Woven belt continuous conveying device

A technology of conveying device and braided belt, which is applied in the directions of transportation packaging, transportation and packaging, and packaging material feeding device, etc., which can solve problems such as difficult manipulator grasping and affecting the packaging efficiency of braided belts, reduce labor intensity and improve outer packaging Effect, long-term use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

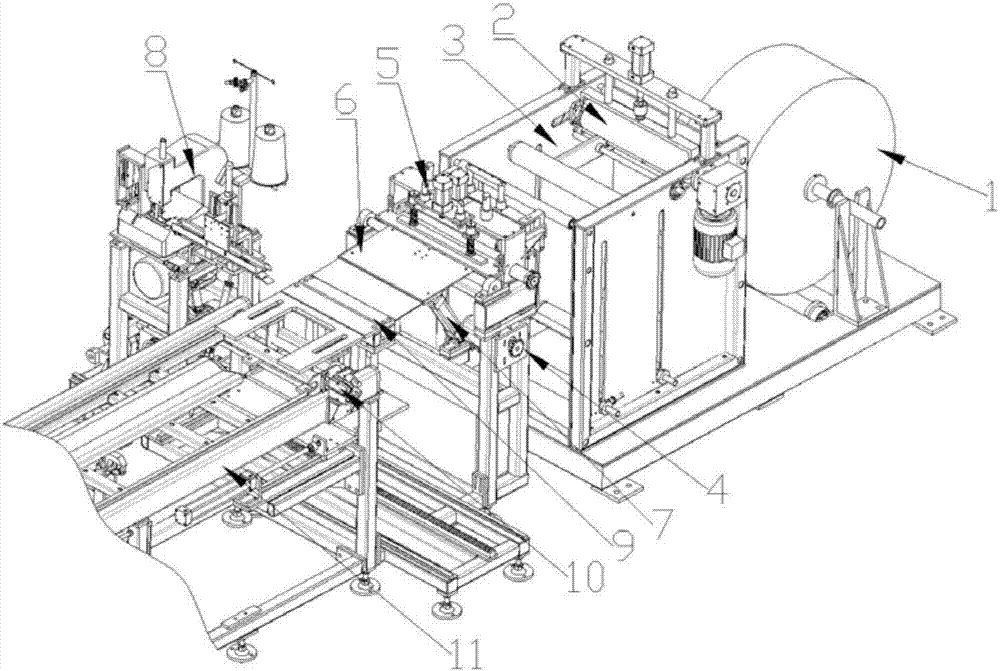

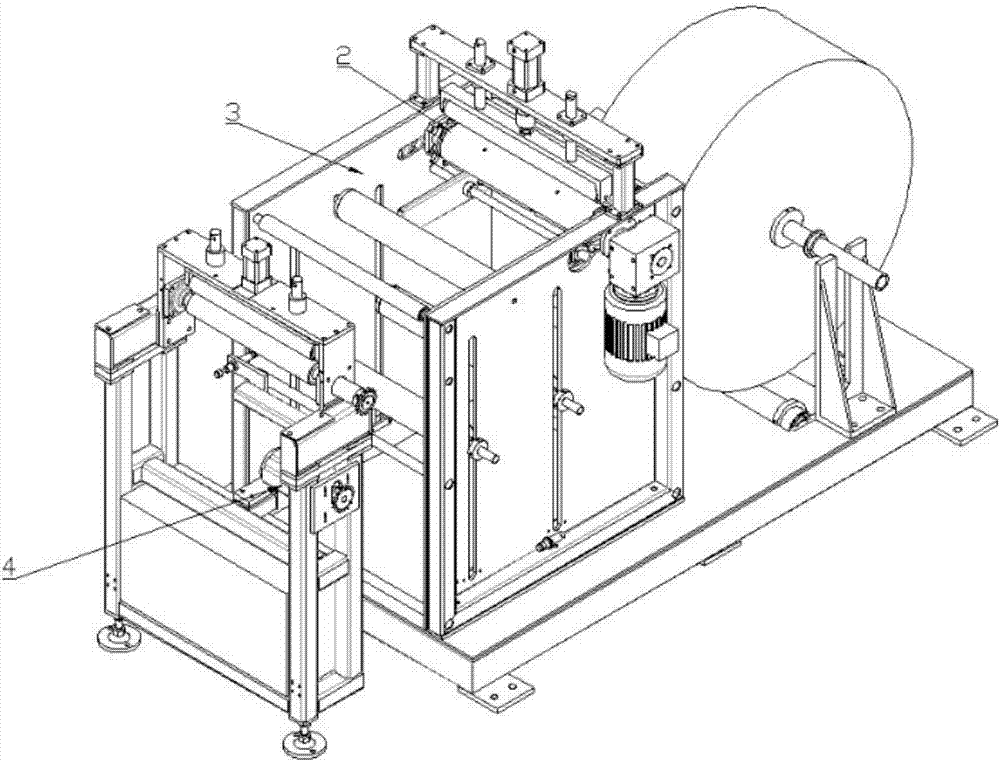

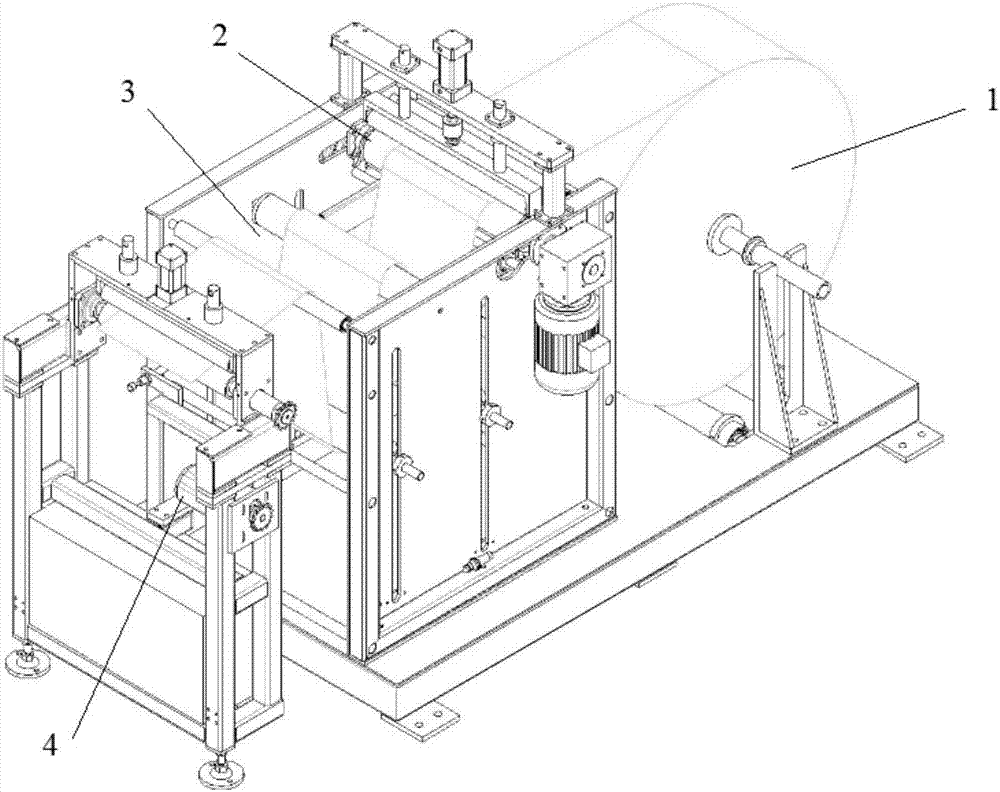

[0026] A kind of braided belt continuous conveying device, its structure is as figure 1 As shown, it includes a braided tape material roll 1, a tape unwinding mechanism, a cutter 5, a material receiving platform plate 9 and a manipulator 10 arranged sequentially along the braided tape conveying path. In order to pull out and drive the braided belt forward, the manipulator 10 is used to grab the braided tape head conveyed by the receiving platform plate 9 and send it to the subsequent packaging area. It also includes a movable automatic sealing mechanism 8 and a liftable Bridge the flap 6, the lower end of the bridge flap 6 is connected to a fixed lift cylinder 7, and the lifting action of the lift cylinder 7 drives the bridge flap 6 to lift or fall. Automatic sealing mechanism 8 is used for the automatic sealing mechanism 8 of the braided belt sealing after cutting, comprises moving guide rail and automatic sealing assembly, and moving guide rail is arranged on the below of br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com