Linear light spot module

A line spot and module technology, applied in optics, instrumentation, photography, etc., can solve the problems of poor positioning accuracy, difficult adjustment of deviation angle, and affecting work efficiency, etc., achieving fast alignment, simple alignment steps, and accurate alignment high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

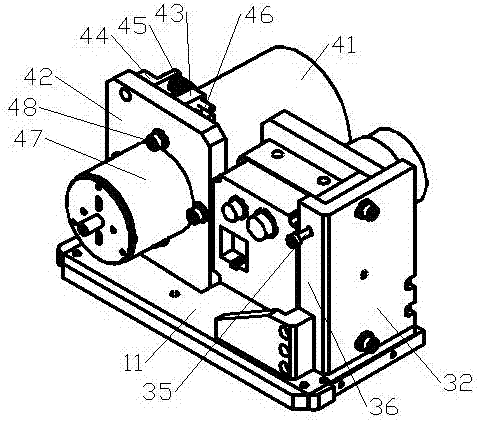

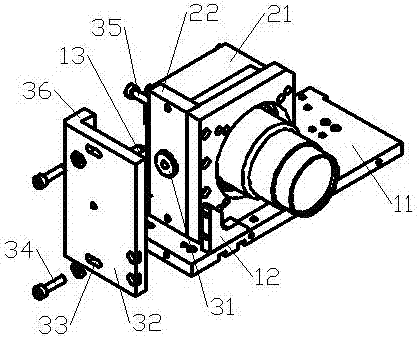

[0026] Such as Figure 1 to Figure 6 As shown, the line spot module includes a camera 21 and a laser light source 41, the camera 21 and the laser light source 41 are respectively located at the two ends of the base 11, the camera 21 is installed on the camera angle adjustment device, and the camera angle adjustment device is installed On the base 11 , the laser light source 41 is installed on a light source angle adjustment device, and the light source angle adjustment device is installed on the base 11 .

[0027] The camera angle adjustment device includes a side fixing plate 32 and an angle adjustment plate 36 all fixed on the base 11, a rotating shaft 31, a spring A37 and a limiting plate 35; the limiting plate 35 is fixed on the camera 21 away from the laser light source. On one side of 41, the limiting plate 35 is provided with shaft holes and threaded holes; the side fixing plate 32 is located on one side of the limiting plate 35, and the side fixing plate 32 is provided...

Embodiment 2

[0033] On the basis of the above examples, if Figure 1 to Figure 5 As shown, the angle adjusting plate 36 is fixed on the base 11 through the rear fixing plate 13, the side fixing plate 32 is fixed on the base 11 through the front fixing plate 12, and the angle adjusting plate 36 and the side fixing plate 32 are integral structure, forming an L shape.

[0034] The side fixing plate 32 and the angle adjusting plate 36 are made into an integral structure with good strength and easy assembly.

[0035] Front fixed plate 12 and rear fixed plate 13 improve stability.

Embodiment 3

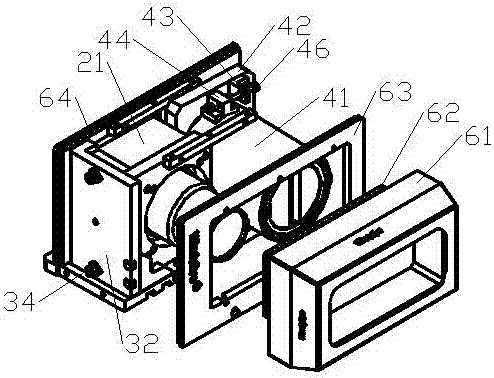

[0037] On the basis of the above examples, if figure 1 and Figure 7 As shown, it also includes a window cover 61, a panel 63, a cover 65 and a rear cover 64, the panel 63 and the rear cover 64 are respectively fixed on both sides of the base 11, and the cover 65 is fixed on the panel 63 and the rear Between the cover plates 64, the window cover 61 is fixed on the panel 63, the camera 21 and the laser light source 41 are located inside the window cover 61, and the window cover 61 is equipped with a light-transmitting protective sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com