A mixing device for the production of lime fly ash soil subbase of traffic road

A mixing device and sub-base technology, which is applied to clay preparation devices, sales raw material supply devices, cement mixing devices, etc., can solve the problems of low mixing efficiency and separate addition of raw materials, and achieve high-efficiency mixing and stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

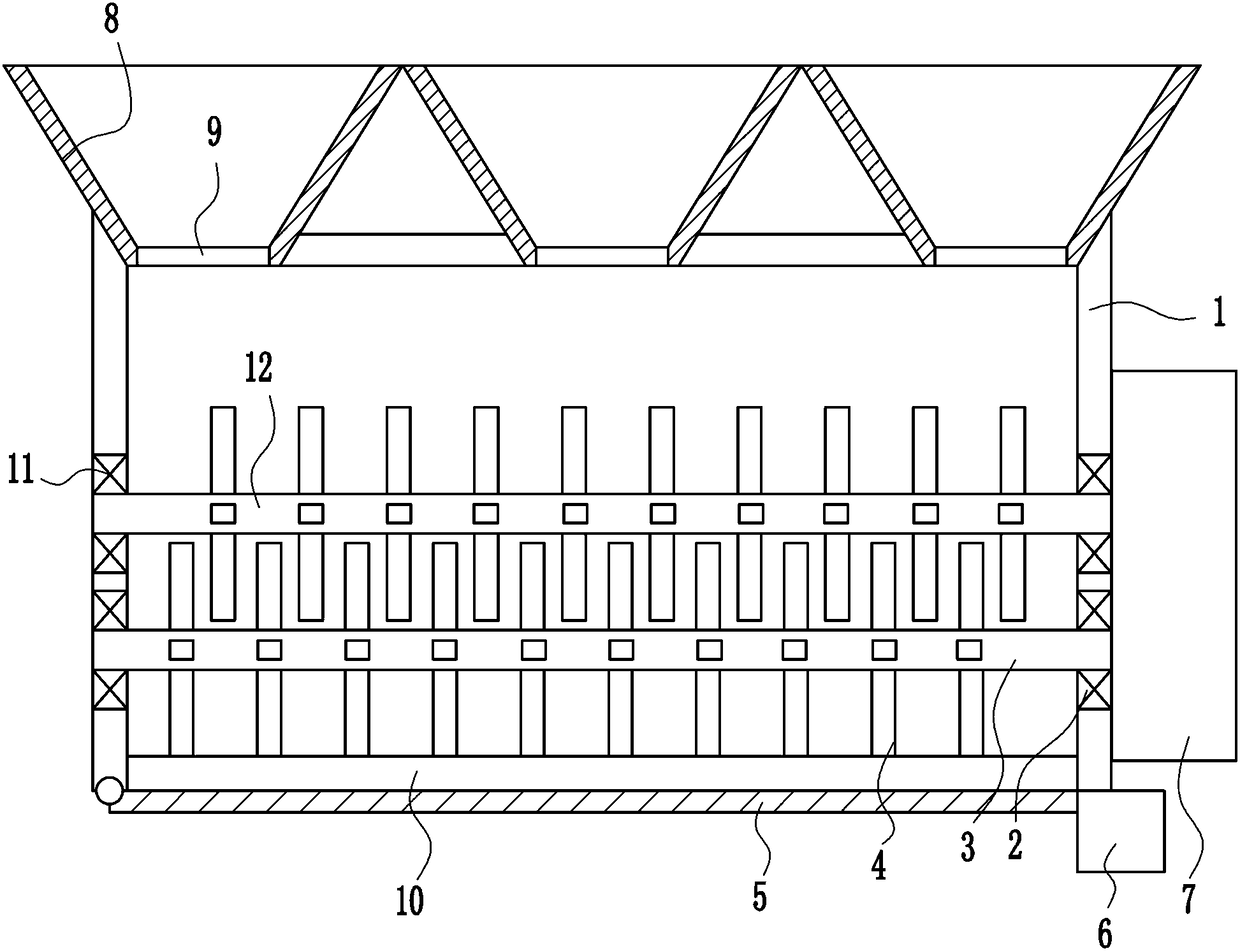

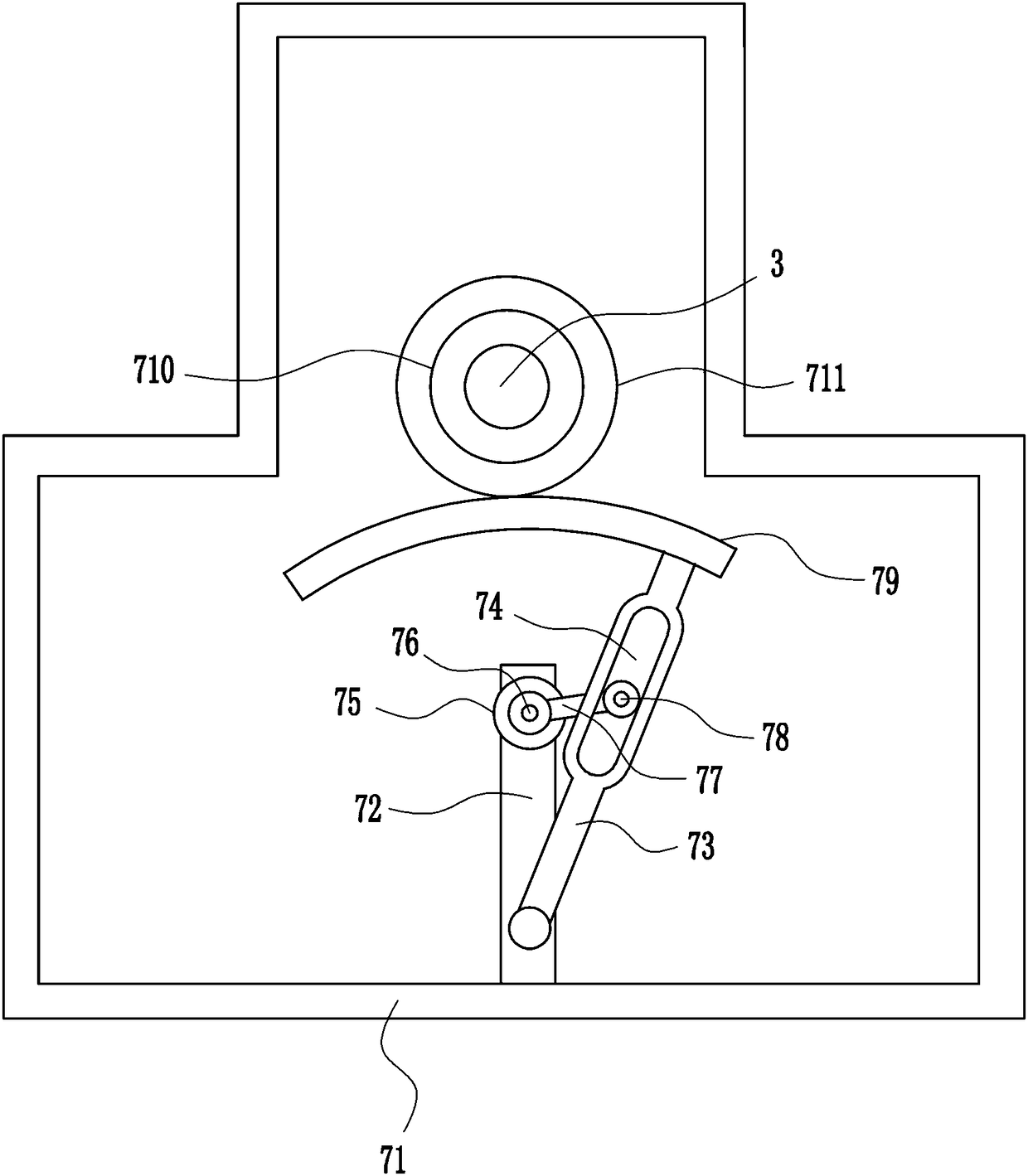

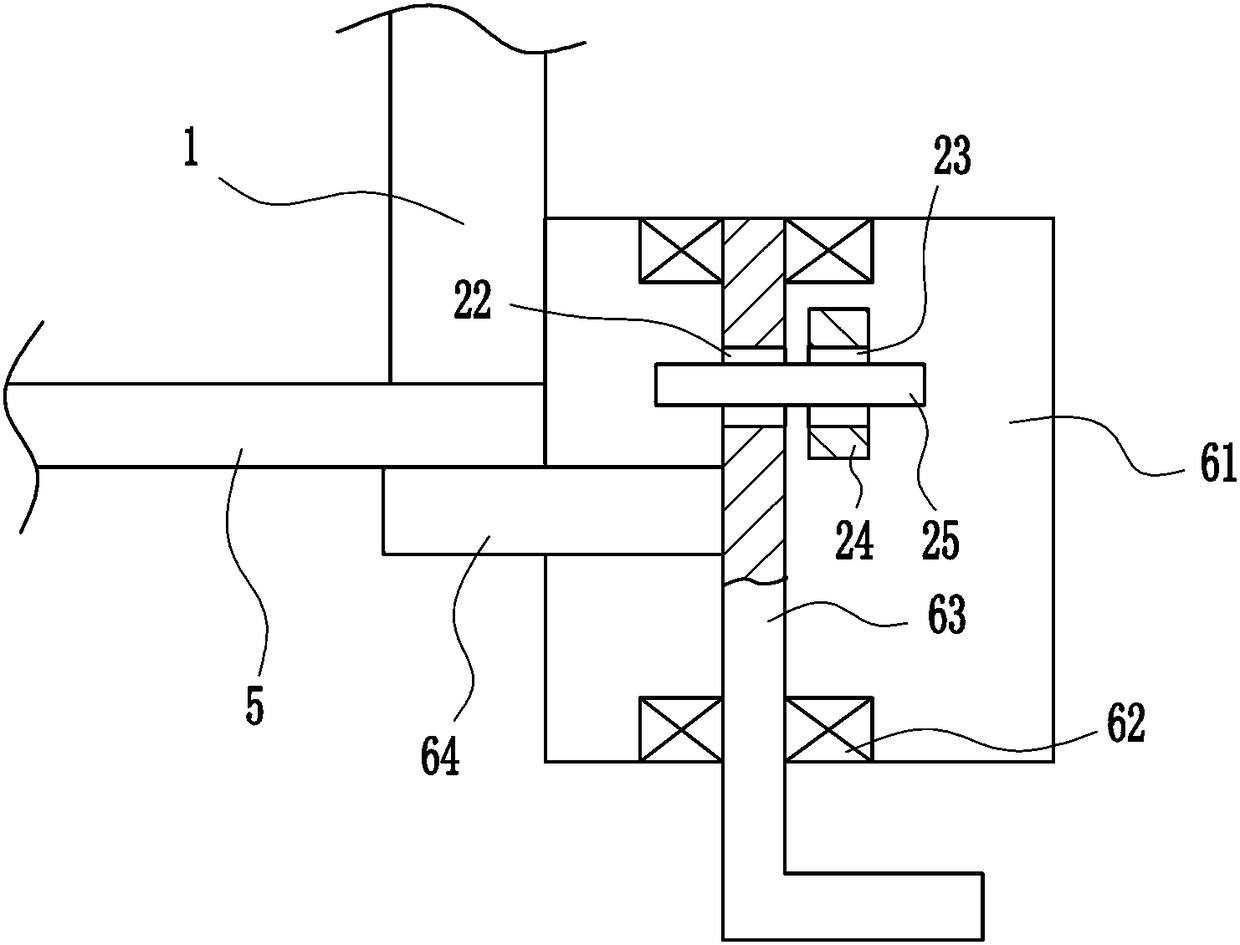

[0041] A mixing device for the production of traffic road lime fly ash soil subbase, such as Figure 1-8 As shown, it includes a mixing box 1, a first bearing seat 2, a first rotating rod 3, a stirring rod 4, a first baffle plate 5, a fixing mechanism 6, a driving mechanism 7 and a feeding hopper 8, and the bottom left and right sides of the mixing box 1 The first bearing seat 2 is installed on both sides, the first bearing seat 2 is connected with the first rotating rod 3, the first rotating rod 3 is evenly connected with the stirring rod 4, and the left bottom of the mixing box 1 is rotationally connected with the second A baffle plate 5, the right