Load locking and adjusting improved constant force spring support hanging bracket

A constant force spring and improved technology, applied in the field of supports and hangers, can solve the problems of difficult concentricity, small output load adjustment range, fracture and other problems, and achieve the effects of large load adjustment range, convenient load adjustment and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

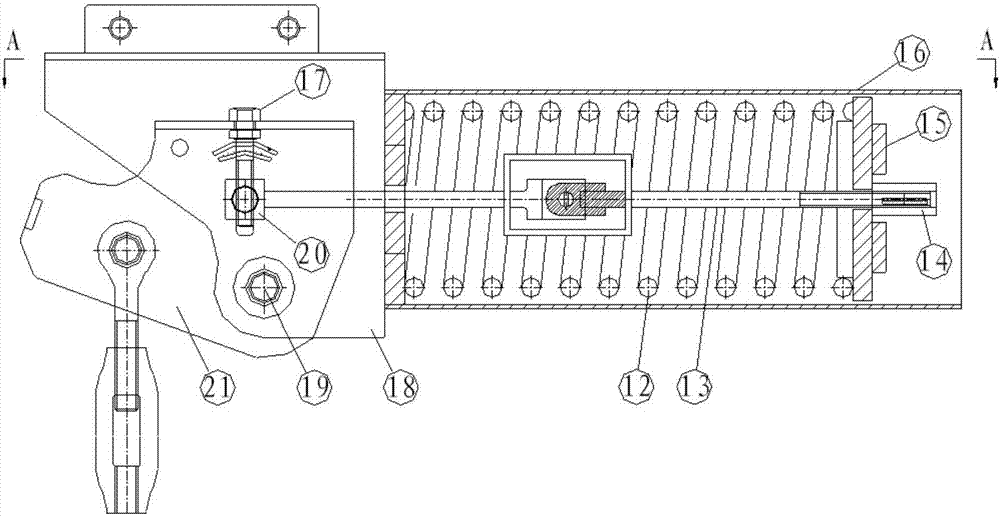

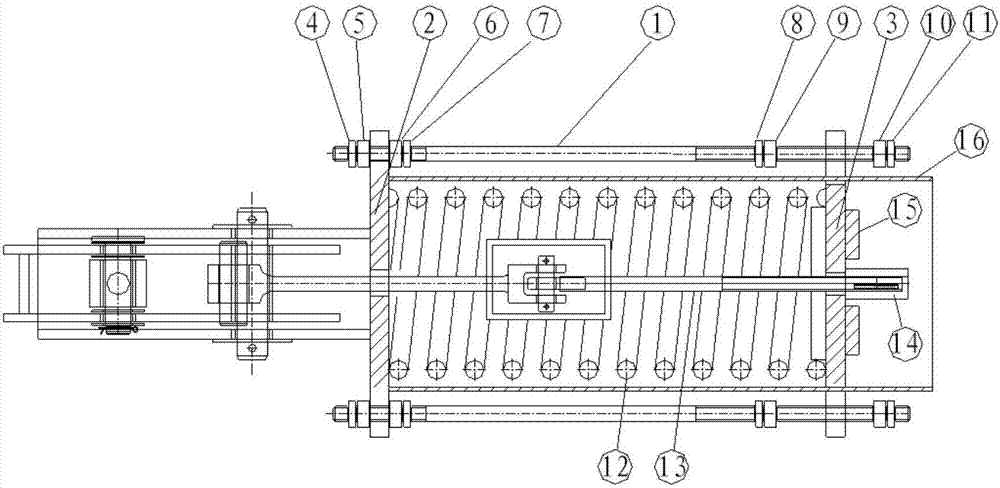

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

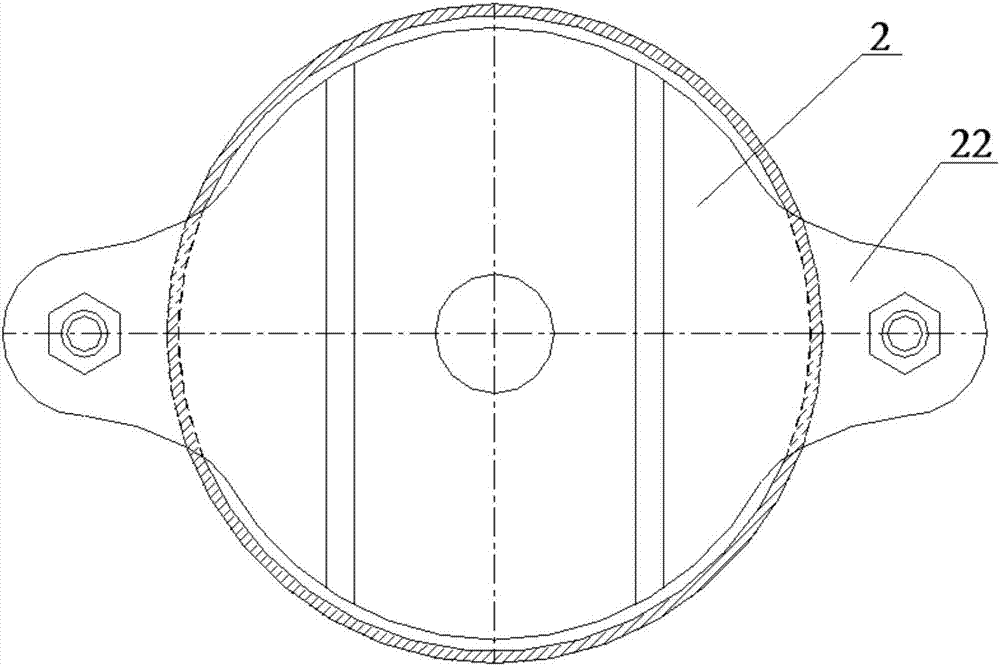

[0023] refer to figure 1 , the load locking and adjustment improved constant force spring support and hanger of the present invention includes a front end plate 2, a spring cover tube 16, an outer frame 18, a revolving frame 21, a pull rod 1, a main shaft 19, a tail end plate 3, a spring Pull rod 13, guide sleeve 20 and load adjustment nut 14; one side of the front end plate 2 is fixed on the end face of one end of the spring cover tube 16, the outer frame 18 is fixed on the other side of the front end plate 2, and the rotary frame 21 The end of the shaft is located in the outer frame 18, the main shaft 19 passes through the outer frame 18 and the revolving frame 21 to connect the outer frame 18 with the revolving frame 21, the tail end plate 3 is located in the other end of the spring cover tube 16, and the spring cover tube 16 A spring 12 is provided, and one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com