Material crushing and grinding device with improved material crushing cutters and improved discharge port

A grinding device and discharge port technology, which is applied in the field of crushing device, can solve the problems of safety accidents, repeated crushing, poor crushing effect, etc., and achieve the effect of avoiding safety accidents and complete crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

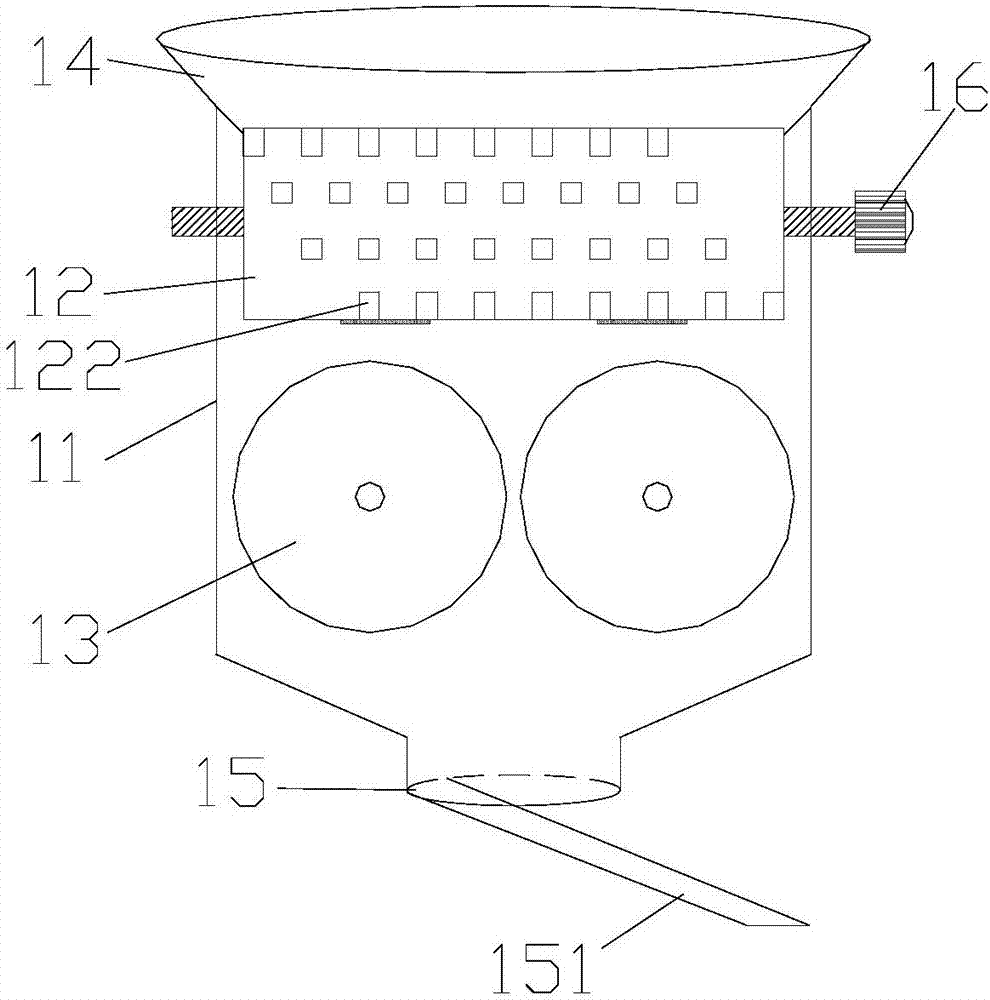

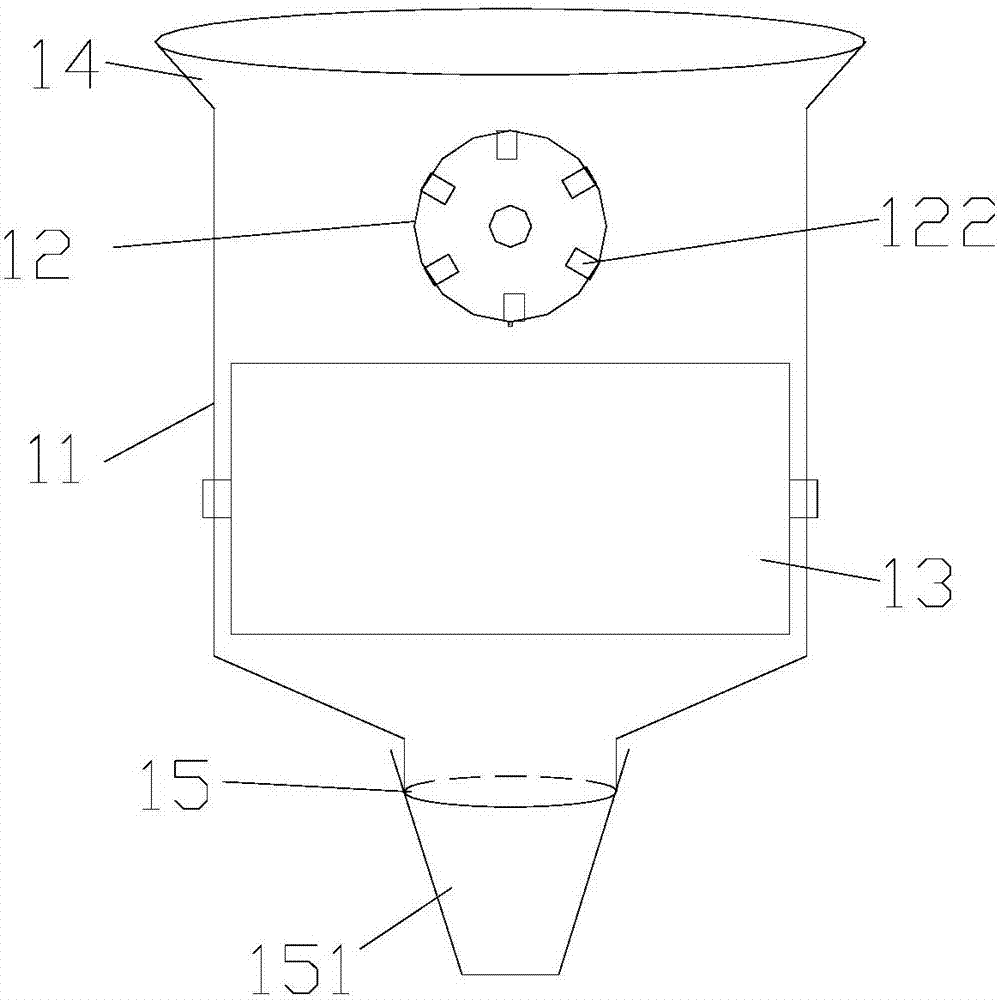

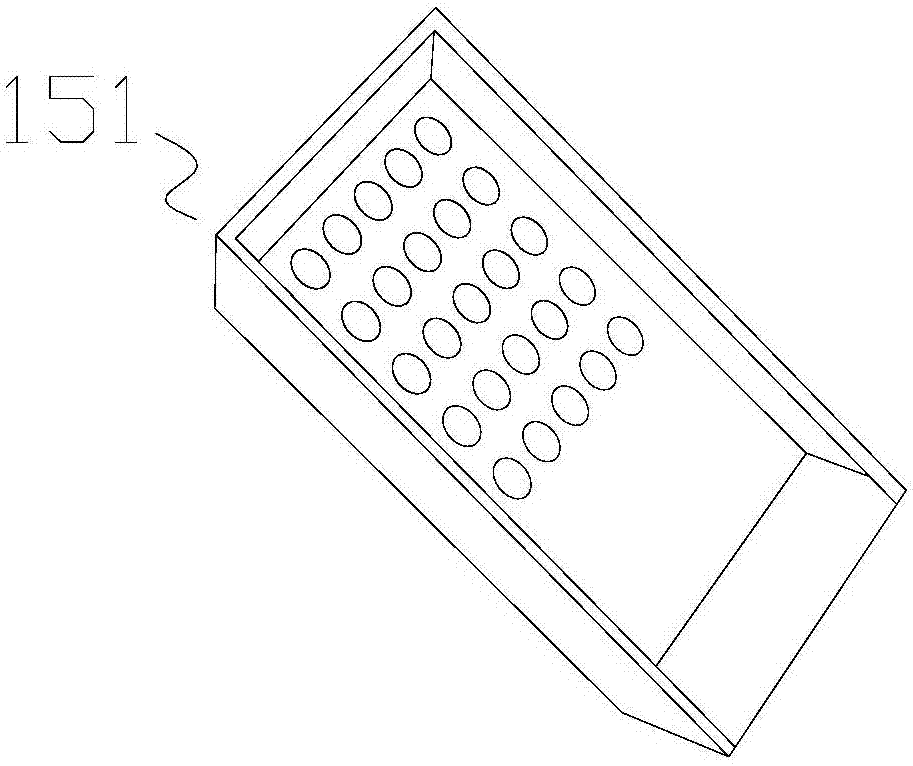

[0016] Please also see Figure 1 to Figure 3 , figure 1 It is a schematic diagram of the main view structure created for the present invention, figure 2 Schematic diagram of the side view structure created for the present invention. image 3 It is a structural schematic diagram of the debris screening tank in the present invention.

[0017] A crushing device for improving the crushing knife and the discharge port, including a casing 11, a crushing drum 12 and a grinding roller 13, the crushing drum 12 is arranged at the upper end of the casing 11, and the grinding roller 13 is arranged at the casing 11 The inner lower end, and the axial direction of the scrap drum 12 is perpendicular to the axial direction of the grinding roller 13 .

[0018] The casing 11 is cylindrical, with a feed opening 14 at its upper end and a discharge opening 15 at its lower end.

[0019] The crushing drum 12 is horizontally mounted on the upper part of the casing 11 and is located directly below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com