A self-stopping and converging rotary sealing structure

A rotary sealing and anti-rotation technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as increasing manufacturing cost, rotor vibration instability, reducing sealing performance, etc., to increase effective damping and Effective stiffness, reducing the effect of forward swirl and increasing reverse swirl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings and technical principles.

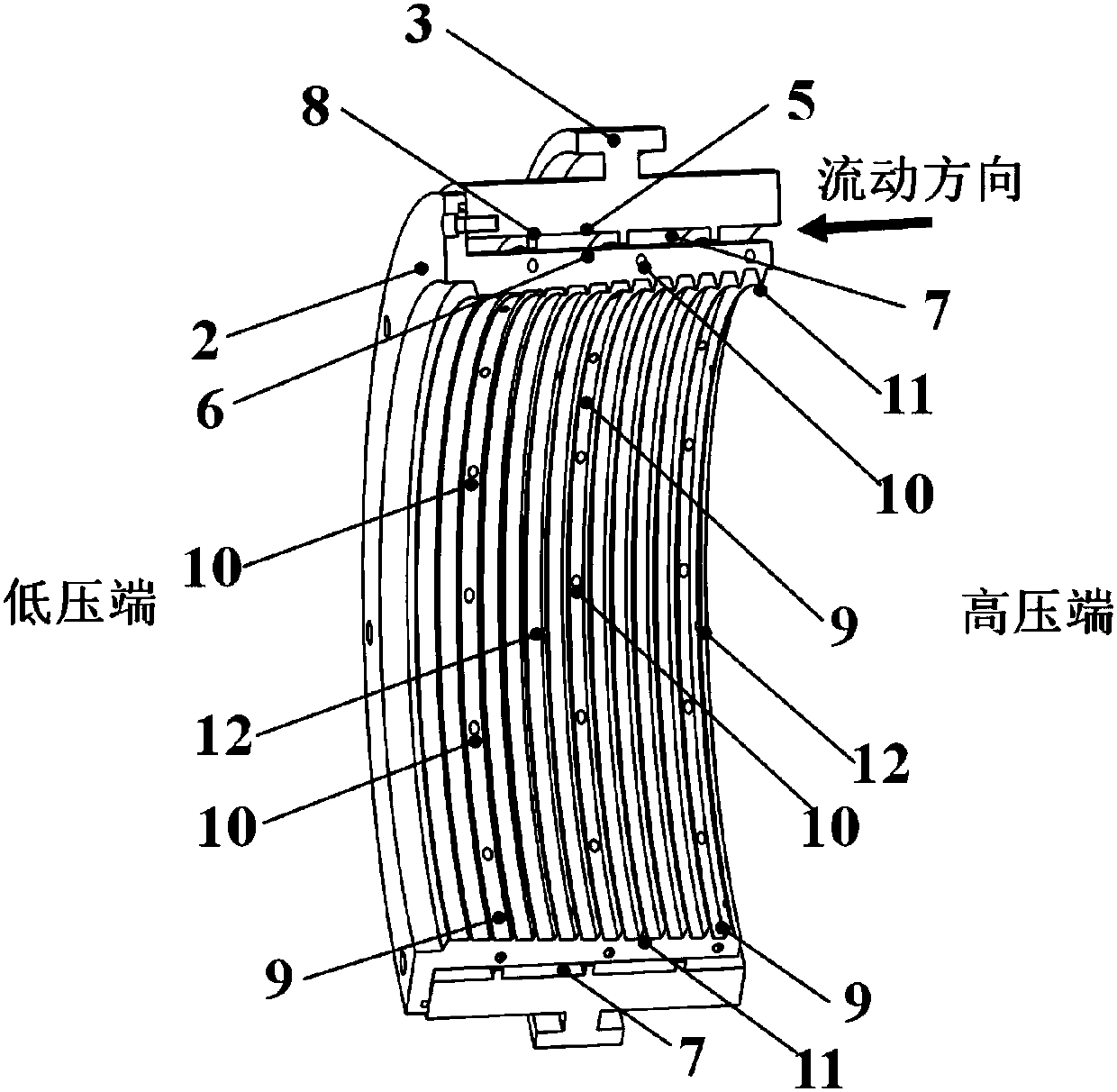

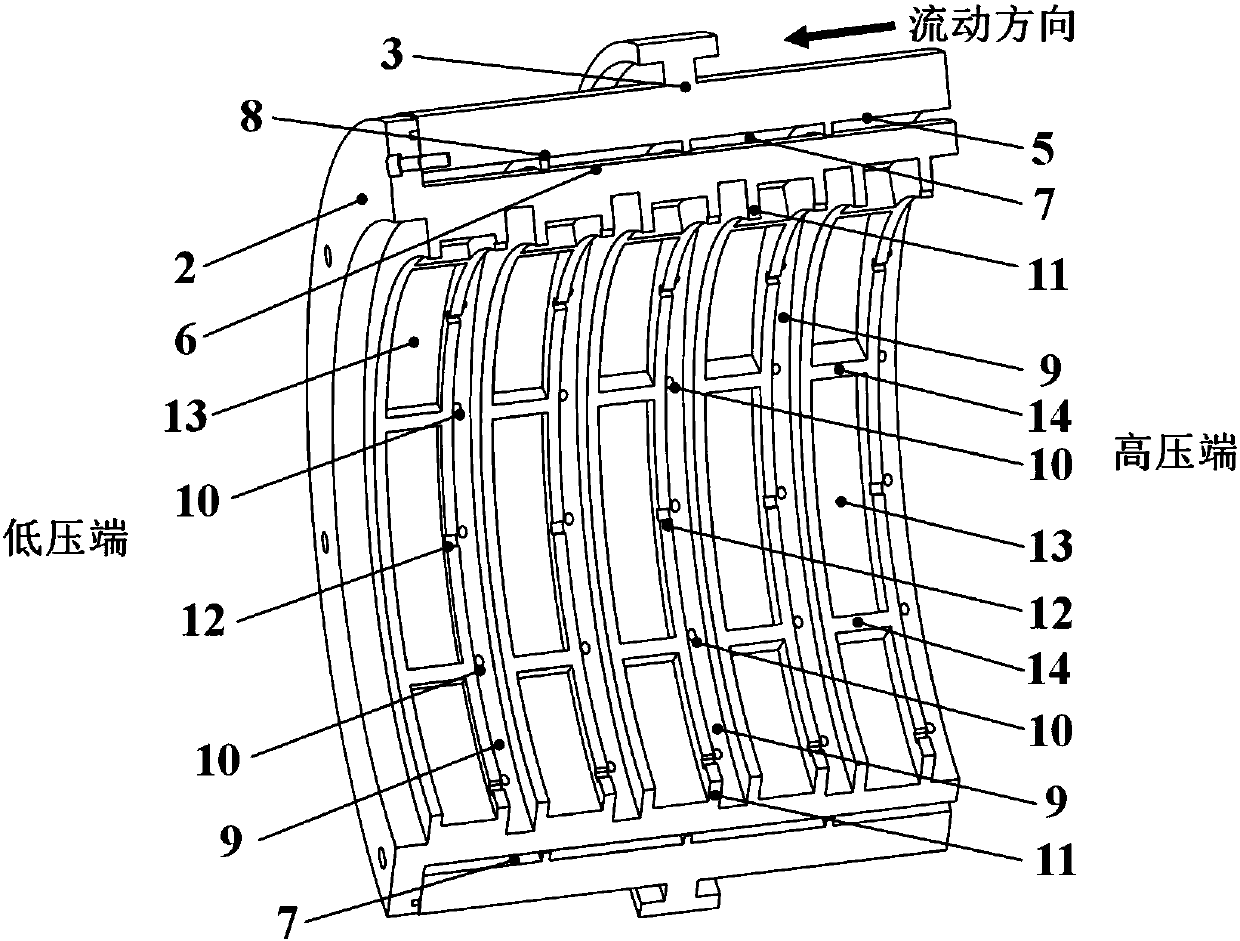

[0056] Concrete structure of the present invention sees appendix figure 1 ~7, the design idea is as follows:

