A micro-fracture micro-nano plugging material for drilling and its preparation method

A technology for plugging materials and micro-cracks, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve problems such as large size and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] (1) Weigh 80 parts of paraffin and 100 parts of white oil into a beaker and melt at 70°C; after melting completely, carry out slow magnetic stirring, and add 40 parts of composite surfactant during this process; after completely dissolving , slowly add 200 parts of tap water dropwise; stir for another 20 min, stop stirring after cooling down, and take samples to test the performance.

[0019] (2) Weigh 200 parts, 250 parts, and 300 parts of ultrafine calcium carbonate of 500 mesh, 1000 mesh, and 2500 mesh respectively, put the three into a closed stirring container, stir at high speed for 30 minutes, and wait for all the powders to settle completely.

[0020] (3) Add 100 parts of the prepared paraffin nanoemulsion to the mixer, and gradually mix 200 parts of the prepared composite ultrafine calcium carbonate into the nanoemulsion at the speed of the mixer at 3000r / min, and then mix it at 10000r / min Stir for 30 minutes at a high speed to fully mix the two to obtain the p...

example 2

[0022] (1) Weigh 100 parts of paraffin and 80 parts of white oil and add them to the stirrer, melt at 75°C; after the melting is complete, carry out slow magnetic stirring, and add 50 parts of composite surfactant during this process; wait for complete dissolution Finally, slowly add 250 parts of tap water dropwise; stir for another 25 min, stop stirring after cooling down, and take samples to test the performance.

[0023] (2) Weigh 250 parts, 200 parts, and 300 parts of ultrafine calcium carbonate of 500 mesh, 1000 mesh, and 2500 mesh respectively, put the three into a closed stirring container, stir at high speed for 30 minutes, and wait for all the powders to settle completely.

[0024] (3) Add 200 parts of the prepared paraffin nanoemulsion into the high mixing cup, and gradually mix 300 parts of the prepared composite ultrafine calcium carbonate into the nanoemulsion at the speed of the mixer at 3000r / min, and then mix it at 10000r / min Stir at a speed of 30 min for 30 mi...

example 3

[0026] (1) Weigh 120 parts of paraffin and 120 parts of white oil into a beaker and melt at 80°C; after melting completely, carry out slow magnetic stirring, and add 60 parts of composite surfactant during this process; after completely dissolving , slowly add 300 parts of tap water dropwise; stir for another 30 min, stop stirring after cooling down, and take samples to test the performance.

[0027] (2) Weigh 300 parts of 500-mesh, 1000-mesh, and 2500-mesh ultrafine calcium carbonate respectively, put the three into a closed stirring container, stir at high speed for 30 minutes, and wait for all the powders to settle completely.

[0028] (3) Add 150 parts of the prepared paraffin nanoemulsion to the high mixing cup, and gradually mix 400 parts of the prepared composite ultrafine calcium carbonate into the nanoemulsion at the speed of the mixer at 3000r / min, and then mix it at 10000r / min Stir at a speed of 30 min for 30 min to fully mix the two to obtain the product.

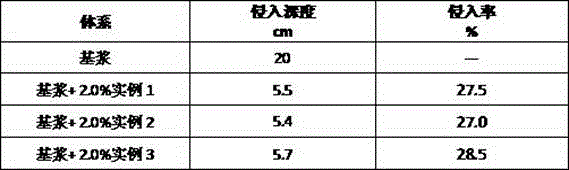

[0029]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com