Method for preventing cam kickback of spring operating mechanism and device for realizing the method

A technology of operating mechanism and cam, which is applied to high-voltage/high-current switches, high-voltage air circuit breakers, electrical components, etc., can solve the problems of cam reverse strike, closing buffer bearing breakage, mechanism shell cracking, etc., to prevent The effect of cam kickback, reduction of output power and speed, and increase of damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

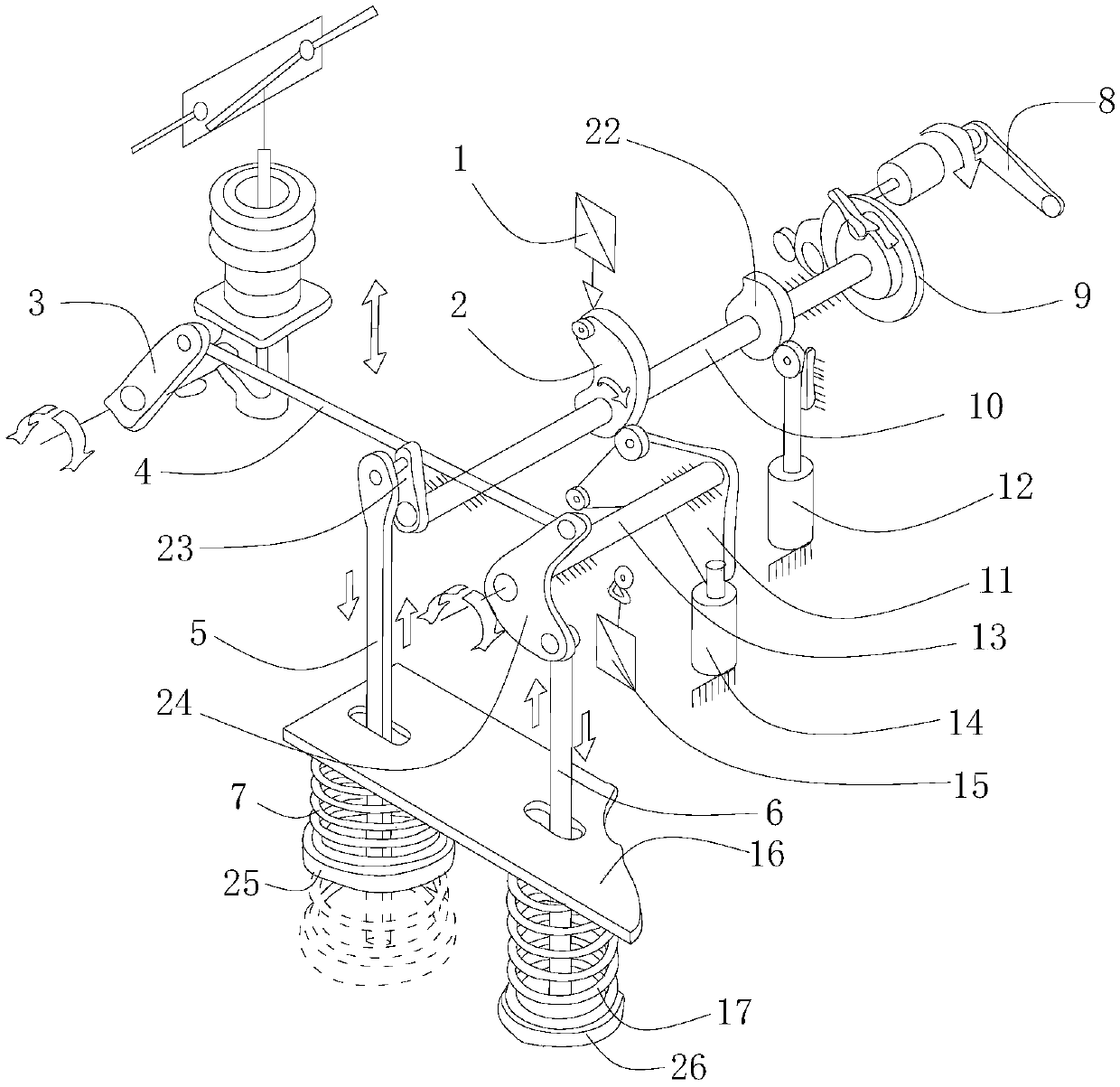

[0028] The method for preventing spring operating mechanism 35 cams from kicking back comprises the steps:

