Automatic draining tank

A drainage box and automatic technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of complex construction, many consumables, and sundries falling into it, so as to reduce construction difficulty and engineering quantity, and ensure safe operation The effect of reliable, wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

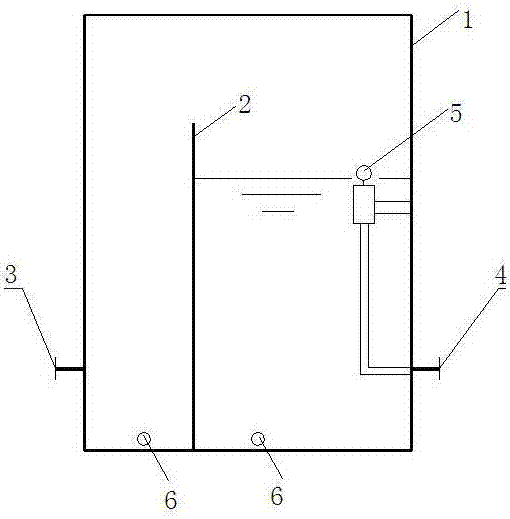

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0021] Taking a 300MW class unit as an example, the automatic drainage box is a rectangular box body 1 with dimensions of 600×600×800mm in length, width and height. The automatic drainage box can be arranged on the ground or at the bottom of the pipe pit. The box body 1 is divided into a water inlet area and a water outlet area by a partition 2. The water level control automatic float 5 valve is installed in the water outlet area to control the sealing of the water outlet 4. The water outlet 4 is connected to the condenser.

[0022] when working,

[0023] The normal working pressure is atmospheric pressure, and when just starting to work, there is no water level in the water inlet area and the water outlet area, and now the float 5 valve in the water outlet area falls, and the cap seals the water outlet 4.

[0024] When the unit is put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com