Safe battery pack shunt circuit structure

A circuit structure and battery pack technology, which is applied to battery circuit devices, circuits, secondary batteries, etc., can solve problems such as paralysis, fire circuits, and user safety hazards, and achieve the effects of preventing spontaneous combustion, protecting batteries, and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

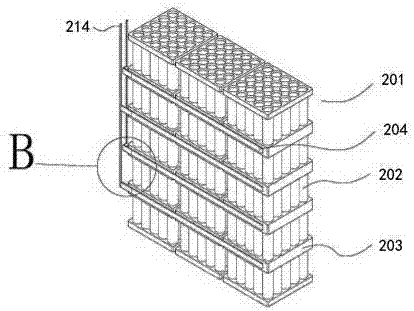

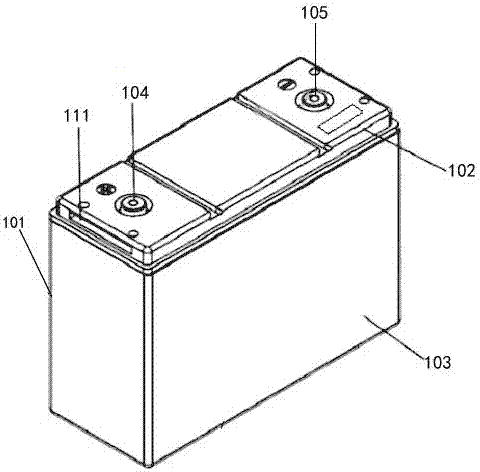

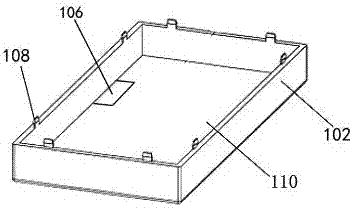

[0028] Such as Figures 1 to 10 As shown in one of them, the present invention includes a battery pack 201, the battery pack 201 includes a battery 202, a polypropylene connecting plate 203 for fixing the battery 202 and a PCB board 204 electrically connecting the batteries 202 to each other, the connecting plate 203 is provided with a The fixed through holes 205 for fixing the battery 202 are arranged in an array, and a circular conductive sheet 206 is arranged in the middle of the fixed through hole 205. The conductive sheets 206 in the same row in the fixed through holes 205 are electrically connected to each other, and extend from one end. part 207 and attached to the side of the connecting plate 203 , the attaching position of the connecting plate 203 corresponding to the extension part 207 is provided with a second groove 211 and a concave structure 212 adapted to the connecting line between the corresponding conductive sheets 206 .

[0029] The same electrode of the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com