A multi-capsule hole sealing device for drilling underground coal mines and a hole sealing method thereof

A technology of sealing device and sealing capsule, which is applied in the directions of sealing/isolation, earthwork drilling, wellbore/well parts, etc., which can solve the problem of unsatisfactory sealing pressure measurement effect, long pressure measurement time, sealing hole tightness, etc. Unsatisfactory and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

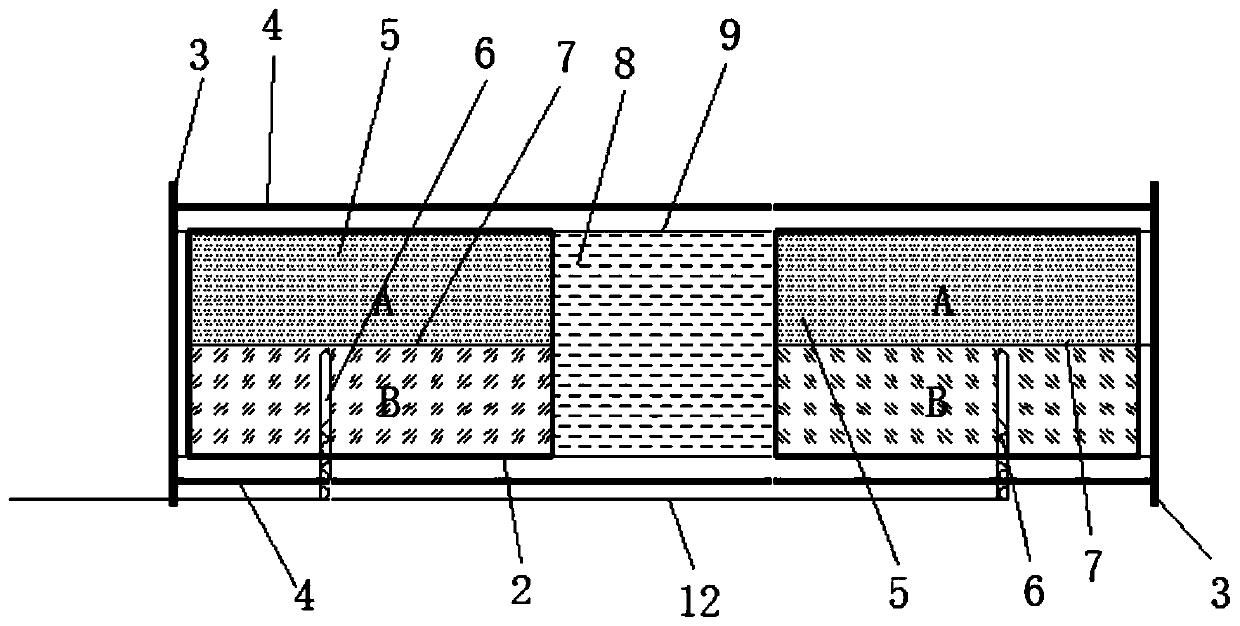

[0020] A multi-capsule hole sealing device for underground drilling in coal mines, comprising baffles 3 at both ends, the baffles 3 are glass fiber reinforced plastic plates, and the baffles 3 at both ends are fixedly connected by rigid connecting rods 4 at four corners . Several sealing capsules 5 are arranged at intervals between the baffles 3 at both ends, and the adjacent sealing capsules 5 are connected by dense screens 9, and the dense screens 9 and the outer surfaces of the sealing capsules 5 jointly form a mucus cavity, and the mucus The lumen is pre-filled with mucus8. Such as figure 1 As shown, two sealing capsules 5 are included in this embodiment.

[0021] The sealing capsule 5 includes a capsule body 2 made of elastic material. The capsule body 2 is provided with a diaphragm 7 that separates the interior space of the capsule body into two separate chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com