Device and method for detecting material

A material and product technology, applied in the field of material detection devices, can solve the problems of missing components, operators cannot quickly observe through eyes, etc., to reduce fatigue and ensure the effect of not being scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

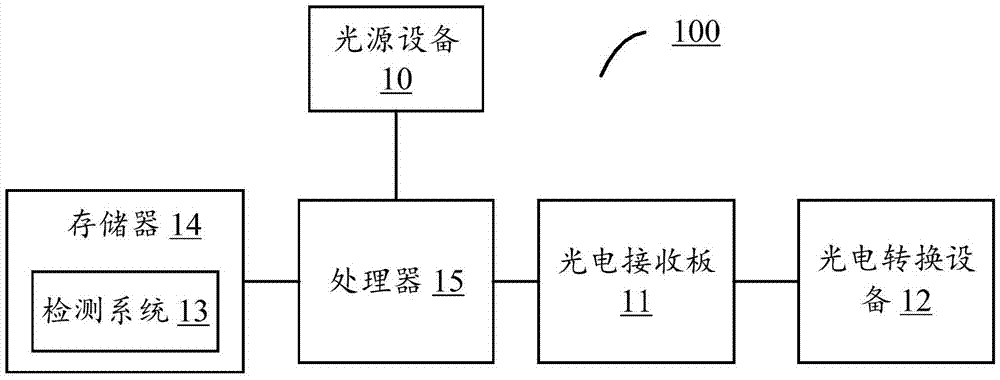

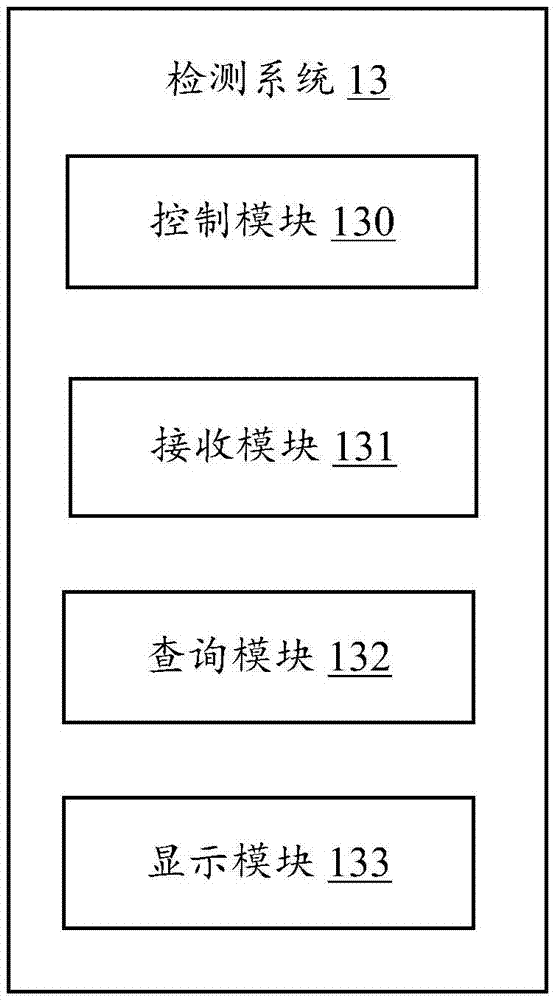

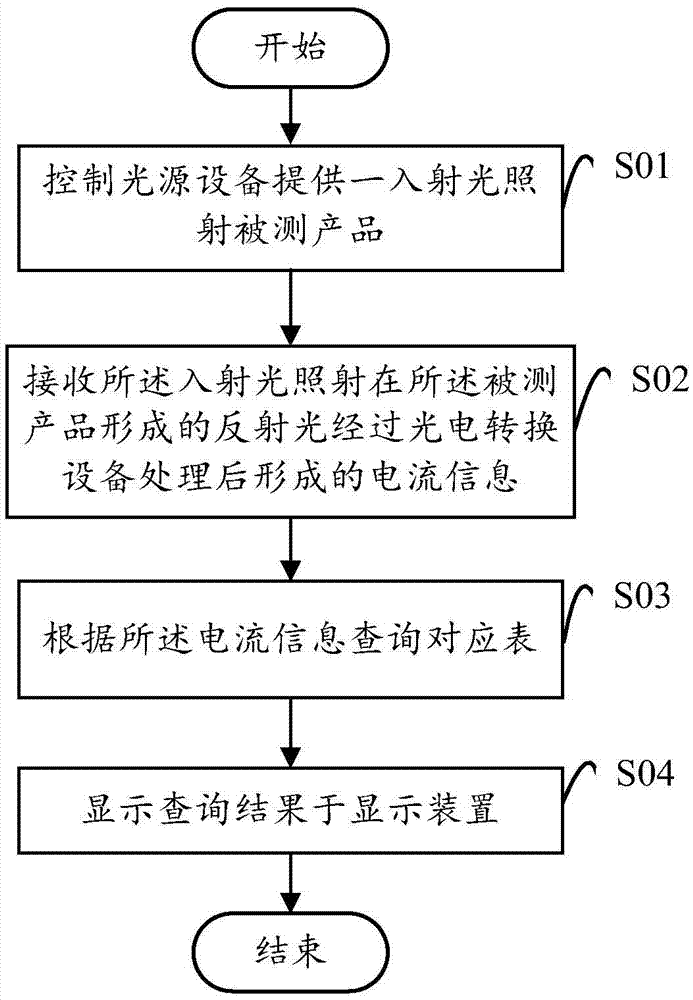

[0013] refer to figure 1 Shown is a device for detecting materials provided by a preferred embodiment of the present invention. The material detection device 1 includes, but not limited to, a light source device 10 , a photoelectric receiving board 11 , a photoelectric conversion device 12 , a detection system 13 , a memory 14 and a processor 15 that are electrically connected to each other.

[0014] In this embodiment, the light source device 10 is used to provide an incident light source, and the incident light source illuminates the product under test at a certain incident angle. In order to avoid total reflection of the incident light source, the incident angle ranges from greater than 0 degrees to less than 90 degrees. In this embodiment, the range of the incident angle is greater than 0 degrees and less than or equal to 80 degrees. The photoelectric receiving plate 11 is used for receiving the reflected light formed after the incident light irradiates the product under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com