shaped partition walls on the first substrate, the partition walls were formed by exposure, development, and flushing using a square mask Electrophoretic display device.

[0154] (2) Observation of the fabricated electrophoretic display device using a reflective digital microscope (Xi-Cam BV410, Bestecvition Co.Ltd.) shows that the results are the same as in Example 1, that is, each micro-unit is uniformly sealed, and there is no Any gap, and the partition wall and the photocurable resin layer are firmly combined without any separation between the two.

[0155] Figure 5 is a partial view of the observed electrophoretic display device.

example 3

[0157] (1) Manufactured in the same manner as described in Example 1 except that the temperature was maintained at 4°C in the step of combining the first substrate having the partition wall and the second substrate having the photocurable resin layer and edges Electrophoretic display device.

[0158] (2) Observation of the fabricated electrophoretic display device using a reflective digital microscope (Xi-Cam BV410, Bestecvition Co.Ltd.) shows that the results are the same as in Example 1, that is, each micro-unit is uniformly sealed, and there is no Any gap, and the partition wall and the photocurable resin layer are firmly combined without any separation between the two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com