MEMS (micro-electromechanical system) variable capacitor with linear C-V (capacitance-voltage) characteristic and low-stress double-lever structure

A C-V, low stress technology, applied in the direction of capacitors that change the distance between electrodes, can solve the problems of increasing the complexity of the capacitance control circuit, the limitation of the spacing adjustment range, the influence of precision noise, etc., to increase the capacitance variation range and reduce the control. The effect of high voltage and linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

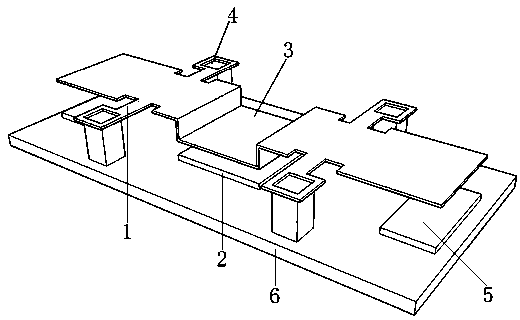

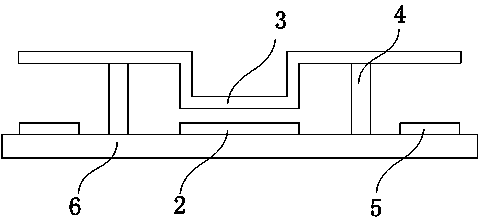

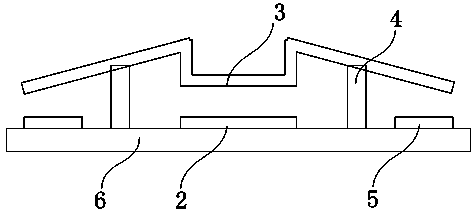

[0019] Such as figure 1 , figure 2 As shown, the low-stress double-lever structure MEMS varactor with linear C-V characteristics includes torsion beam 1, lower plate 2, upper plate 3, anchor point 4, driving electrode 5 and dielectric substrate 6, lower plate 2, The driving electrode 5 and the anchor point 4 are arranged on the dielectric substrate 6, the two ends of the upper pole plate 3 are supported and fixed on the anchor point 4 by the torsion beam 1, the middle part of the upper pole plate 3 is opposite to the lower pole plate 2, and the upper pole plate 3 The end of the electrode plate 3 faces the drive electrode 5 . Such as image 3 As shown, a linearly increasing voltage is applied to the driving electrode 5, and the end of the upper pole plate 3 moves downward, and an electrostatic force is generated between the outer end of the upper pole plate 3 and the driving electrode 5, and the outer end of the upper pole plate is affected by the electrostatic force toward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com