A dust-proof heat dissipation box for a chassis

A heat dissipation box and chassis technology, which is applied in the computer field, can solve the problems of poor heat dissipation and dustproof effect of the chassis, and achieve the effect of novel and unique structure and solve the heat dissipation problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

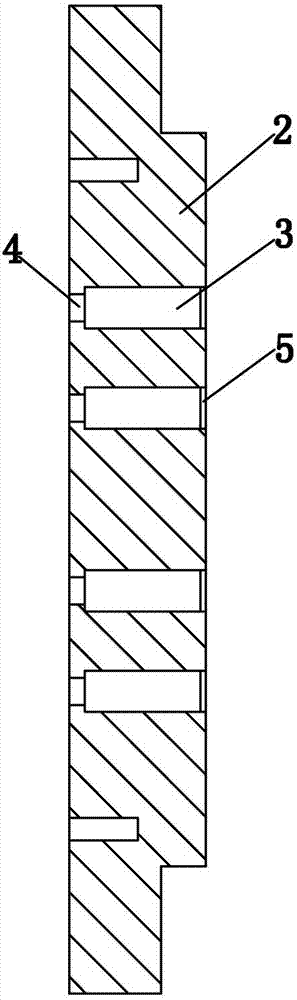

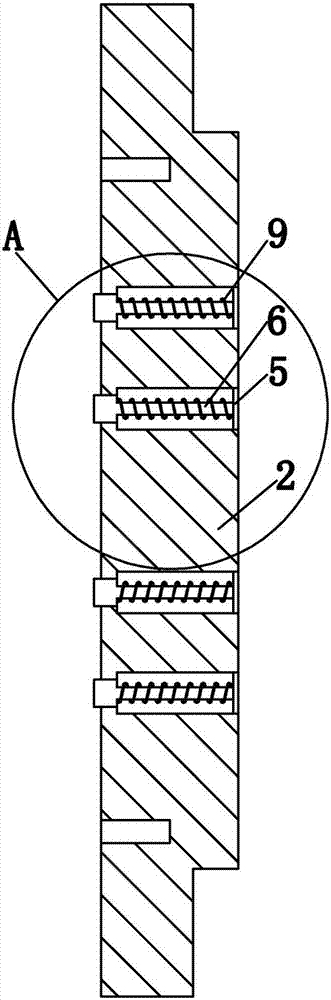

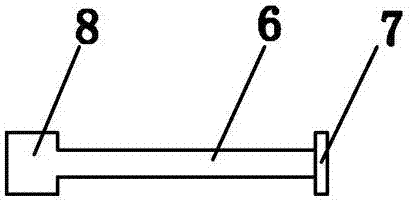

[0019] Depend on Figure 1 to Figure 11 Given, the present invention comprises base plate 1, and base plate 1 is equipped with air-permeable plate 2, and air-permeable plate 2 is a circular plate, and first through-hole 3 is arranged on the air-permeable plate, and the left side of first through-hole 3 has and the first through-hole 3 The concentric and connected second through hole 4, the diameter of the first through hole 3 is larger than the diameter of the second through hole 4, the first through hole 3 and the second through hole 4 pass through the air-permeable plate 2, the right port of the first through hole 3 There is a baffle plate 5 with air vents on the baffle plate 5, an air inlet channel 10 corresponding to the air vent holes on the bottom plate 1, a push rod 6 that can move left and right is inserted on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com