A hydraulic hammer control system

A technology of control system and hydraulic hammer, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motor components, etc., and can solve the problem of uneven wear of valve core and sleeve, complex oil circuit in separate installation, and poor oil flow. Small area and other problems, to improve hydraulic transmission efficiency, avoid uneven wear, and achieve the effect of large oil passage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

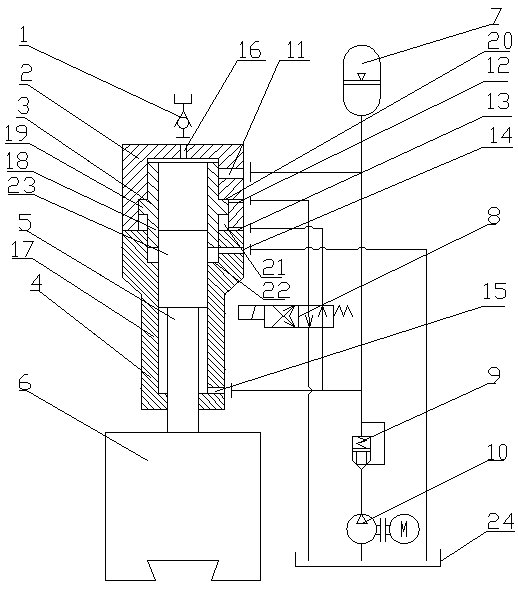

[0013] Such as figure 1 As shown, the hydraulic hammer control system includes a hydraulic cylinder 4, a hammer rod 5, a hammer head 6, a valve sleeve 2, and a cylindrical hydraulic valve core 3. The hydraulic cylinder 4 is a cylinder body 17 with an upper end opening, and the valve sleeve 2 is sealed and fixed on At the top of the cylinder block 17, the cylindrical hydraulic spool 3 is arranged in the valve sleeve 2 and the cylinder body 17. The cylindrical hydraulic spool 3 includes a cylindrical body 18 that penetrates up and down. The outer wall middle of the cylindrical body 18 is provided with an annular boss 19. A first step 20 is provided on the lower part of the inner side wall of the valve sleeve 2, and an annular groove 21 is formed between the lower step surface of the valve sleeve 2 and the top end of the hydraulic cylinder block 17, and the annular boss 19 fits in the annular groove 21. The inner side wall of the upper part of 17 is provided with a second step 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com