Nonel tube detonator bayonet assembly quality detection device and method

A quality inspection method and technology of inspection devices, which are applied in measurement devices, material analysis by optical means, instruments, etc., can solve problems such as unqualified assembly quality, limited number of random inspections, and inability to fundamentally solve assembly quality problems. The effect of high production efficiency, improving production efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is:

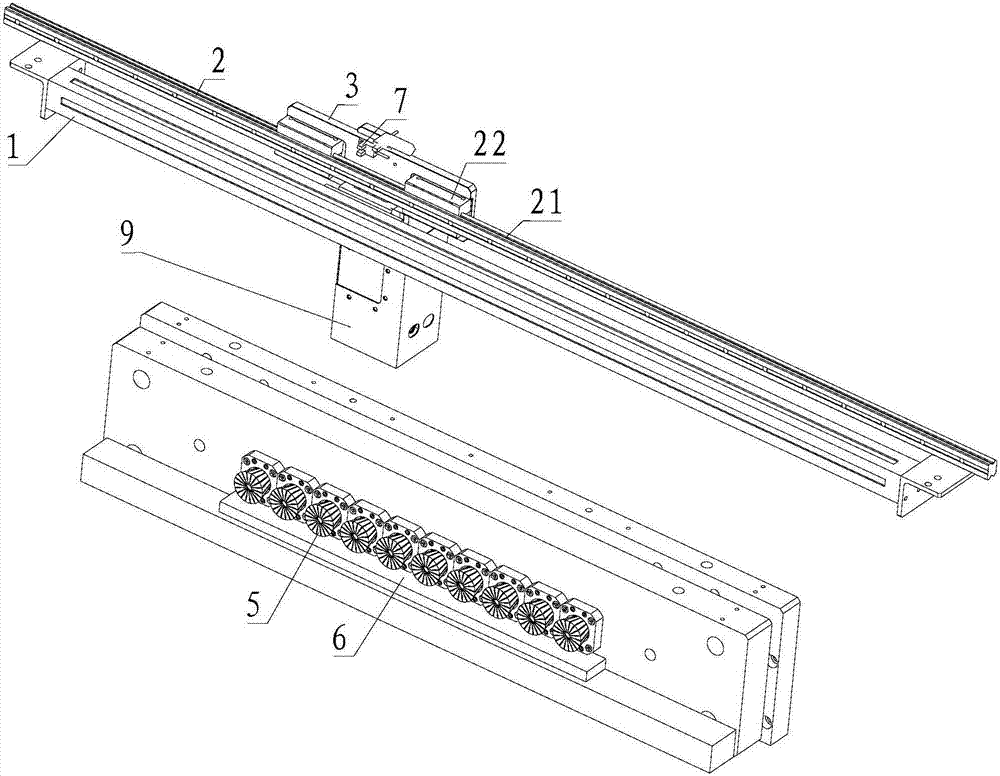

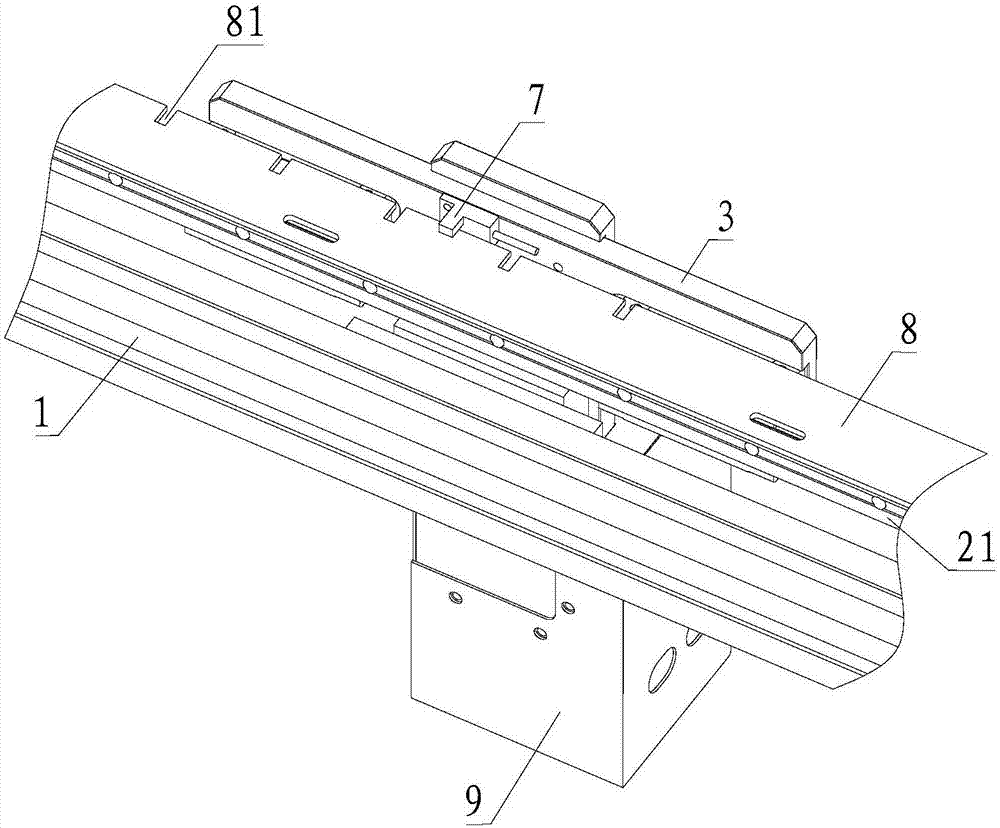

[0040] A nonel detonator bayonet assembly quality inspection device, comprising a moving power element 1, a moving guide element 2, a fixed frame 3, a visual camera 4, a bayonet fixture 5 and a lamp board 6, and the moving power element 1 passes through the The moving guide element 2 drives the fixed frame 3 to move linearly back and forth, the visual camera 4 is fixed on the fixed frame 3, and the lens of the visual camera 4 faces downward, and the number of the bayonet fixtures 5 is multiple, and horizontally arranged side by side, the lamp board 6 is located below a plurality of bayonet clamps 5, the length of the lamp board 6 is adapted to the total width of the multiple bayonet clamps 5, and the visual camera 4 Located above the bayonet fixture 5; preferably, the moving guide element 2 is a linear guide rail 21 and a slider 22 slidably connected to each other, the slider 22 is conn...

Embodiment 2

[0041] Please refer to Figure 1 to Figure 4 , the second embodiment of the present invention is:

