A method for testing the smoke insulation performance of exhaust duct

A detection method and exhaust duct technology, applied in vertical pipes, buildings, building components, etc., can solve the problems of smoke color and short smoke time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

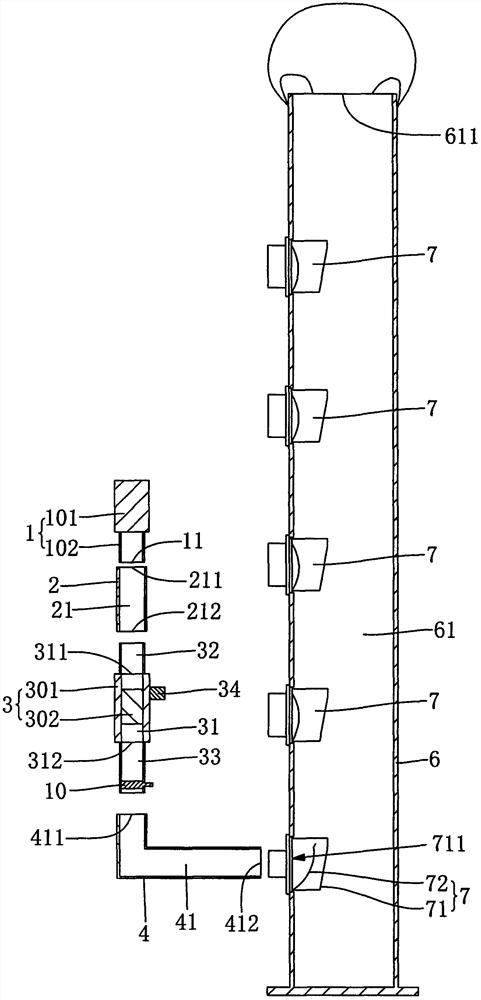

[0028] refer to figure 1 , a method for detecting smoke insulation performance of an exhaust duct, comprising the steps of:

[0029] S01) connecting the smoke generator 1, the first smoke exhaust pipe 2, the fan 3, the second smoke exhaust pipe 4 and the building exhaust duct in sequence;

[0030] S02) Start the smoke generator 1 and the fan 3, the fan 3 sucks the smoke generated by the smoke generator 1 through the first smoke exhaust pipe 2, and blows the smoke into the building exhaust duct through the second smoke exhaust pipe 4.

[0031] It should be noted that: when the smoke generator 1, the first smoke exhaust pipe 2, the fan 3 and the second smoke exhaust pipe 4 are connected in sequence, the four are assembled into a movable detection device to realize the detection of the exhaust duct of the building. Smoke performance.

[0032] refer to figure 1 , the building exhaust duct in this embodiment has a smoke flow channel 61 and an exhaust port 611 communicating with ...

Embodiment 2

[0054] A method for detecting smoke insulation performance of an exhaust duct, comprising the steps of:

[0055] S01) connecting the smoke generator, the first smoke exhaust pipe, the fan, the second smoke exhaust pipe and the building exhaust duct in sequence;

[0056] S02) Start the smoke generator and the fan, the fan sucks the smoke generated by the smoke generator through the first smoke exhaust pipe, and blows the smoke into the building exhaust duct through the second smoke exhaust pipe.

[0057] In this embodiment, the smoke generator includes a smoke generator body, which is provided with a smoke outlet for discharging smoke; the first smoke exhaust pipe is provided with a first smoke exhaust channel, and the first smoke exhaust channel is There is a first smoke inlet and a first smoke exhaust port; a smoking channel is provided on the fan, and a third smoke inlet and a third smoke exhaust port are provided on the smoking channel; a second smoke exhaust port is provid...

Embodiment 3

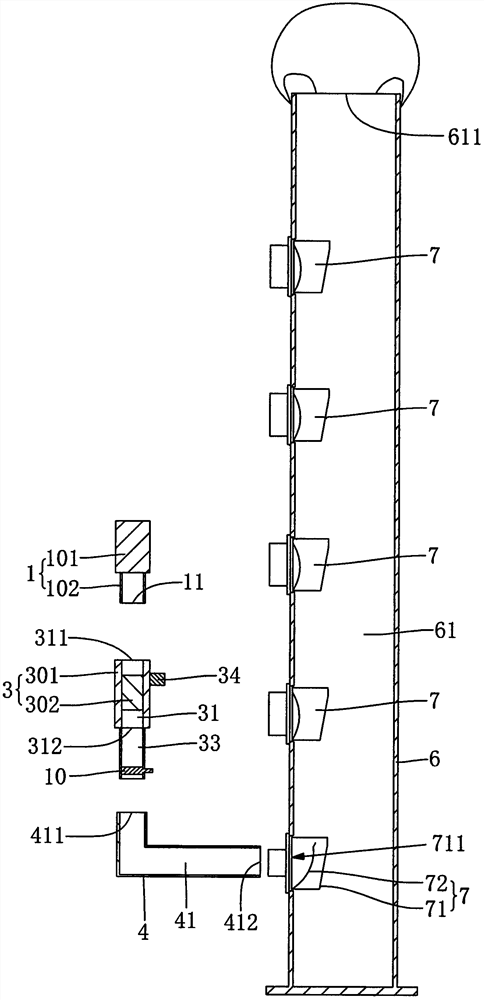

[0061] refer to figure 2 , a method for detecting smoke insulation performance of an exhaust duct, comprising the steps of:

[0062] S01) connecting the smoke generator 1, the blower fan 3, the smoke exhaust pipe 4 and the building exhaust duct sequentially;

[0063] S02) Start the smoke generator 1 and the fan 3, the fan 3 sucks the smoke generated by the smoke generator 1, and blows the smoke into the exhaust duct of the building through the smoke exhaust pipe 4.

[0064] It should be noted that when the smoke generator 1, fan 3 and smoke exhaust pipe 4 are connected in sequence, the three are assembled into a movable detection device to realize the detection of the smoke insulation performance of the building exhaust duct.

[0065] refer to figure 2 , the building exhaust duct in this embodiment has a smoke flow channel 61 and an exhaust port 611 communicating with the smoke flow channel 61. Since the exhaust duct is installed on the building, when the smoke in the buil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com