Non-water injection type pulping equipment for pulping based on state change

A technology of physical state change and pulping, applied in textile and papermaking, raw material separation, fiber raw material processing, etc., can solve the problems of low pulp quality, low crushing rate, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

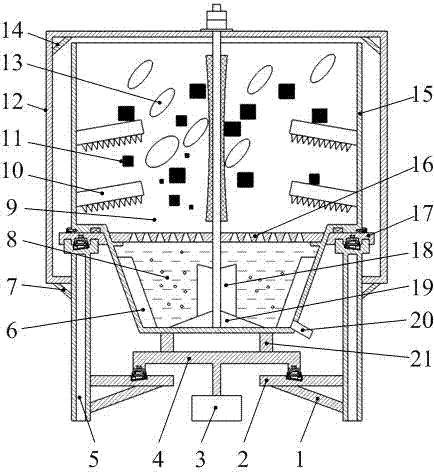

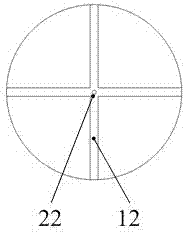

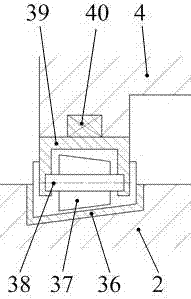

[0041] Such as figure 1 As shown, a kind of water-injection pulping equipment based on physical state change pulping of the present invention mainly includes a supporting device, a driving rotating device, an auxiliary rotating device, a crushing device 9 and a stirring device 8, a driving rotating device and an auxiliary rotating device Installed on the supporting device sequentially from bottom to top, the crushing device 9 is installed above the stirring device 8, the crushing device 9 is installed above the auxiliary rotating device, and the stirring device 8 is installed above the driving rotating device.

[0042] In the present invention, the pulping process is realized through the two links of the crushing device 9 and the stirring device 8. Through this design, water-injection-free pulping is realized, that is, the crushing of the large fragments 13 is realized through the crushing device 9, and the result of the stirring device 8 is generated. The required water 26 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com