Process for preparing saline-alkali soil conditioner from solid waste

A technology for solid waste and saline-alkali soil, applied in the field of solid waste treatment and disposal, can solve the problems of high price and non-environmental protection of saline-alkali soil improvers, and achieve low-cost and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

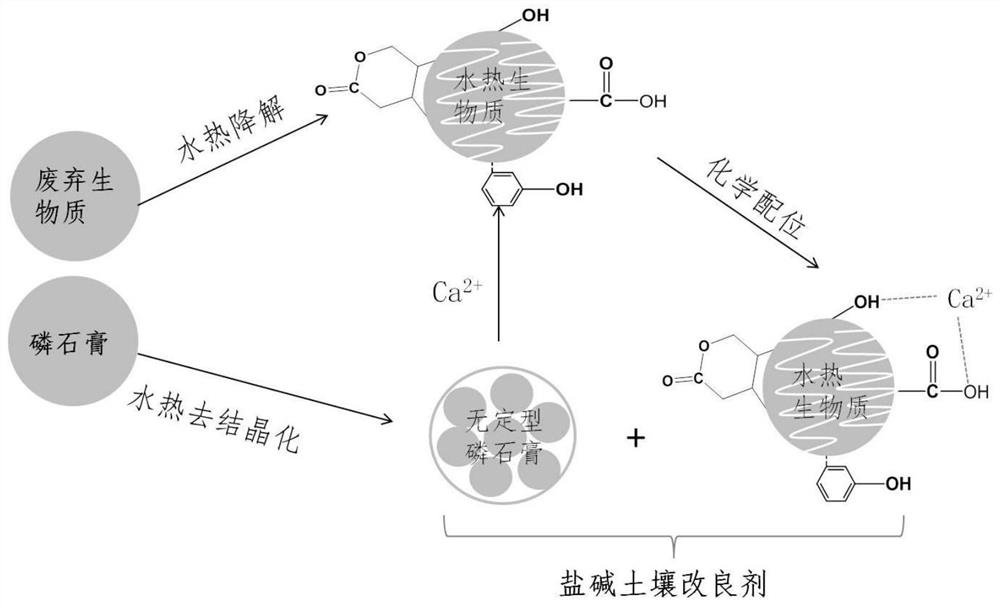

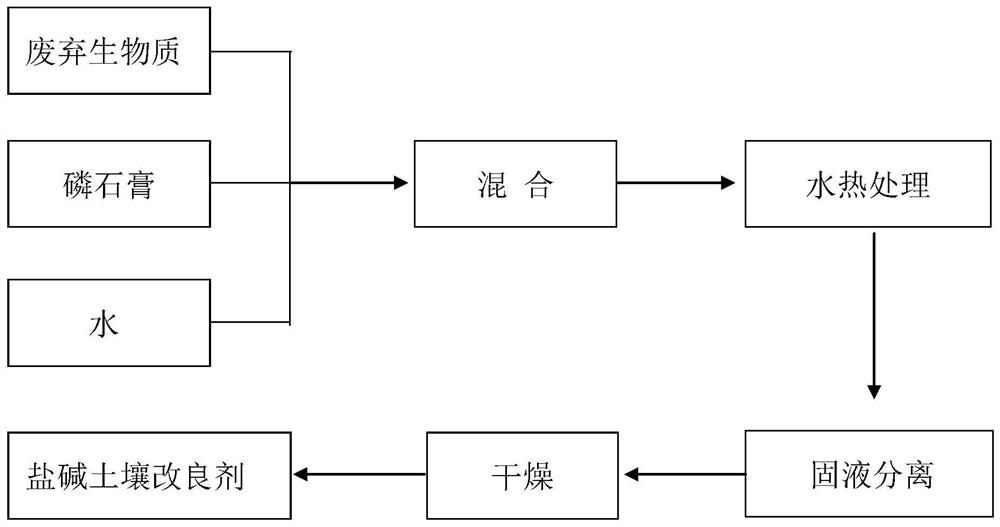

Method used

Image

Examples

Embodiment 1

[0029] 1. Material preparation

[0030] Crush the corn stalks to less than 5mm for later use. Phosphogypsum was taken from a phosphate fertilizer factory in Shandong (main impurities and their content: soluble P 2 o 5 0.11%; insoluble P 2 o 5 0.02%;Al 2 o 3 1.35%; Fe 2 o 3 0.10%; SiO 2 2.4% and Na 2 0.01%). The saline-alkali soil was taken from Weifang, Shandong (salinity 6.5‰, pH value 8.9, belonging to severe saline-alkali soil)

