Flat filament rim charge recycling device

A technology of scrap recycling and flat yarn, which is applied in the field of plastic flat yarn production, can solve the problems of time-consuming and labor-intensive, high labor intensity, cumbersome collection process of flat yarn scrap, etc., so as to improve production efficiency, save production energy consumption, and achieve crushing effect thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

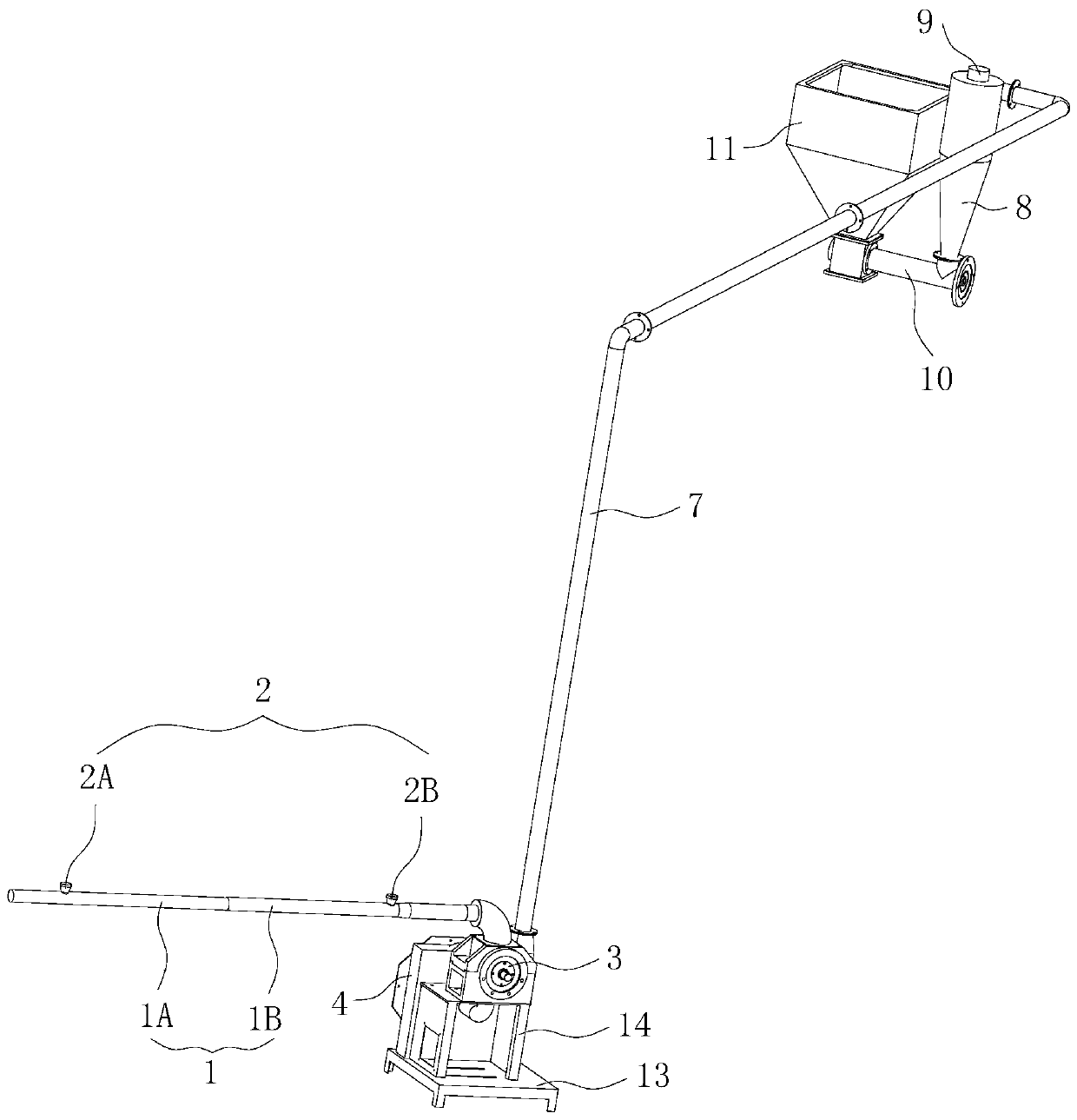

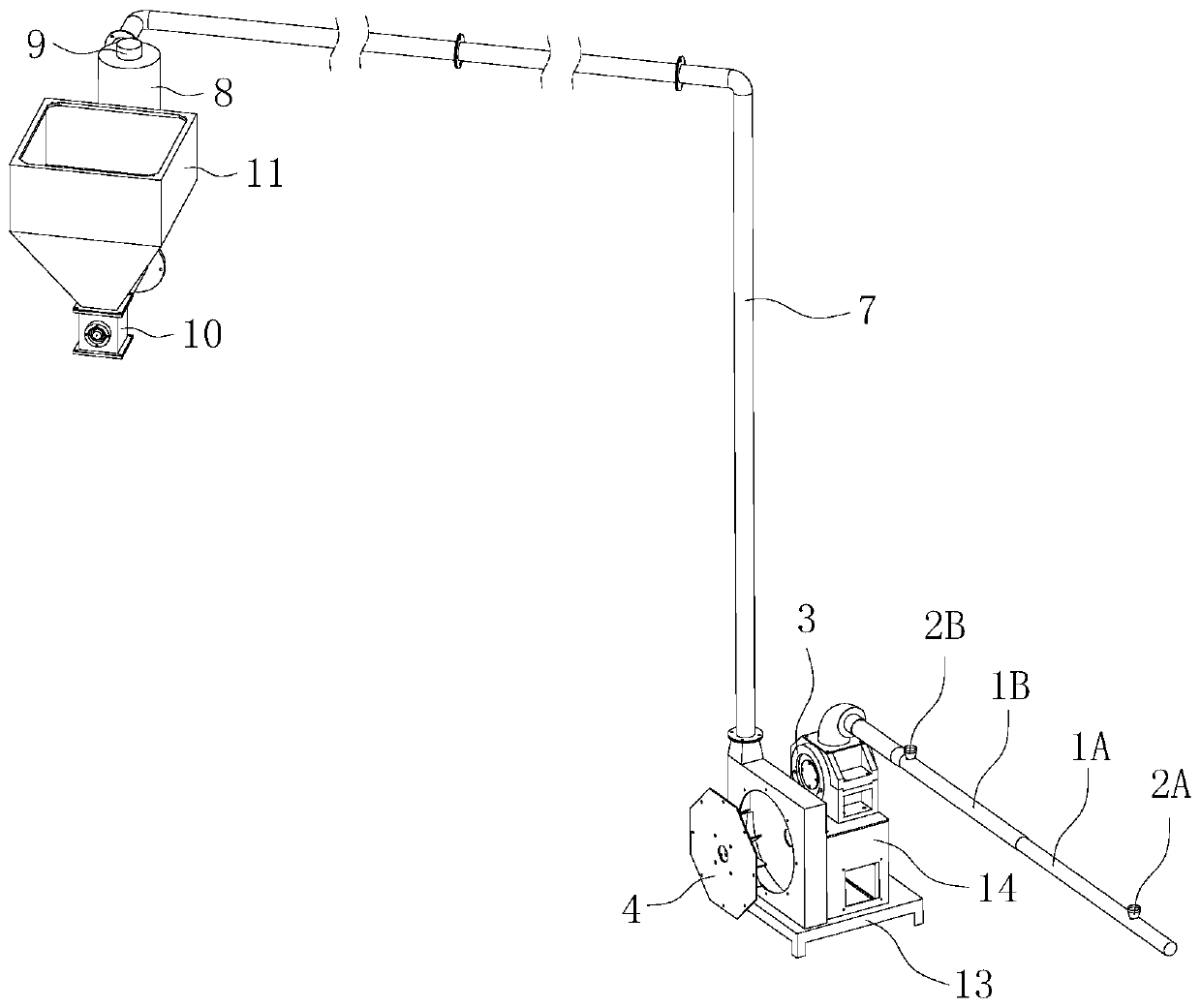

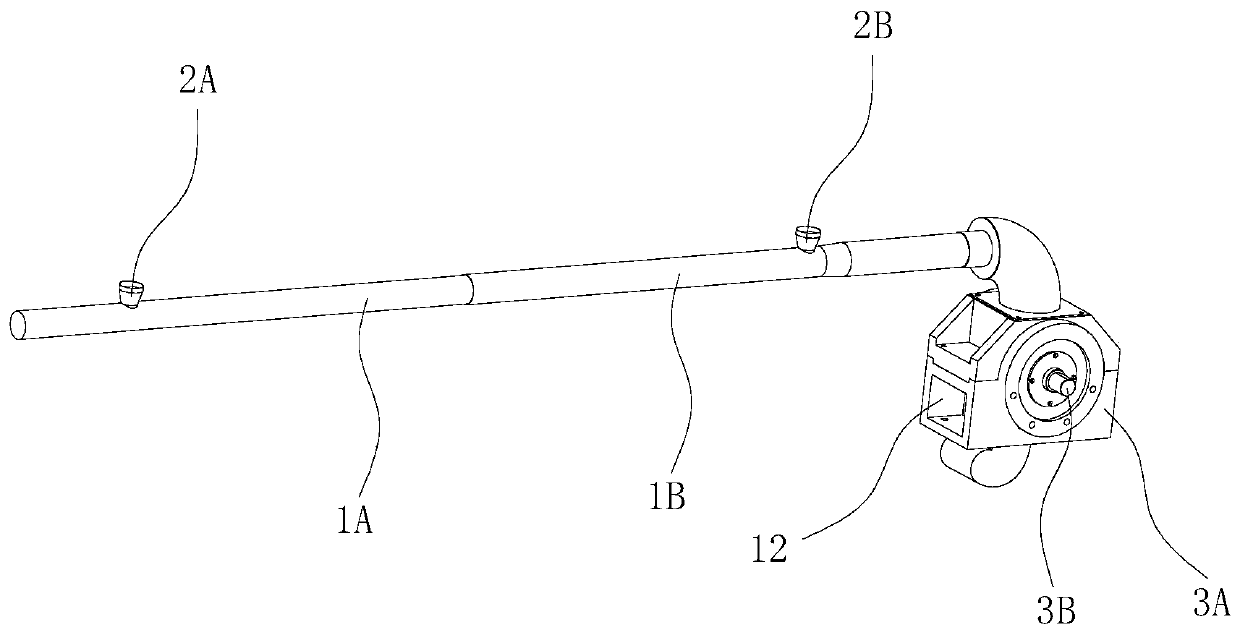

[0034] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0035] In this example, if figure 1 and figure 2 Shown, a kind of flat yarn scrap recovery device, comprises the guide wire pipe 1 that is arranged on the production line below, vermicelli mechanism 3 and suction blower fan 4. The bottom of the guide wire pipe 1 is provided with a base 13, the suction fan 4 is fixedly arranged on the base 13, the base 13 is provided with a support 14, and the fan mechanism 3 is installed on the support 14. Offer at least one import port 2 suitable for sucking waste silk on the wire guide tube 1, the outlet of the wire guide tube 1 communicates with the entrance of the fan mechanism 3, the outlet of the fan mechanism 3 communicates with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com