Plane multi-cavity sectional material capable of improving overall structural strength

A technology of overall structure and body profiles, applied in building components, building structures, windows/doors, etc., can solve the problems of insufficient design of profile bodies, poor sound insulation effect of profile bodies, and insufficient strength of profile bodies, etc., to meet the requirements of use , improve the effect of sound insulation and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be described below in conjunction with specific embodiments.

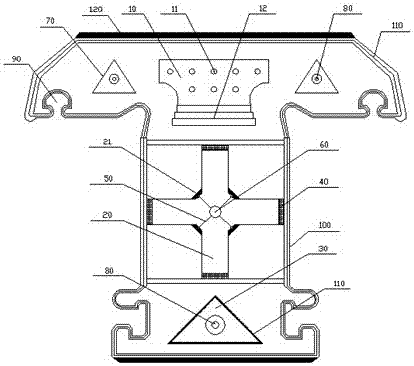

[0015] Such as figure 1 As shown, it is a schematic structural diagram of a planar multi-cavity profile that improves the overall structural strength of the present invention, including: a profile body 100, and an aluminum alloy steel sheet 110 is implanted around the frame of the profile body 100 by hot melting technology, so that The profile body 100 is sequentially provided with an upper cavity 10, a middle cavity 20 and a lower cavity 30 from top to bottom, the upper cavity 10 is an irregular cavity, and the middle cavity 20 is a cross cavity, so The lower cavity 30 is a triangular cavity;

[0016] The connection between the cross cavity body 20 and the profile body 100 is provided with a reinforcement layer 40, and the four corners inside the cross cavity body 20 are all processed into a wedge structure 21, and the middle part of each wedge structure 21 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com