Disassembly-prevention exhaust lock valve

An exhaust valve, anti-disassembly technology, applied in valve details, valve devices, devices to prevent accidental or unauthorized action, etc. problems, to achieve the effect of extending the service life, preventing the loss of hot water, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

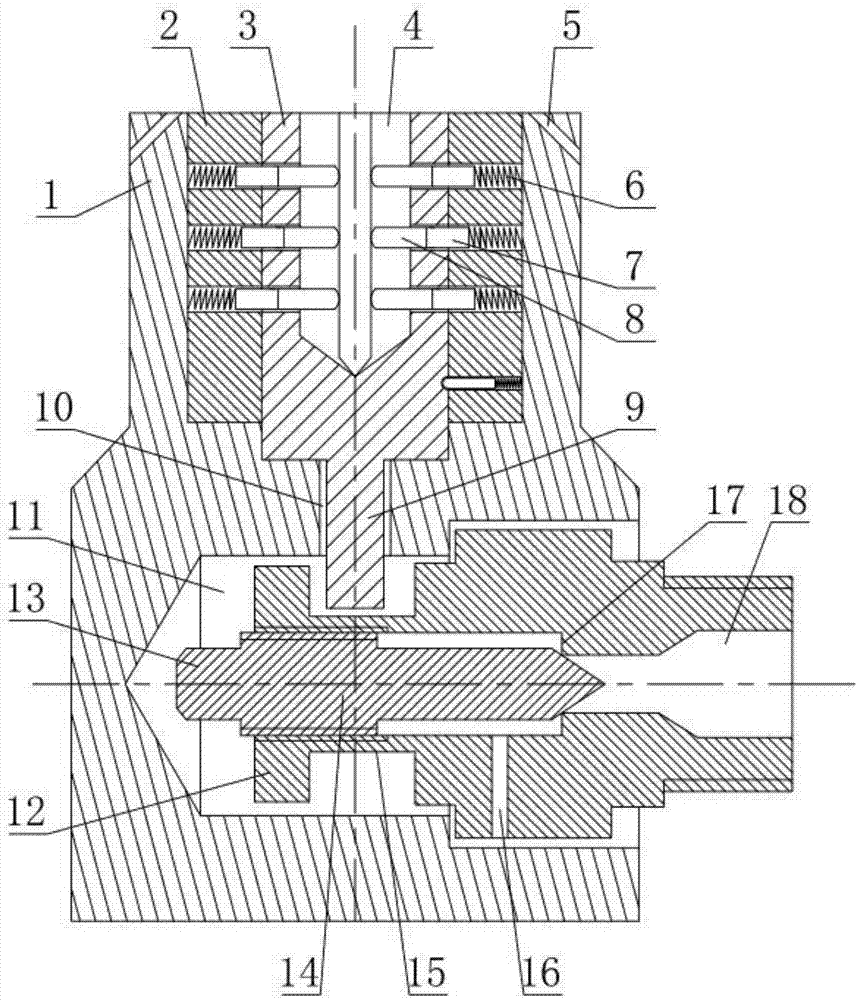

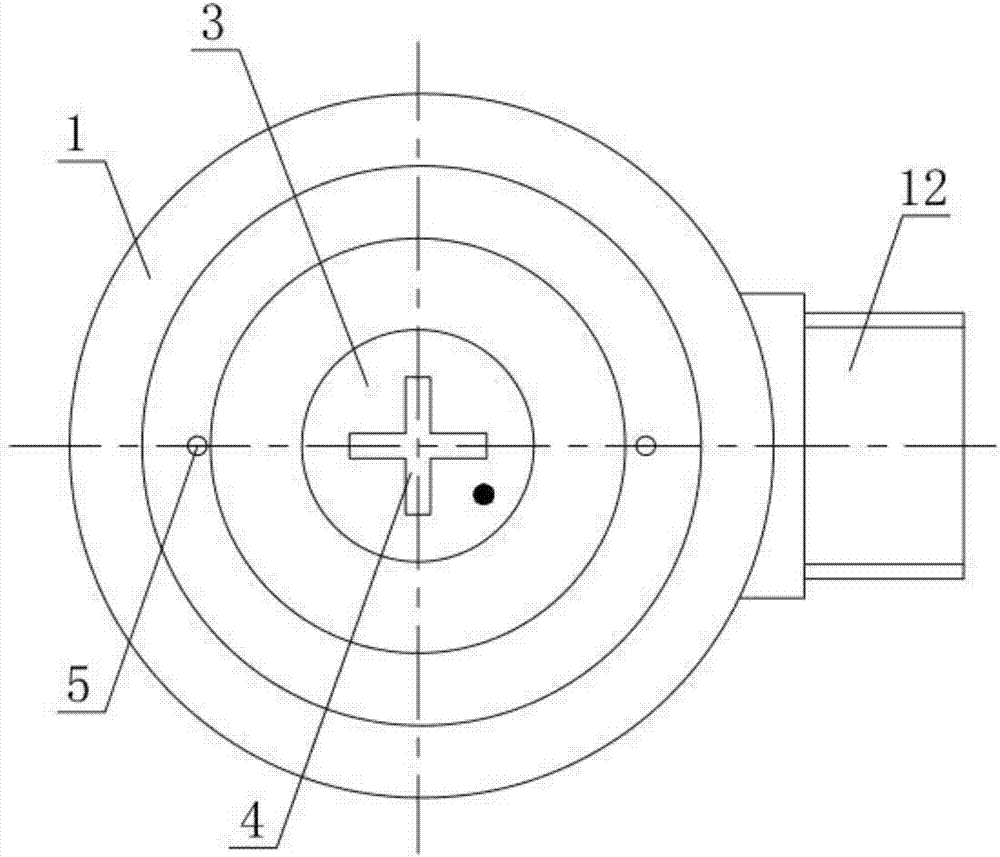

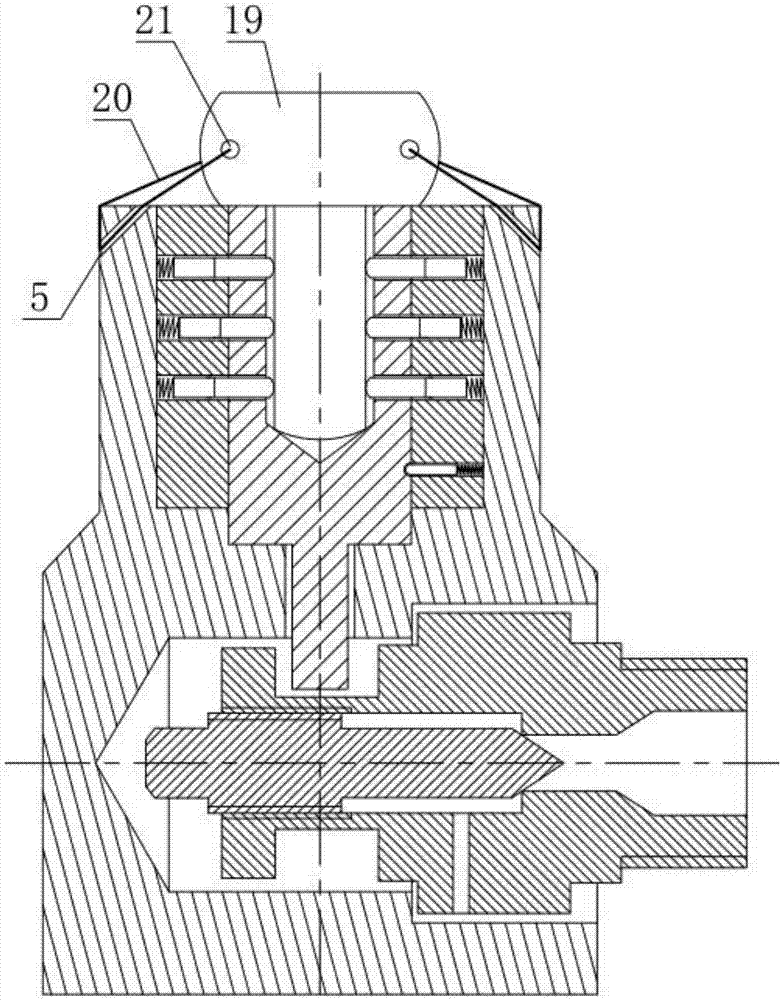

[0021] Such as Figure 1-Figure 6 As shown, the anti-disassembly exhaust lock valve includes a needle exhaust valve and a composite lock. The composite lock is composed of a tamper-proof cover 1, an anti-theft lock built in the upper part of the tamper-proof cover 1, a key (omitted in the figure) and a sealing piece 19 that cooperate with the anti-theft lock. The lateral opening of the exhaust valve is inserted into the cavity 11 horizontally. The top of the laterally inserted cavity 11 is provided with a longitudinal through hole 10 communicating with the upper part of the anti-demolition cover 1. The bottom surface of the lock cylinder 3 of the anti-theft lock is provided with a The lock pin 9 moved by the longitudinal through hole 10, the outer peripheral surface of the lock core 3 is provided with an oblique arc U-shaped groove 22, and the inner peripheral surface of the lock body 2 of the anti-theft lock is provided with an oblique arc U-shaped groove. 22 corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com