A Municipal Management Tram Lawn Automatic Cleaning and Harvesting Compression Packaging Machine

A tram and automatic cleaning technology, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of motor combustion, passenger safety, and low pruning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

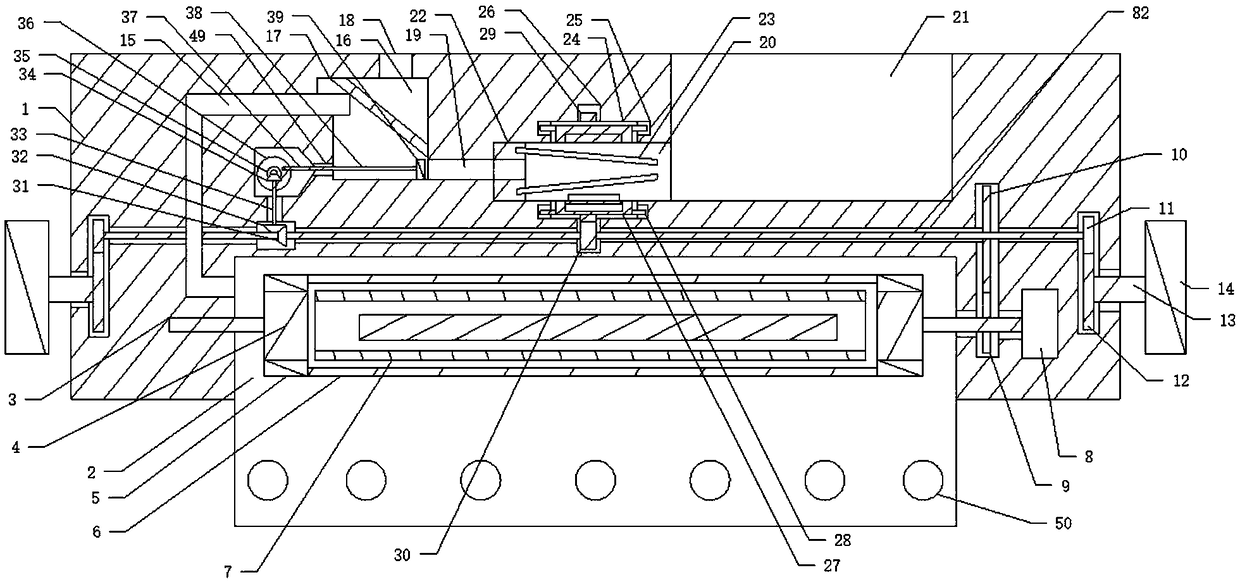

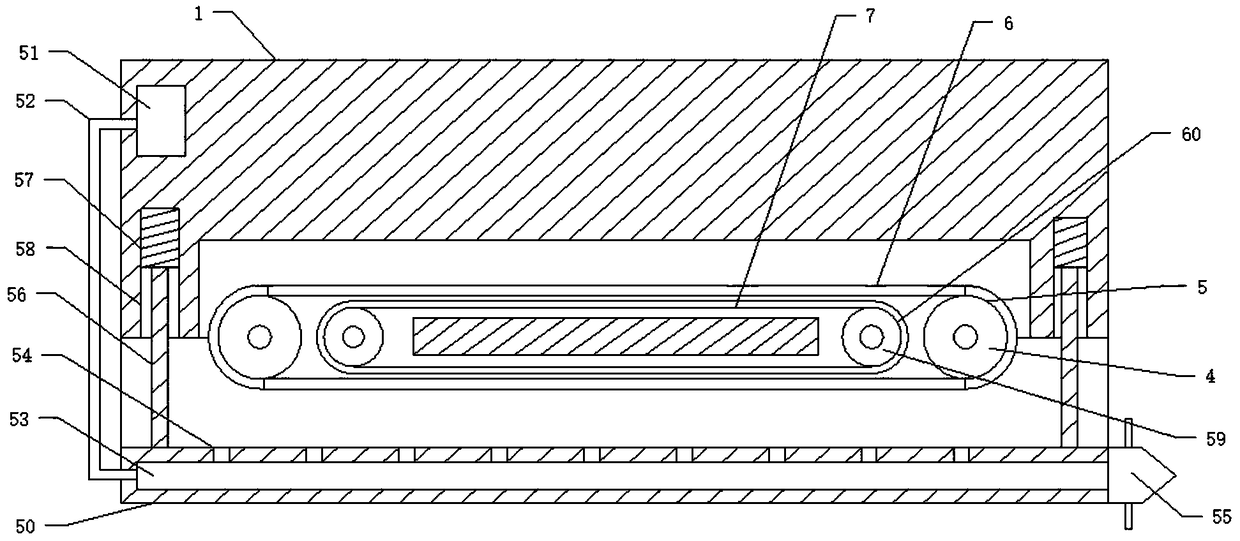

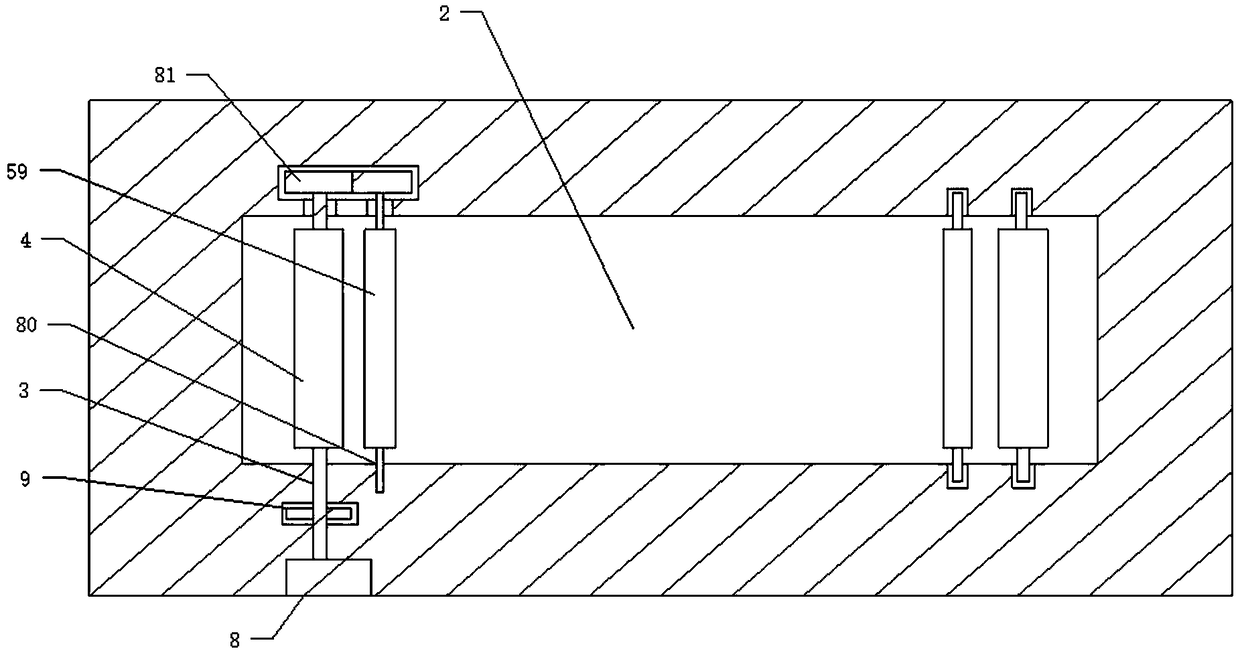

[0039] Such as Figure 1 to Figure 9As shown, a municipal management tram lawn automatic cleaning harvesting compression packaging machine includes a body 1, two rotating track wheels 14 are respectively provided on both sides of the body 1, and a harvesting groove is also provided at the bottom of the body 1 2. A correspondingly rotating first chain 5 and a second chain 60 are arranged in the harvesting trough 2, and a first cutting knife bar 6 and a first cutting knife bar 6 are respectively connected side by side on the first chain 5 and the second chain 60. A second cutting knife bar 7, the first cutting knife bar 6 is correspondingly connected with the second cutting knife bar 7, and a rotating track wheel 14 is respectively arranged on both sides of the body 1, so that the The track wheel 14 rotates on the track, so that the body 1 can be further slid on the track, and a harvesting groove 2 is arranged at the bottom of the body 1, and the harvesting groove 2 is a groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com