[0031] 2. Preparation of modifier

[0032] 1) Mix corn stalks (dry basis), phosphogypsum, and water in a ratio of 4:1:20, then mechanically stir for 30 minutes;

[0033] 2) After the mixture is transferred to the hydrothermal reactor, it is sealed;

[0034] 3) Heat the reactor to 220°C for hydrothermal treatment, stop heating after 40 minutes of hydrothermal treatment, and naturally cool to room temperature;

[0035] 4) The solid product obtained after the mixture in the reactor is subjected to centrifugal solid-liquid separation...

Embodiment 2

[0062] In addition to using pig manure instead of corn stover.

[0063] In the preparation of the improver 3), the reactor was heated to 240°C for hydrothermal treatment, and the hydrothermal treatment time was 60 minutes;

[0064] In pot experiment 5, 1) add 0.6 gram of improver to 20 grams of soil and then mechanically stir for 30 minutes to make it fully mixed with the same as Example 1.

[0065] The analysis results are shown in Table 1 and Table 2.

example 3

[0067] In addition to improving agent preparation 3), the reactor was heated to 240 ° C for hydrothermal treatment, and the hydrothermal treatment time was 90 minutes;

[0068] In pot experiment 5, 1) add 0.5 gram of improver to 20 grams of soil and then mechanically stir for 30 minutes to make it fully mixed with the same as Example 1.

[0069] The analysis results are shown in Table 1 and Table 2.

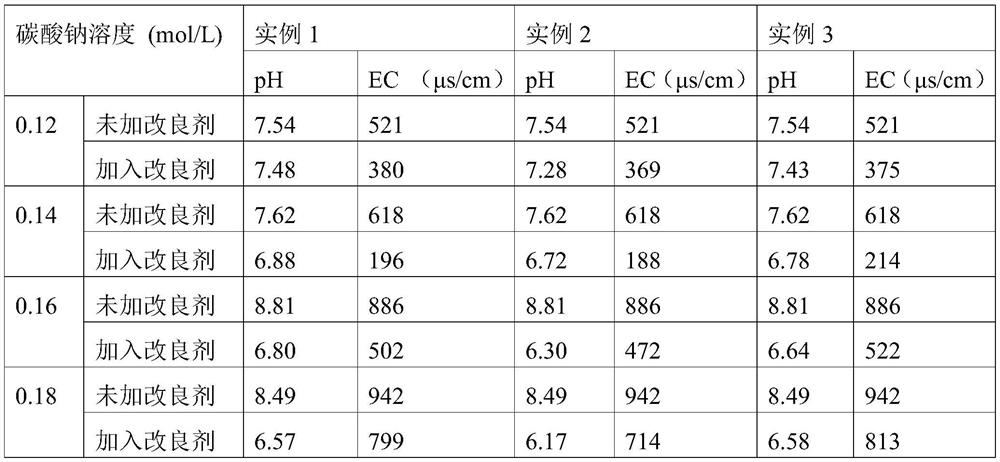

[0070] Table 1. Improvement effect of amendments on saline-alkali soil.

[0071]

[0072]

[0073] Table 2. Effects of amendments on maize growth in saline-alkaline soils.

[0074] time Comparative Test Example 1 Example 2 Example 3 2 4.97 5.14 5.21 5.46 4 6.90 6.99 7.02 7.12 6 14.02 14.95 14.99 15.27 8 24.12 26.20 26.41 27.65 10 29.89 32.23 33.25 35.24 12 33.45 34.59 35.68 37.24 14 34.52 35.64 36.98 37.95

[0075] As can be seen from Table 1, adding the improver prepared by the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com