bottom of the mixing box 1 is connected with a fixing mechanism 6, the outer right side of the mixing box 1 is connected with a driving mechanism 7, the top of the mixing box 1 is evenly connected with a feed hopper 8, and the bottom of the feed hopper 8 is connected to the The top of the mixing box 1 is uniformly opened with a fi...

Embodiment 2

[0043] A mixing device for the production of traffic road lime fly ash soil subbase, such as Figure 1-8 As shown, it includes a mixing box 1, a first bearing seat 2, a first rotating rod 3, a stirring rod 4, a first baffle plate 5, a fixing mechanism 6, a driving mechanism 7 and a feeding hopper 8, and the bottom left and right sides of the mixing box 1 The first bearing seat 2 is installed on both sides, the first bearing seat 2 is connected with the first rotating rod 3, the first rotating rod 3 is evenly connected with the stirring rod 4, and the left bottom of the mixing box 1 is rotationally connected with the second A baffle plate 5, the right bottom of the mixing box 1 is connected with a fixing mechanism 6, the outer right side of the mixing box 1 is connected with a driving mechanism 7, the top of the mixing box 1 is evenly connected with a feed hopper 8, and the bottom of the feed hopper 8 is connected to the The top of the mixing box 1 is uniformly opened with a fi...

Embodiment 3

[0046] A mixing device for the production of traffic road lime fly ash soil subbase, such as Figure 1-8 As shown, it includes a mixing box 1, a first bearing seat 2, a first rotating rod 3, a stirring rod 4, a first baffle plate 5, a fixing mechanism 6, a driving mechanism 7 and a feeding hopper 8, and the bottom left and right sides of the mixing box 1 The first bearing seat 2 is installed on both sides, the first bearing seat 2 is connected with the first rotating rod 3, the first rotating rod 3 is evenly connected with the stirring rod 4, and the left bottom of the mixing box 1 is rotationally connected with the second A baffle plate 5, the right bottom of the mixing box 1 is connected with a fixing mechanism 6, the outer right side of the mixing box 1 is connected with a driving mechanism 7, the top of the mixing box 1 is evenly connected with a feed hopper 8, and the bottom of the feed hopper 8 is connected to the The top of the mixing box 1 is uniformly opened with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com