High-efficient power-grid on-site construction inspection system

A technology of on-site construction and inspection system, applied in the field of inspection, can solve the problems such as failure to achieve the purpose of inspection, limitations, etc., and achieve the effect of improving inspection efficiency and expanding inspection scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described in conjunction with the following examples.

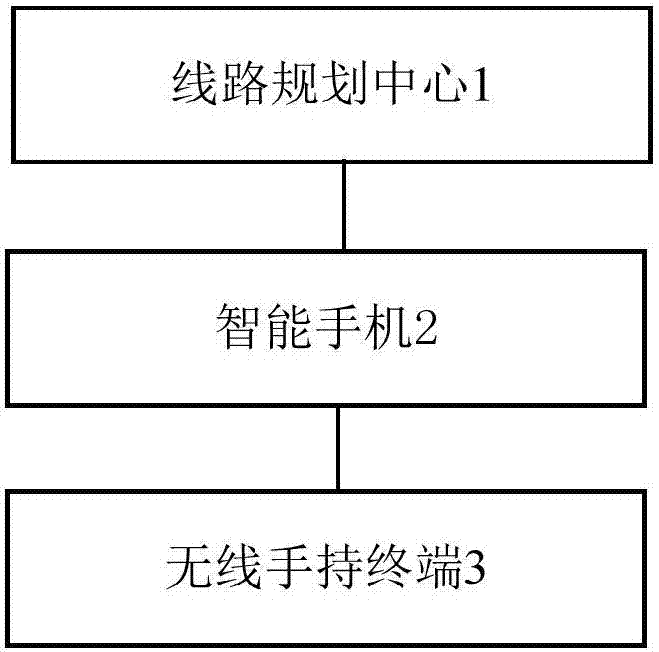

[0013] see figure 1 , an efficient power grid site construction inspection system in this embodiment includes a line planning center 1, a smart phone 2, and a wireless handheld terminal 3. The construction personnel carry the smart phone 1 and receive the power grid construction line issued by the line planning center 3. The inspection personnel use the wireless handheld terminal 3 to communicate with the smart phone 2 carried by the construction personnel to realize on-site inspection; specifically:

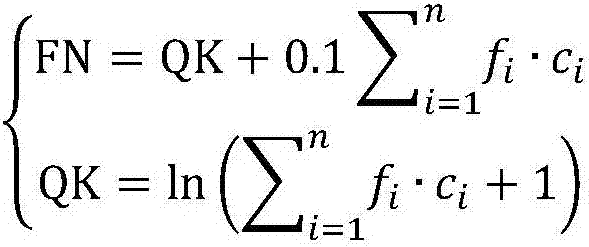

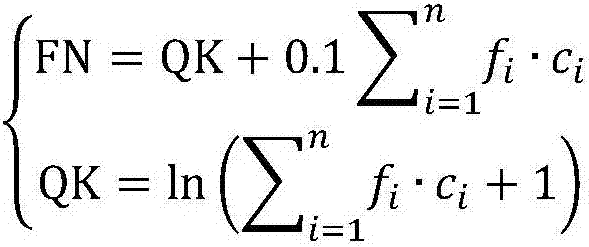

[0014] Step 1: Install a standardized operation system on the smart phone 2 carried by the construction personnel. When the standardized operation system receives the power grid construction line issued by the line planning center 1, it uses the smart phone 2 to collect information on the construction personnel, and sends The collected information is fed back to the line planning cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com