A kind of wrapping assembly of window glass

A vehicle window glass and assembly technology, applied in windshields, windows, vehicle parts, etc., can solve problems such as unfavorable installation and maintenance, unfavorable production efficiency, and differences in fixing and positioning peripheral parts matching, so as to improve the appearance and Sealing effect, improving the overall assembly effect, solving the effect of water leakage and wind noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

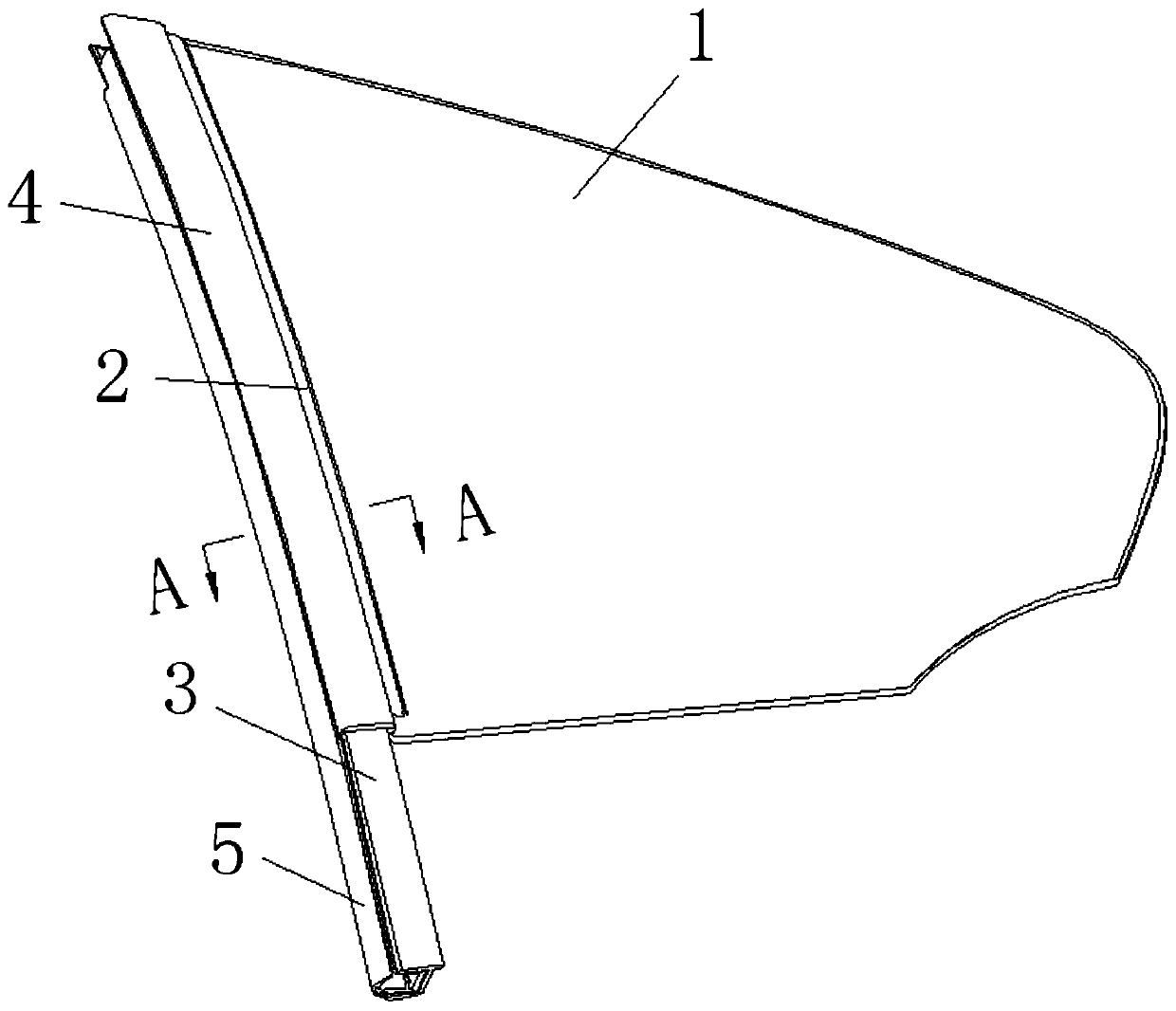

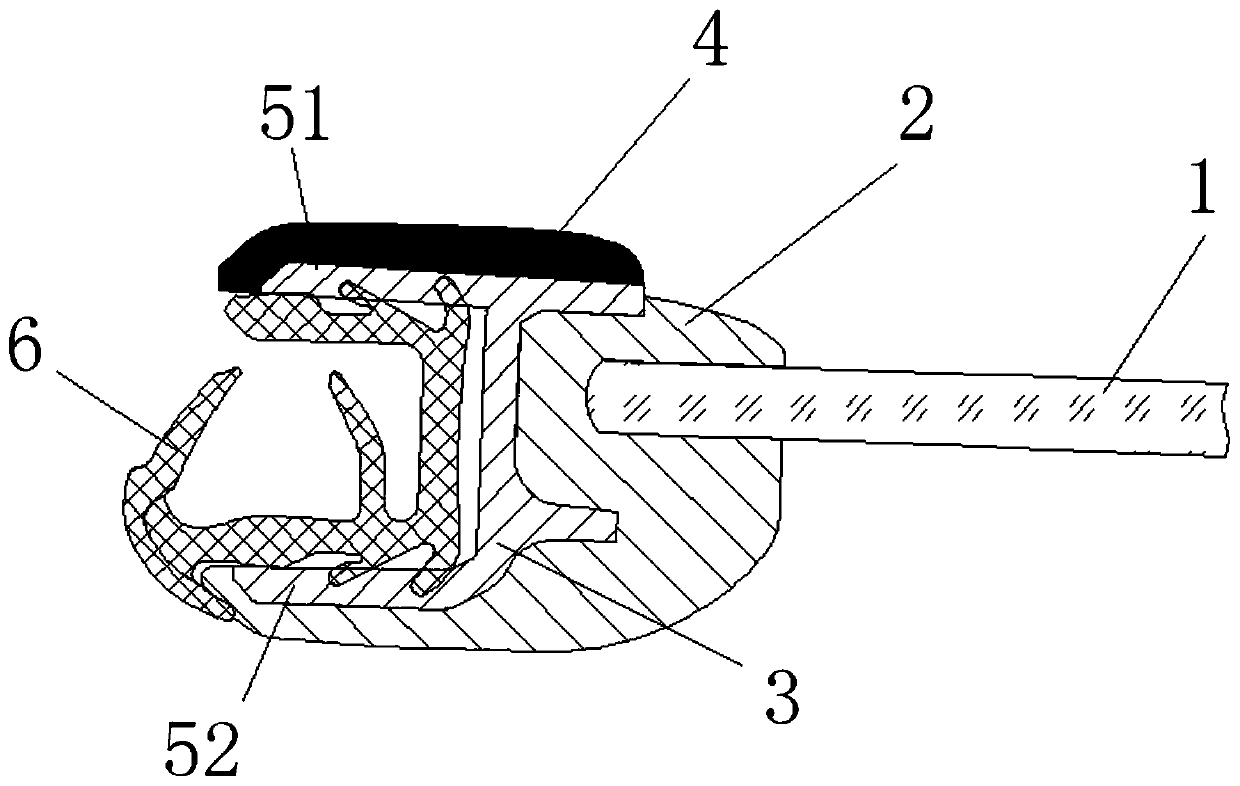

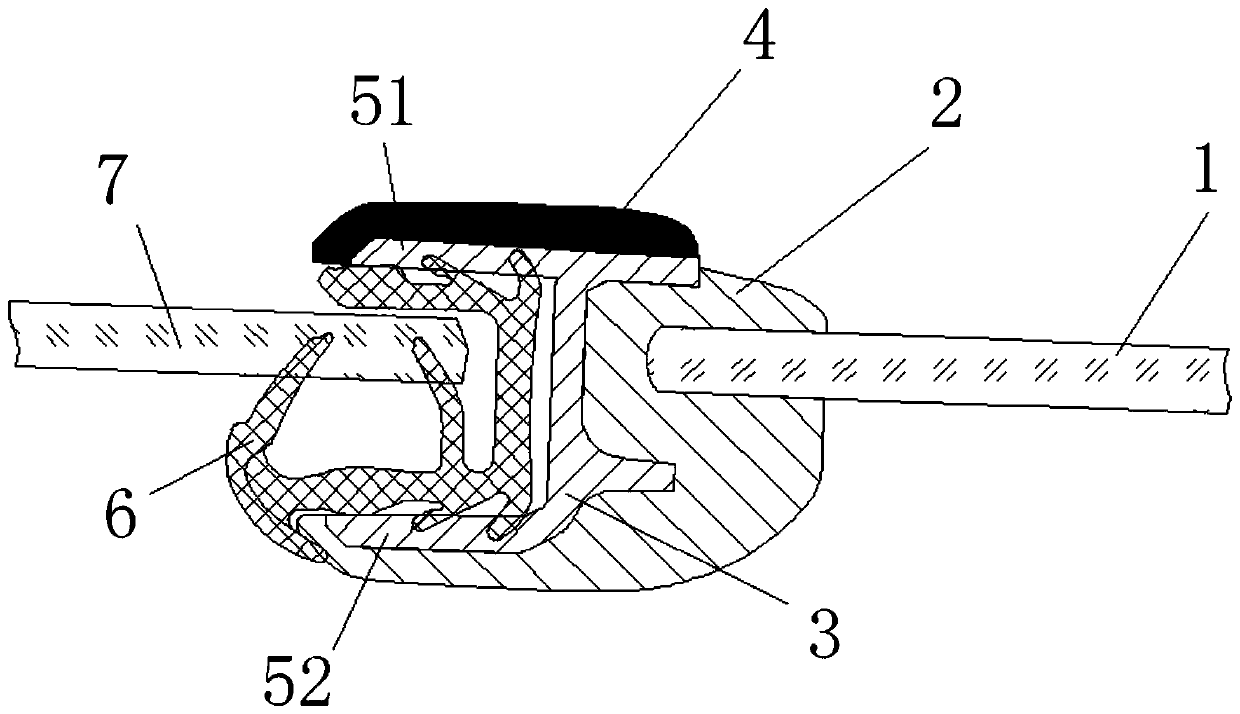

[0024] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 1~4 As shown, a kind of wrapping assembly of vehicle window glass according to the present invention includes a first glass 1, wrapping 2, plastic guide rail 3, sealing strip 6 and decorative layer 4, and the inside of the plastic guide rail 3 is used for sliding To connect the second glass 7, it is characterized in that: one end of the plastic guide rail 3 is fixedly connected to the edge of the first glass 1 through integral injection molding of the wrapping 2, and the other end of the plastic guide rail 3 is provided with a guide for guiding The guide groove 5 through which the second glass 7 slides, the guide groove 5 includes an upper side wall 51 and a lower side wall 52 opposite to each other, and a sealing strip 6 is fixed between the upper side wall 51 and the lower side wall 52, so The second glass 7 is slidingly matched...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com