Shell and manufacturing method therefor, and terminal equipment

A manufacturing method and housing technology, applied in the electronic field, can solve the problems of unfavorable thin and portable design of mobile terminals, wide mobile terminal machine width, and high cost, so as to save FPC boards and connectors, save installation space, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the various embodiments of the present invention will be described in detail below with reference to the accompanying drawings. However, a person of ordinary skill in the art can understand that, in each embodiment of the present invention, many technical details are proposed for the reader to better understand the present application. However, even without these technical details and various changes and modifications based on the following embodiments, the technical solution claimed in this application can be realized.

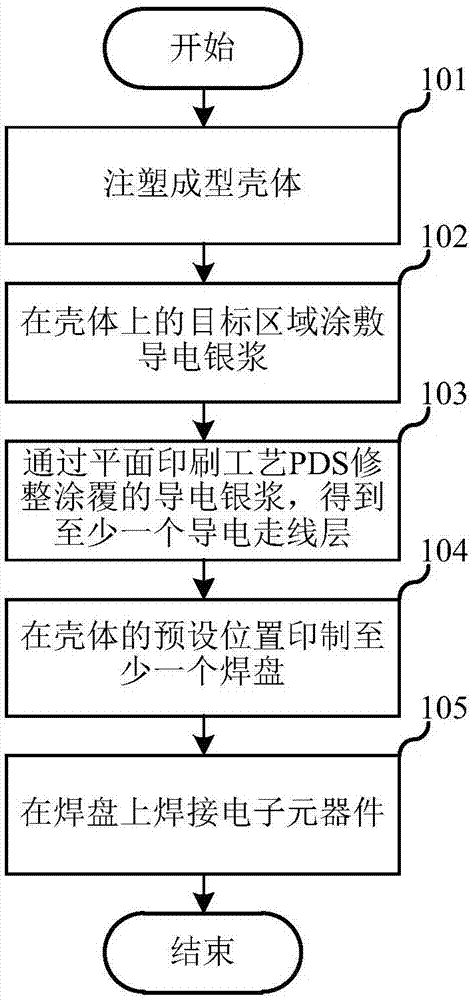

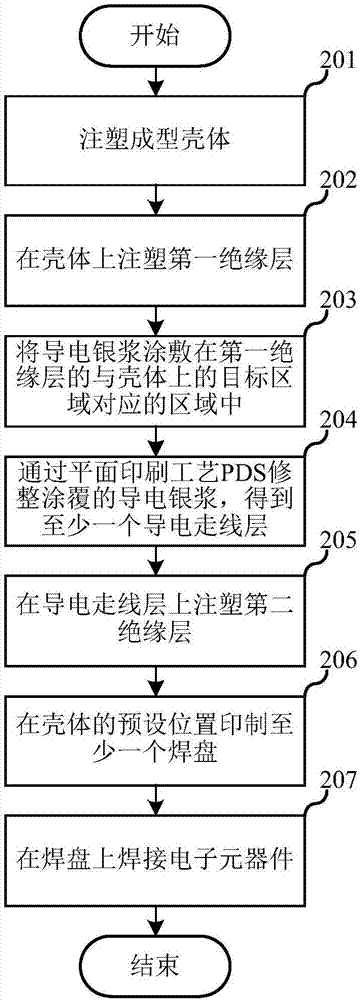

[0021] The first embodiment of the present invention relates to a manufacturing method of a housing, such as figure 1 Shown:

[0022] Step 101: Injection molding the shell.

[0023] Specifically, the use of injection molding technology to inject metal or non-metal materials into the shell according to the shell model is consistent with the prior art and wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com