A kind of functionalized graphene airgel and preparation method thereof

An aerogel and functional technology, applied in the field of composite materials, functionalized graphene aerogels and their preparation, can solve the problems of increasing the difficulty and cost of production, reducing the efficiency of production, and being difficult to meet the requirements of industrialized and efficient production, and the like, Achieve the effect of low cost, simple and efficient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

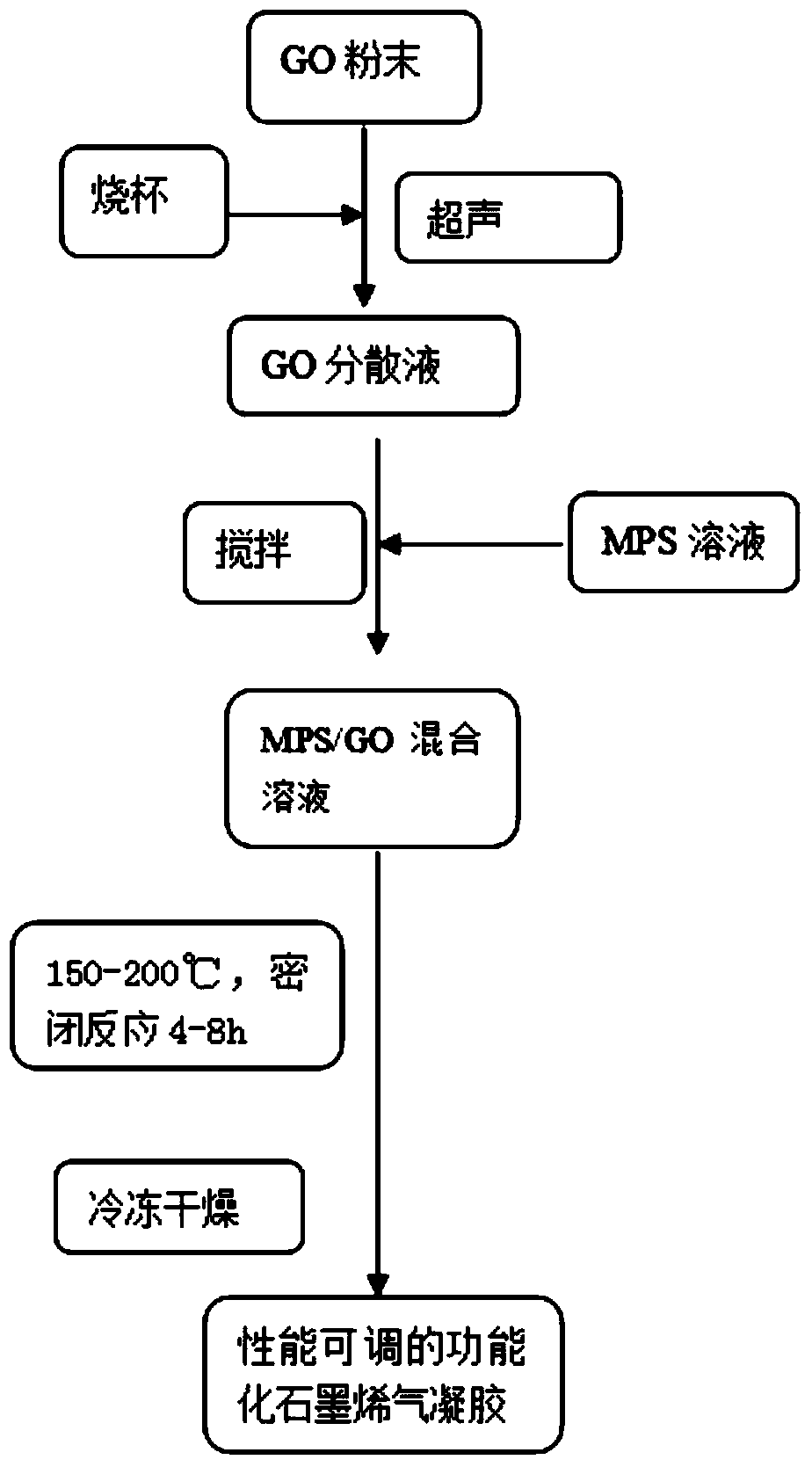

[0020] A functionalized graphene airgel with adjustable properties and a preparation method thereof, the process of which is as follows figure 1 , including the following steps:

[0021] (1) Graphite oxide (GO) was added into deionized water, and a uniform dispersion was obtained by ultrasonication for 30 minutes, and the concentration of graphite oxide in the dispersion was controlled to be 2-4 mg / mL.

[0022] (2) Calculated according to the mass ratio, that is, the mass ratio of MPS:GO is 1:30-20:30, the MPS solution is added to the obtained GO dispersion, and stirred for 10 minutes.

[0023] (3) Move the fully stirred mixed solution into a reaction kettle, seal it, heat at a controlled temperature of 150-200° C. for 4-8 hours, and freeze-dry the product to obtain a functionalized graphene airgel with adjustable properties.

[0024] (4) Perform Raman spectroscopic analysis on the prepared functionalized graphene airgel with adjustable properties.

[0025] (5) Analyze the p...

Embodiment 1

[0029] Functionalized graphene airgel with adjustable performance and preparation method thereof (specific process such as figure 1 shown):

[0030] Add 30mg of graphite oxide (GO) into a beaker with 10mL of deionized water, and ultrasonicate for 30min to obtain a uniform dispersion. Transfer 10 uL of the MPS solution to the beaker containing the GO solution and stir for 10 min. The fully stirred mixed solution was moved to a reaction kettle, sealed, heated at a controlled temperature of 180° C. for 6 hours, and the product was freeze-dried to obtain a functionalized graphene airgel with adjustable properties.