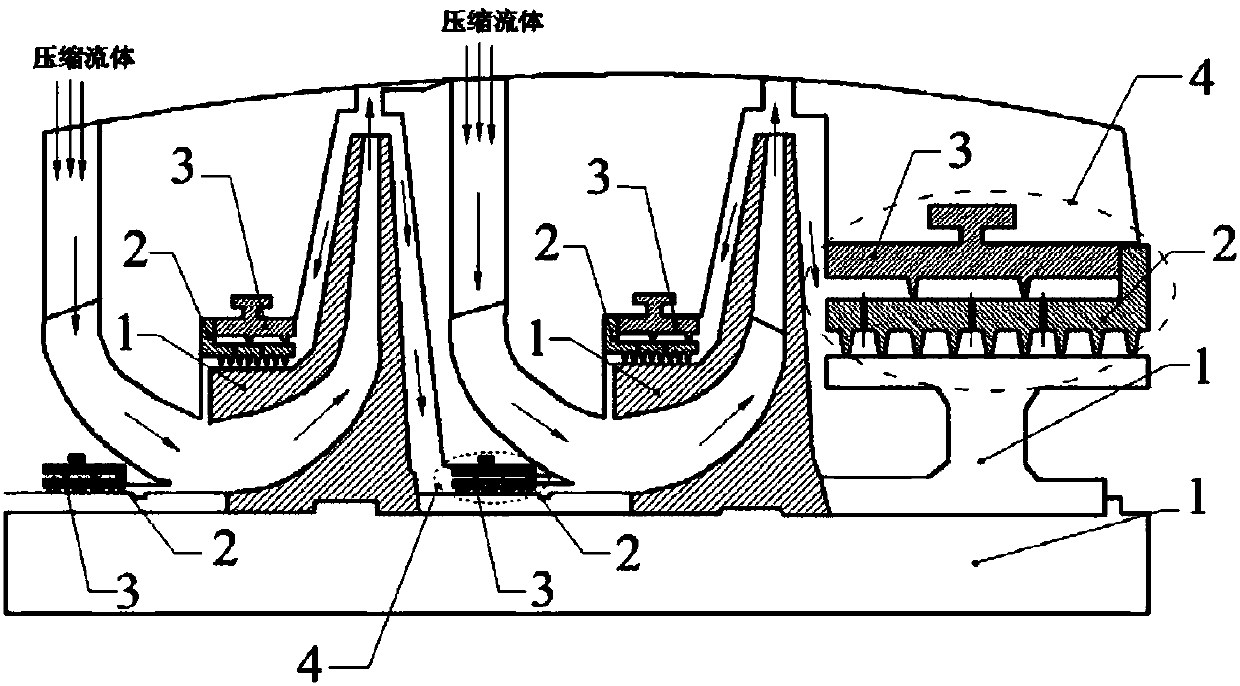

[0057] see figure 1 , the present invention provides a self-rotation-convergent rotary sealing structure, the rotary sealing structure 4 includes a stator outer ring 3 and a stator inner ring 2, the two are coaxially installed. The stator outer ring 3 of the rotary sealing structure 4 of the present invention can replace the traditional sealing structure and be installed at shaft ends, blade tops, partitions and interstages, etc., to enhance the stability of the rotor system. The stator inner ring 2 is installed on the stator outer ring 3 through bolts. The inner ring 2 of the stator and the rotating part 1 form the leakage channel of the working fluid.

[0058] Referring to FIG. 2 , the stator outer ring 3 and the stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com