Anti-drop mechanism

A technology of anti-drop part and lifting lug, which is applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of poor working stability, abnormal opening of stopper, failure of anti-dropping device, etc., to reduce the risk of accidental contact. probability, improve safety and reliability, and enhance the effect of locking reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

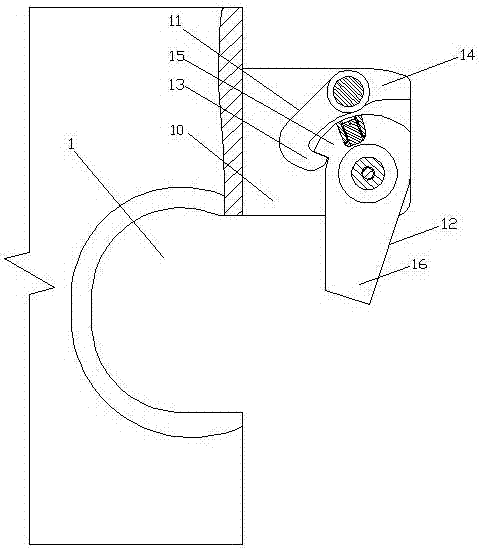

Embodiment 1

[0036] An anti-off mechanism, including a block 12 that is rotatably connected to the notch 10 on the lifting lug, and also includes a locking block 11 that is rotatably connected to the notch 10 on the lifting lug, and the locking block 11 and the block 12 Locking connection, the locking block 11 includes a hook portion 13 and a force receiving portion 14, the block 12 includes a locking portion 15 and an anti-off portion 16, and the locking portion 15 is located in the notch 10 on the lifting lug Inside, the anti-off part 16 is located in the ear hole 1 of the lifting ear; the stopper 12 performs a pendulum movement, the stopper 12 swings clockwise and locks with the lock hook part 13 of the locking block 11, and the lock hook part 13 is in the lower position. In the pressed state, the block 12 swings counterclockwise to unlock the locking block 11, and the locking hook portion 13 is in a lifted state.

[0037] This embodiment is the most basic implementation, and also inclu...

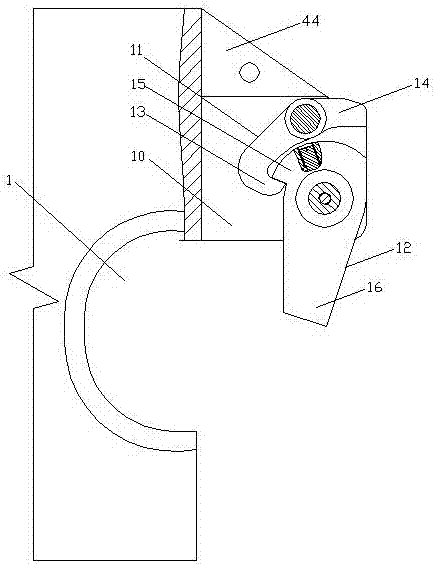

Embodiment 2

[0039] An anti-off mechanism, including a block 12 that is rotatably connected to the notch 10 on the lifting lug, and also includes a locking block 11 that is rotatably connected to the notch 10 on the lifting lug, and the locking block 11 and the block 12 Locking connection, the locking block 11 includes a hook portion 13 and a force receiving portion 14, the block 12 includes a locking portion 15 and an anti-off portion 16, and the locking portion 15 is located in the notch 10 on the lifting lug Inside, the anti-off part 16 is located in the ear hole 1 of the lifting ear; the stopper 12 performs a pendulum movement, the stopper 12 swings clockwise and locks with the lock hook part 13 of the locking block 11, and the lock hook part 13 is in the lower position. In the pressed state, the block 12 swings counterclockwise to unlock the locking block 11, and the locking hook portion 13 is in a lifted state.

[0040] The locking block 11 and the blocking block 12 are in one-way lo...

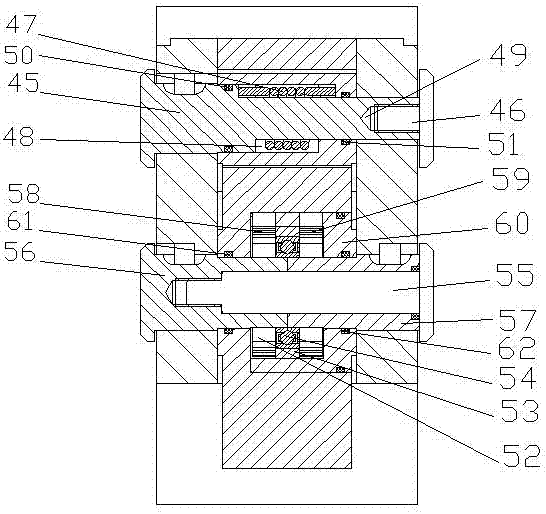

Embodiment 3

[0045] An anti-off mechanism, including a block 12 that is rotatably connected to the notch 10 on the lifting lug, and also includes a locking block 11 that is rotatably connected to the notch 10 on the lifting lug, and the locking block 11 and the block 12 Locking connection, the locking block 11 includes a hook portion 13 and a force receiving portion 14, the block 12 includes a locking portion 15 and an anti-off portion 16, and the locking portion 15 is located in the notch 10 on the lifting lug Inside, the anti-off part 16 is located in the ear hole 1 of the lifting ear; the stopper 12 performs a pendulum movement, the stopper 12 swings clockwise and locks with the lock hook part 13 of the locking block 11, and the lock hook part 13 is in the lower position. In the pressed state, the block 12 swings counterclockwise to unlock the locking block 11, and the locking hook portion 13 is in a lifted state.

[0046] The locking block 11 and the blocking block 12 are in one-way lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com