One-bath dyeing process of brocade-covered cotton Roman cloth

A nylon-coated cotton and process technology, which is applied in the field of one-bath dyeing process of nylon-coated cotton Roman cloth, can solve the problems of producing a large amount of printing and dyeing wastewater, consuming large amounts of water and dyes, and poor dyeing effect, and achieving improved color fastness and dyeing Improvement of performance and shortening of process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The impact of pre-setting process on Roman cloth feel

[0025] The one-bath dyeing process of brocade-coated cotton roman cloth in this embodiment is as follows: cloth turning → steaming → presetting → dyeing → color matching → washing → soaping → drying → finished product. in:

[0026] (1) In the pre-setting process:

[0027] ①The setting method adopts steam setting and natural gas open fire heat setting respectively. The temperature is 190°C, the fabric running speed is 55 yards / min, and the air volume is 100r / min. Among them, steam setting is used as comparative test 1, and natural gas open fire heat setting is used as experiment 1.

[0028]② The setting adopts natural gas open flame heat setting, the fabric running speed is 55 yards / min, the air volume is 100r / min, and the setting temperature is lower than 185°C (select 170°C, 180°C and 183°C as representatives), 185-195°C (Choose 185°C, 187°C, 189°C, 191°C, 193°C, 195°C as representatives), higher t...

Embodiment 2

[0037] Embodiment 2: the influence of dyeing process and soaping process on treatment effect

[0038] The one-bath dyeing process of brocade-coated cotton roman cloth in this embodiment is as follows: cloth turning → steaming → presetting → dyeing → color matching → washing → soaping → drying → finished product. in:

[0039] (1) Pre-setting process, the setting method adopts natural gas open flame heat setting, the temperature is 190 ° C, the fabric running speed is 55 yards / min, and the air volume is 100 r / min.

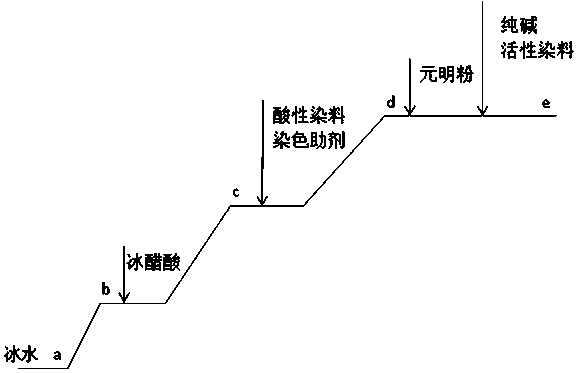

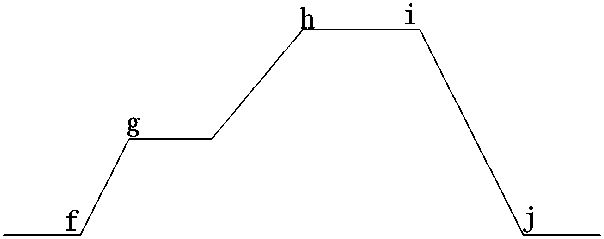

[0040] (2) In the dyeing process, combining figure 1 , the dyeing adopts one-bath dyeing, the dyeing bath ratio is 1:3, the heating rate of stage a→b is 4°C / min, the bath temperature rises to 40°C, and glacial acetic acid is added; the heating rate of stage b→c is 2°C / min, Raise the temperature to 70°C, add 0.5% of acid dye and 1% of rare earth chloride additives, and keep it warm for 10 minutes; the heating rate in the c→d stage is 1.3°C / min, after raising the tem...

Embodiment 3

[0051] Embodiment 3: Utilization of Dyeing Water and Soaping Water

[0052] The one-bath dyeing process of brocade-coated cotton roman cloth in this embodiment is as follows: cloth turning → steaming → presetting → dyeing → color matching → washing → soaping → drying → finished product. in:

[0053] (1) In the presetting process: natural gas open fire is used for heat setting, the temperature is 190°C, the fabric running speed is 55 yards / min, and the air volume is 100r / min.

[0054] (2) In the dyeing process, combining figure 1 , the dyeing adopts one-bath dyeing, the dyeing bath ratio is 1:3, the heating rate of stage a→b is 4°C / min, the bath temperature rises to 40°C, and glacial acetic acid is added; the heating rate of stage b→c is 2°C / min, Raise the temperature to 70°C, add 1.2% of acid dye and 0.1% of rare earth chloride additives, and keep warm for 20 minutes; the heating rate in the c→d stage is 1.3°C / min, after raising the temperature to 98°C, keep warm for 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com