Dyeing Process of Nylon and Cotton Blended Fabric

A technology of blended fabrics and nylon cotton, applied in the field of textile dyeing, can solve the problems of long dyeing process, achieve the effects of shortening the process, excellent fastness performance, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

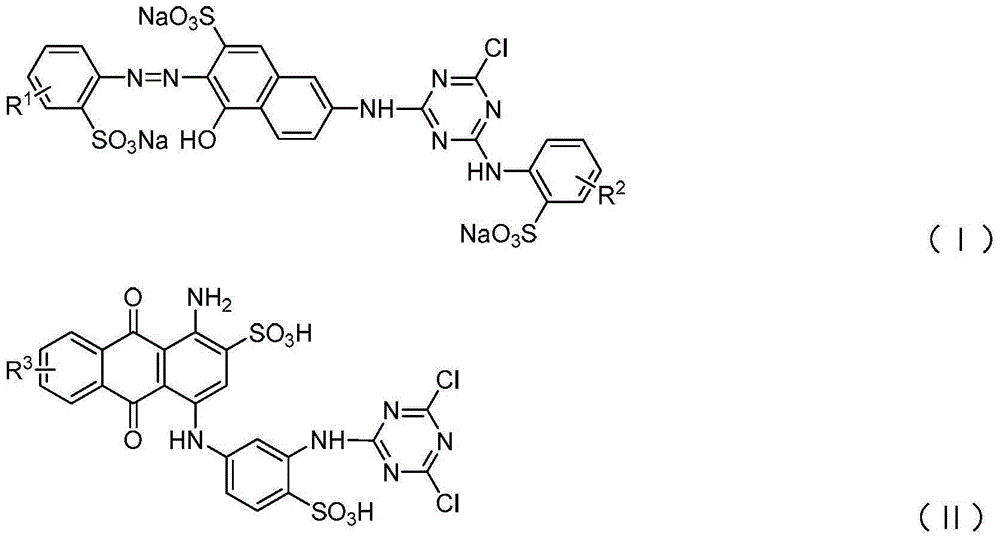

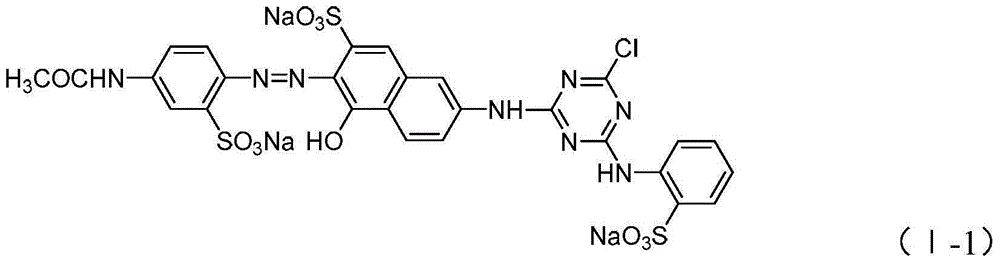

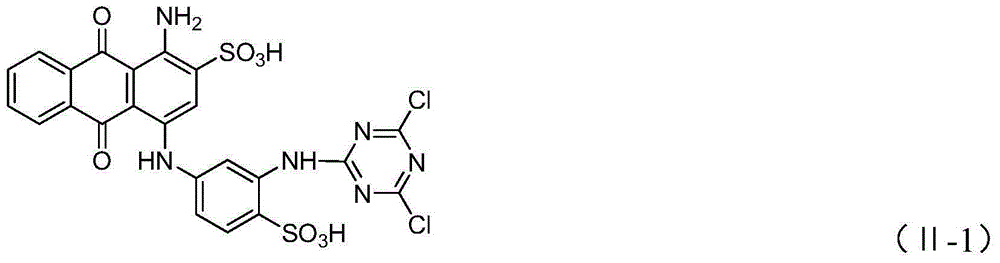

Image

Examples

Embodiment 1

[0033] (1) At room temperature, add 3g of reactive red 9#, 8211g of leveling agent, 1g of sodium bicarbonate and 100g of nylon-cotton blended fabric to 1000ml of water in sequence, raise the temperature to 60°C at a rate of 1°C / min, and then keep warm 30 minutes, add alkali and then keep warm for 30 minutes to complete the dyeing of cotton and obtain dyed semi-finished products;

[0034] (2) Add glacial acetic acid to the dyed semi-finished product obtained in step (1) to adjust the pH to 4.5, then raise the temperature to 80°C at a rate of 1°C / min, keep it warm for 30 minutes, cool down to room temperature, drain, wash with water, and then Raise the temperature to 98°C for soaping, then cool down to room temperature, wash with water, and dry to obtain the finished dyed product. The performance data of the dyed finished product obtained are shown in Table 1.

Embodiment 2

[0036] (1) At room temperature, add 3g of reactive blue 4#, leveling agent OP1g, 1g of sodium bicarbonate and 100g of nylon-cotton blended fabric to 1000ml of water in sequence, raise the temperature to 60°C at a rate of 1°C / min, and then keep warm 30 minutes, add alkali and then keep warm for 30 minutes to complete the dyeing of cotton and obtain dyed semi-finished products;

[0037] (2) Add glacial acetic acid to the dyed semi-finished product obtained in step (1) to adjust the pH to 4.5, then raise the temperature to 80°C at a rate of 1°C / min, keep it warm for 30 minutes, cool down to room temperature, drain, wash with water, and then Raise the temperature to 98°C for soaping, then cool down to room temperature, wash with water, and dry to obtain the finished dyed product. The performance data of the dyed finished product obtained are shown in Table 1.

Embodiment 3

[0039] (1) At room temperature, add dye reactive red 9#3g, leveling agent AN1g, sodium bicarbonate 1g and nylon-cotton blended fabric 100g to 1000ml of water in turn, heat up to 60°C at a rate of 1°C / min, and then keep warm 30 minutes, add alkali and then keep warm for 30 minutes to complete the dyeing of cotton and obtain dyed semi-finished products;

[0040] (2) Add glacial acetic acid to the dyed semi-finished product obtained in step (1) to adjust the pH to 4.5, then raise the temperature to 80°C at a rate of 1°C / min, keep it warm for 30 minutes, cool down to room temperature, drain, wash with water, and then Raise the temperature to 98°C for soaping, then cool down to room temperature, wash with water, and dry to obtain the finished dyed product. The performance data of the dyed finished product obtained are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com