A kind of ag/tio2/zno nanowire with core-shell structure and preparation method thereof

A technology of core-shell structure and nanowires, which is applied in the field of core-shell structure Ag/TiO2/ZnO nanowires and its preparation, can solve the problems of no Ag/TiO, etc., and achieve the effect of improving stability and carrier separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

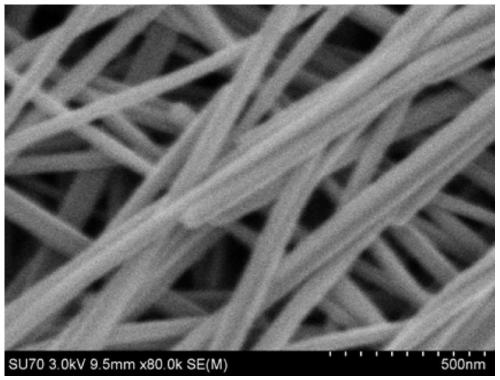

[0027] 1) Preparation of Ag nanowires: add 2.93g polyvinylpyrrolidone to 95mL glycerol, stir for 1.5h at 90℃, then stop heating, cool to 50℃, add 0.79g silver nitrate; prepare 29.5mg chlorinated A mixed solution of sodium, 0.25mL deionized water, 5mL glycerol, then add the mixed solution to the container, and then heat to 210℃, react for a total of 40min, stop heating, take out, wash and separate to obtain a diameter of 50-100nm and a length of tens of microns Silver nanowires.

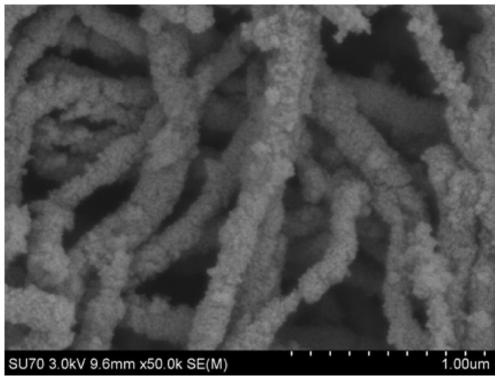

[0028] 2) Disperse 100mg silver nanowires in 40mL ethanol solution, then add 8mg polyvinylpyrrolidone, magnetically stir for 10min, then add 0.4mL tetrabutyl titanate and 0.6mL deionized water dropwise, continue stirring for 30min, deionize Wash with water, disperse in 10mL deionized water, hydrothermally react at 160℃ for 12h to obtain core-shell Ag / TiO 2 Nanowires.

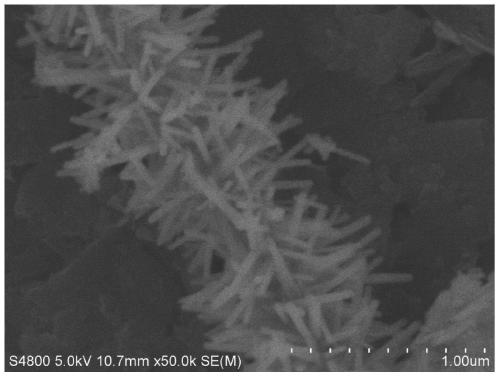

[0029] 3) Add 68.5 mg of zinc acetate to 32 mL of methanol, stir at 60°C for 40 min, then add 16.5 mL of methanol solution containing 27.5...

Embodiment 2

[0033] 1) Same as step (1) of Example 1.

[0034] 2) Disperse 100mg silver nanowires in 40mL ethanol solution, then add 8mg polyvinylpyrrolidone, magnetically stir for 10min, then add 0.4mL tetrabutyl titanate and 0.6mL deionized water dropwise, continue stirring for 30min, deionize Wash with water, disperse in 10mL deionized water, hydrothermally react at 120℃ for 12h to obtain core-shell Ag / TiO 2 Nanowires.

[0035] 3) Same as step (3) of Example 1.

[0036] 4) Transfer the product obtained in step 3) to 30mL aqueous solution containing 0.178g zinc nitrate and 0.084g hexamethylenetetramine, stir and react at 80℃ for 1 h to obtain core-shell Ag / TiO 2 / ZnO nanowires.

[0037] Image 6 The field emission scanning electron microscopy photographs show that Ag / TiO was successfully obtained 2 / ZnO one-dimensional core-shell branched nanowire structure.

Embodiment 3

[0039] 1) Same as step (1) of Example 1.

[0040] 2) Disperse 100mg silver nanowires in 40mL ethanol solution, then add 8mg polyvinylpyrrolidone and magnetically stir for 10min, then add 0.4mL tetrabutyl titanate and 0.6mL deionized water drop by drop, continue stirring for 30min, use deionized water Wash, disperse in 10mL deionized water, hydrothermally react at 200℃ for 8h to obtain core-shell Ag / TiO 2 Nanowires.

[0041] 3) Same as step (3) of Example 1.

[0042] 4) Transfer the product obtained in step 3) to 30mL aqueous solution containing 0.178g zinc nitrate and 0.084g hexamethylenetetramine, and stir for 2h at 90℃ to obtain core-shell Ag / TiO 2 / ZnO nanowires.

[0043] Figure 7 The field emission scanning electron microscopy photographs show that Ag / TiO was successfully obtained 2 / ZnO one-dimensional core-shell branched nanowire structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com