[0042] A nonel detonator bayonet assembly quality detection device, on the basis of the first embodiment, also includes an infrared sensor 7 and a detection plate 8, the infrared sensor 7 is fixed on the back of the fixed frame 3, and the detection plate 8 are arranged horizontally, the height of the detection plate 8 is adapted to the height of the infrared sensor 7, and detection holes 81 are arranged on the detection plate 8, and the number of the detection holes 81 is the same as that of the bayonet fixture 5. The quantity is consistent.

Embodiment 3

[0043] Please refer to Figure 1 to Figure 4 , Embodiment three of the present invention is:

[0044] A nonel detonator bayonet assembly quality inspection device, on the basis of the first or second embodiment, also includes a camera shield 9, the camera shield 9 is covered outside the visual camera 4, and is fixed on the on the fixed frame 3.

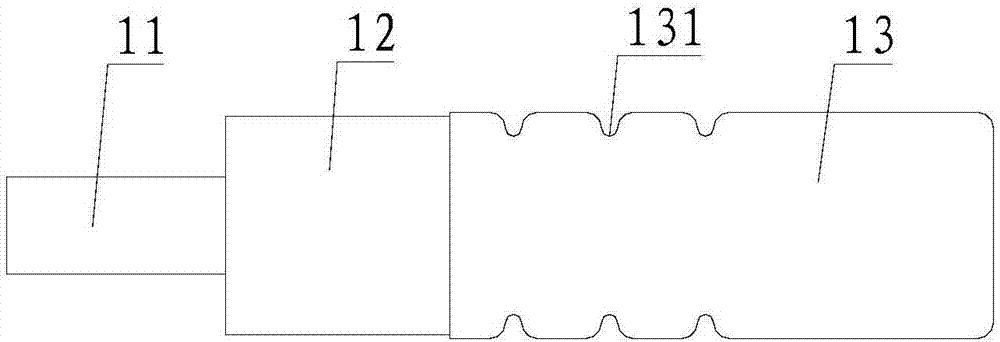

[0045] Please refer to Figure 5 to Figure 6 , a nonel detonator bayonet assembly quality inspection method, the ends of multiple nonel tubes 11 are covered with rubber plugs 12, the rubber plugs 12 are covered with basic detonators 13, the basic detonators 13 are installed in the bayonet fixture 5, clamped The holding mechanism clamps the detonator 11 and sends it into the basic detonator 13 equipped with a rubber plug 12. The bayonet fixture 5 applies pressure on the basic detonator 13 to press out the card mark 131, and connects the basic detonator 13 and the rubber plug 12 to the guide. The squib 11 is closely connected, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com