A butter sealer

An occluder and butter technology, applied in the direction of pipes/pipe joints/pipes, mechanical equipment, pipe components, etc., can solve the problems of low work efficiency, high labor intensity, and loose sealing, and achieve easy operation and avoid corrosion damage. , The effect of not easy to leak oil and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

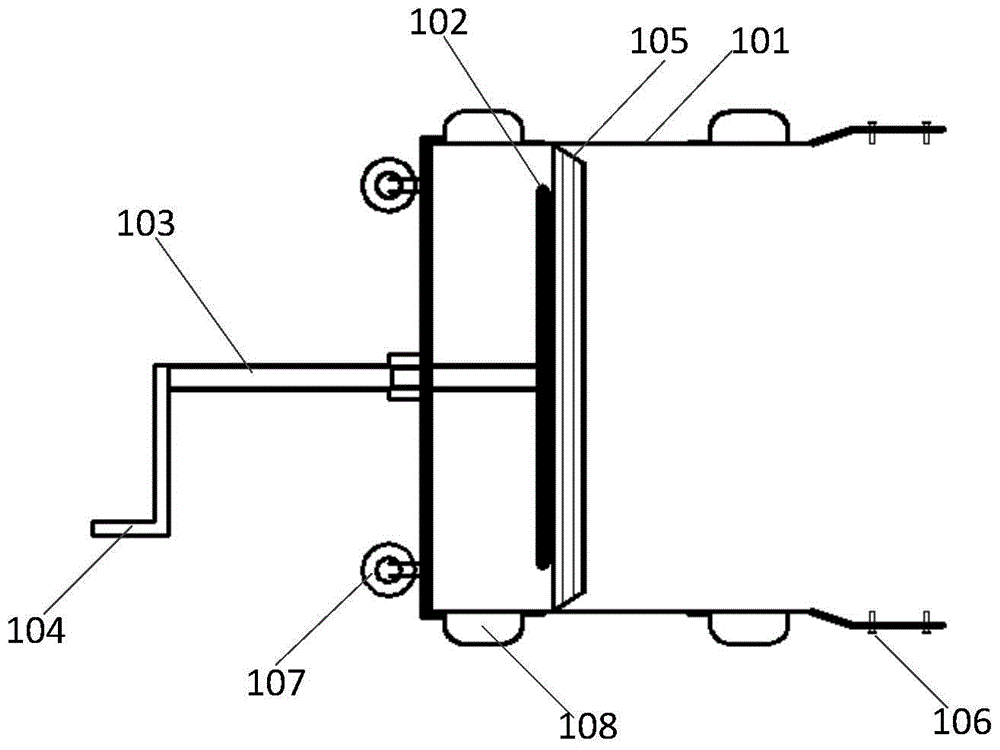

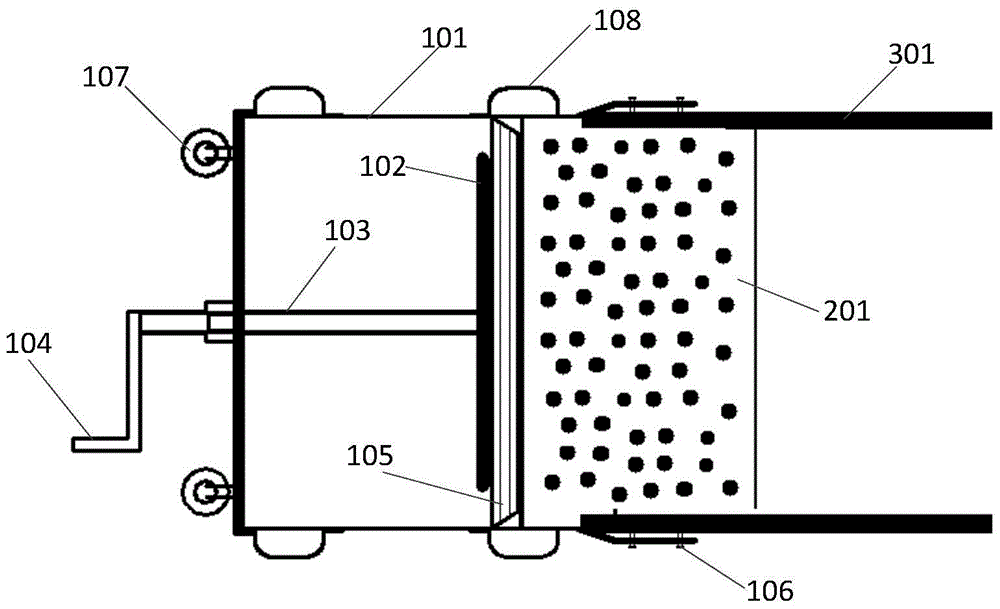

[0040] This embodiment provides a kind of butter occluder, such as figure 1 shown, including:

[0041] A metal barrel 101, the top of the metal barrel 101 is open, and a through hole is opened on the bottom plate of the metal barrel 101;

[0042] A steel push plate 102 is located in the metal barrel 101;