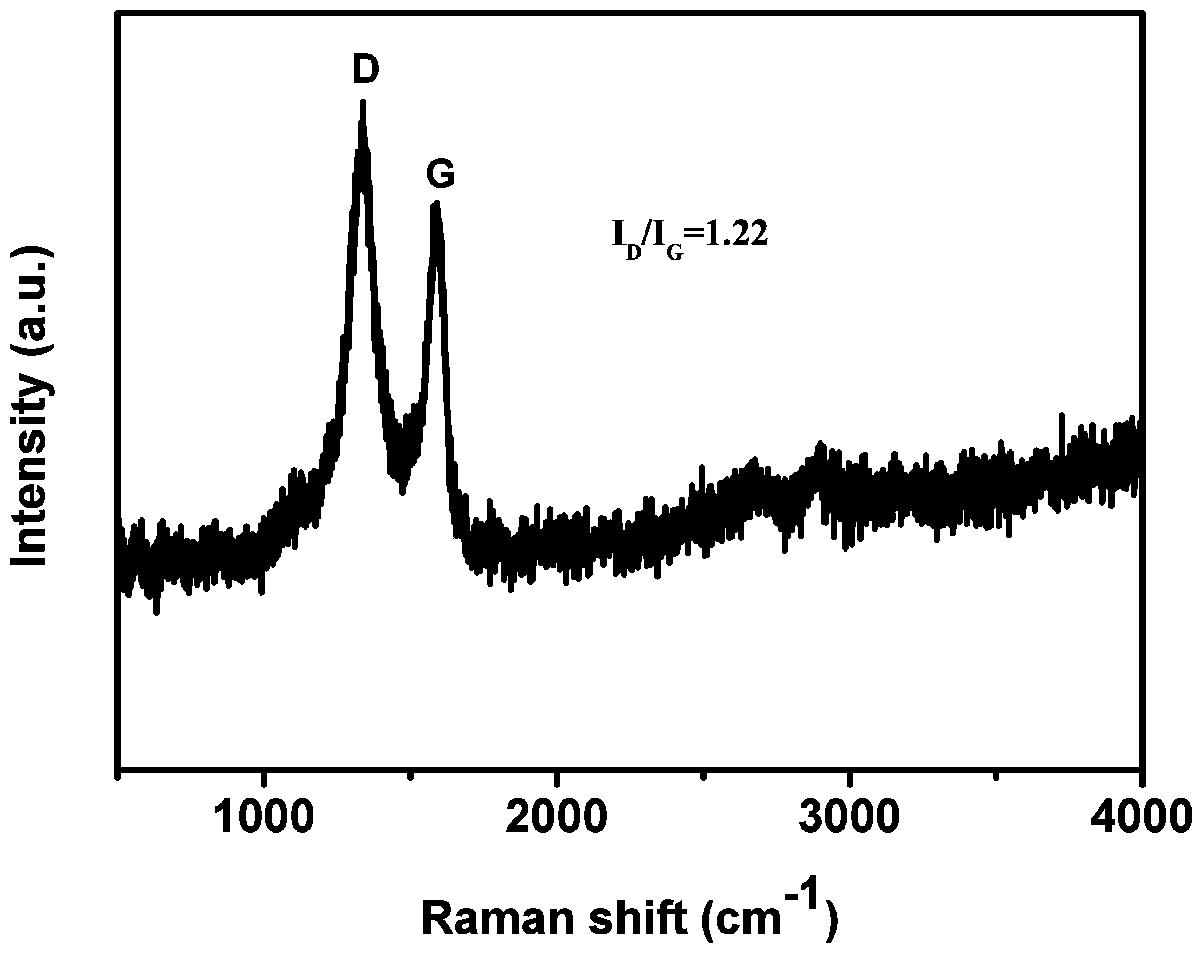

[0031] The Raman spectrogram of the functionalized graphene airgel with adjustable performance prepared in the above-mentioned embodiment 1, as figure 2 As shown, I D / I G =1.15, indicating that graphite oxide was reduced to graphene.

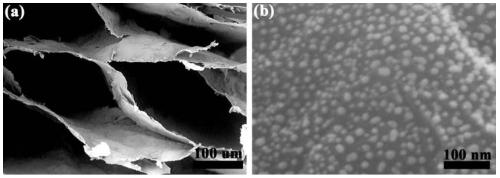

[0032] The scanning electron micrograph of the performance adjustable functionalized graphene airgel prepared in the above-menti...

Embodiment 2

[0036] Add 30mg of graphite oxide (GO) into a beaker with 10mL of deionized water, and ultrasonicate for 30min to obtain a uniform dispersion. Transfer 20 uL of the MPS solution to the beaker containing the GO solution and stir for 10 min. The fully stirred mixed solution was moved to a reaction kettle, sealed, heated at a controlled temperature of 200° C. for 8 hours, and the product was freeze-dried to obtain a functionalized graphene airgel with adjustable properties.

[0037] The Raman spectrogram of the performance-tunable functionalized graphene airgel prepared in above-mentioned embodiment 2, I D / I G =1.22, indicating that graphite oxide is completely reduced to graphene.

[0038] The scanning electron microscope image of the functionalized graphene aerogel with adjustable properties prepared in the above example 2 shows that the graphene aerogel has a macroporous structure exceeding 100 μm, and there is a macroporous structure and a disordered sheet stacking structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com