[0029] Step 1. Install a protective cover 30 above the K9 relay 31 of the circuit breaker control box;

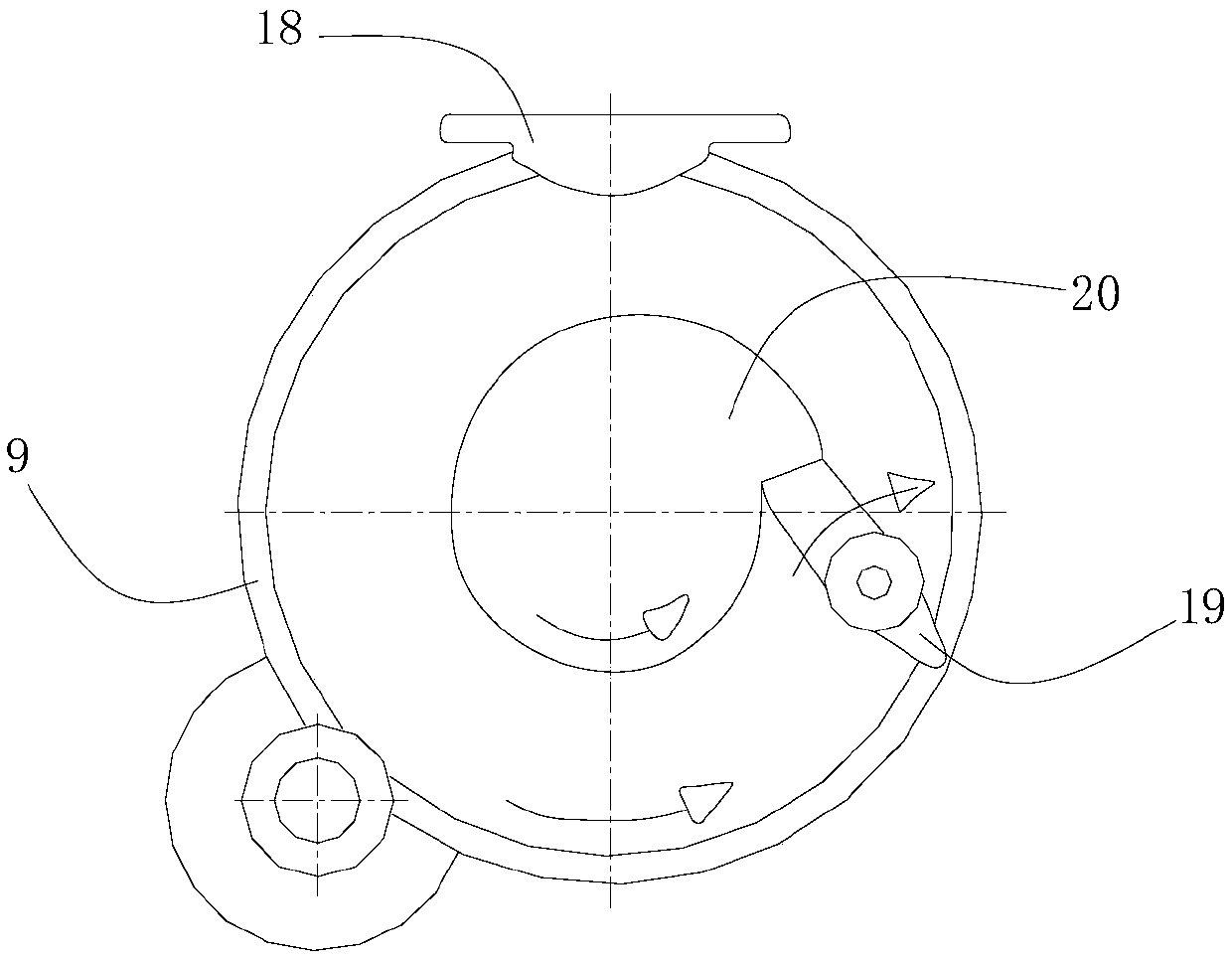

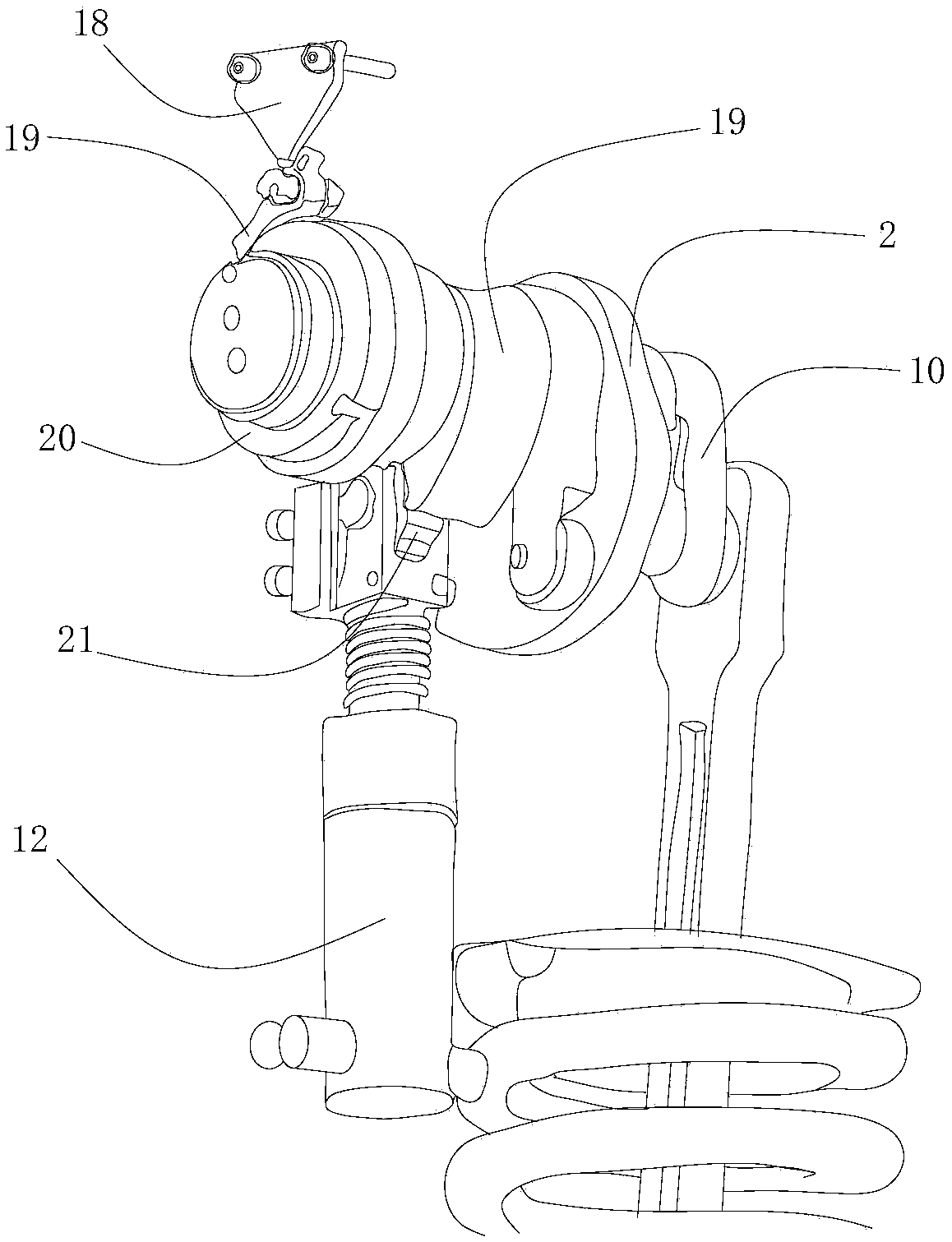

[0030] Step 2. The local / remote closing operation is performed 3 times each, and the energy storage time of the original FA5 type operating mechanism, the number of visible teeth of the energy storage gear 9 and the backlash angle of the energy storage ejector rod 19 are measured for each closing operation; this implementation In the example, the 360° energy storage gear has a total of 85 teeth, of which 6.5 teeth are covered by the triangular plate, so the relationship between the angle of the energy storage gear and the number of teeth is 4.235° / tooth. Operating experience shows that the stop position of the energy storage ejector pin must be within 90° , that is, the stop position of the energy storage ejector pin is required to be within 18 visible teeth.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com