[0043] Screw mandrel 103, one end of screw mandrel 103 is connected with the lower end of steel propulsion plate 102, and the other end of screw mandrel 103 passes the through hole on the bottom plate of metal barrel 101 and is exposed to the outside of metal barrel 101;

[0044] The rocker arm 104 is connected with the other end of the screw rod 103 .

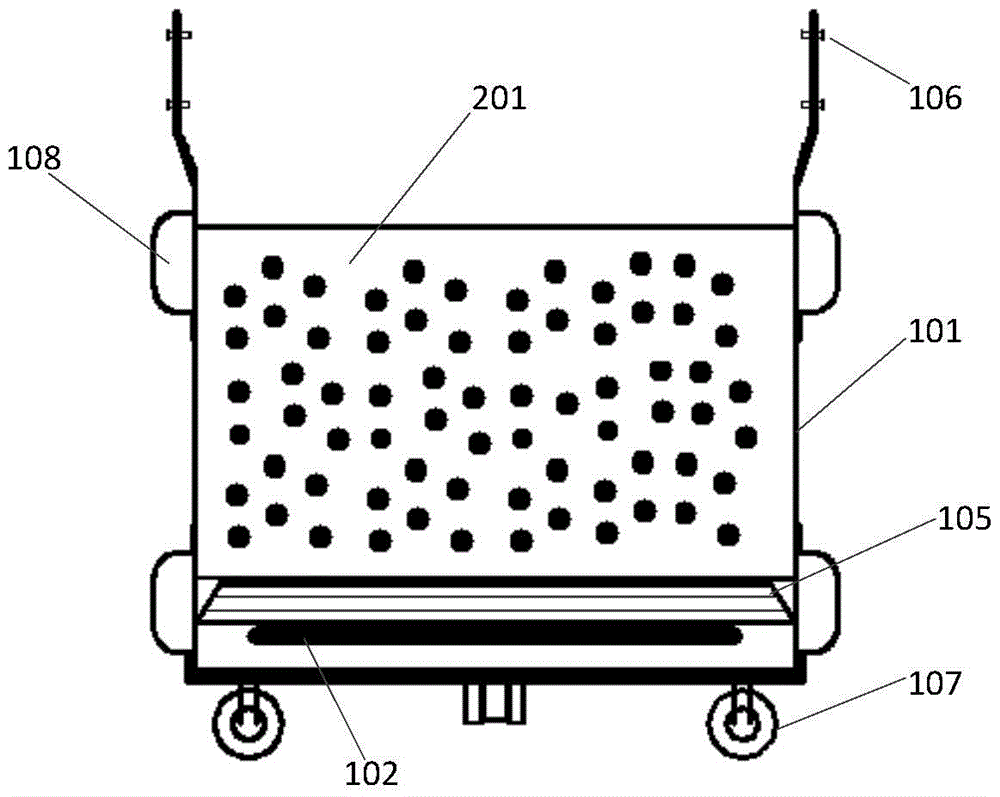

[0045] In the specific implementation process, the height of the metal barrel 101 is 600mm, the diameter is 720mm, and it is made of white steel plate with a thickness of 5mm. The metal barrel 101 is used to hold the mixed-molded butter wall 201, so as to obtain a once-molded, integrally-molded butter wall 201.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com