Patents

Literature

30results about How to "Easy load adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

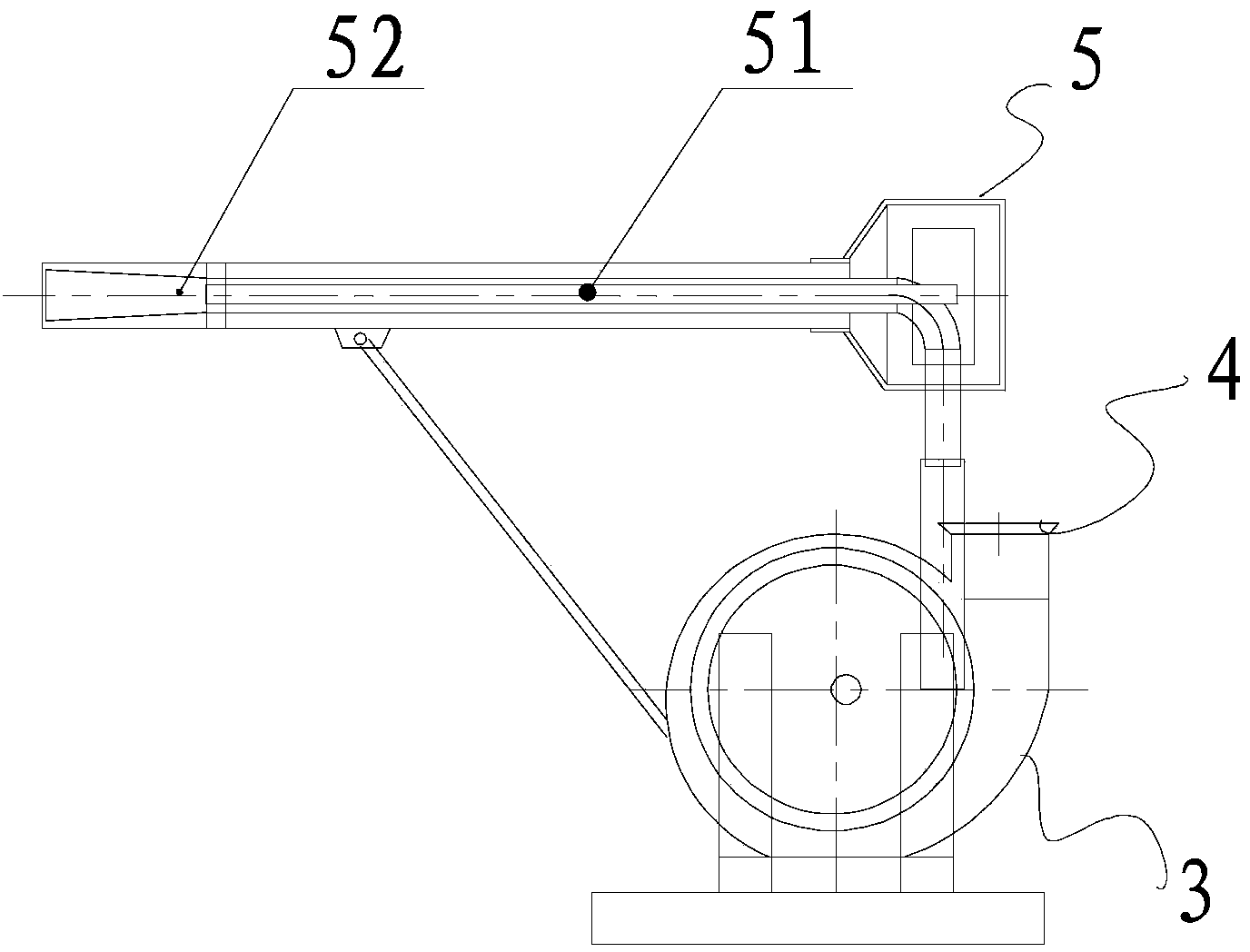

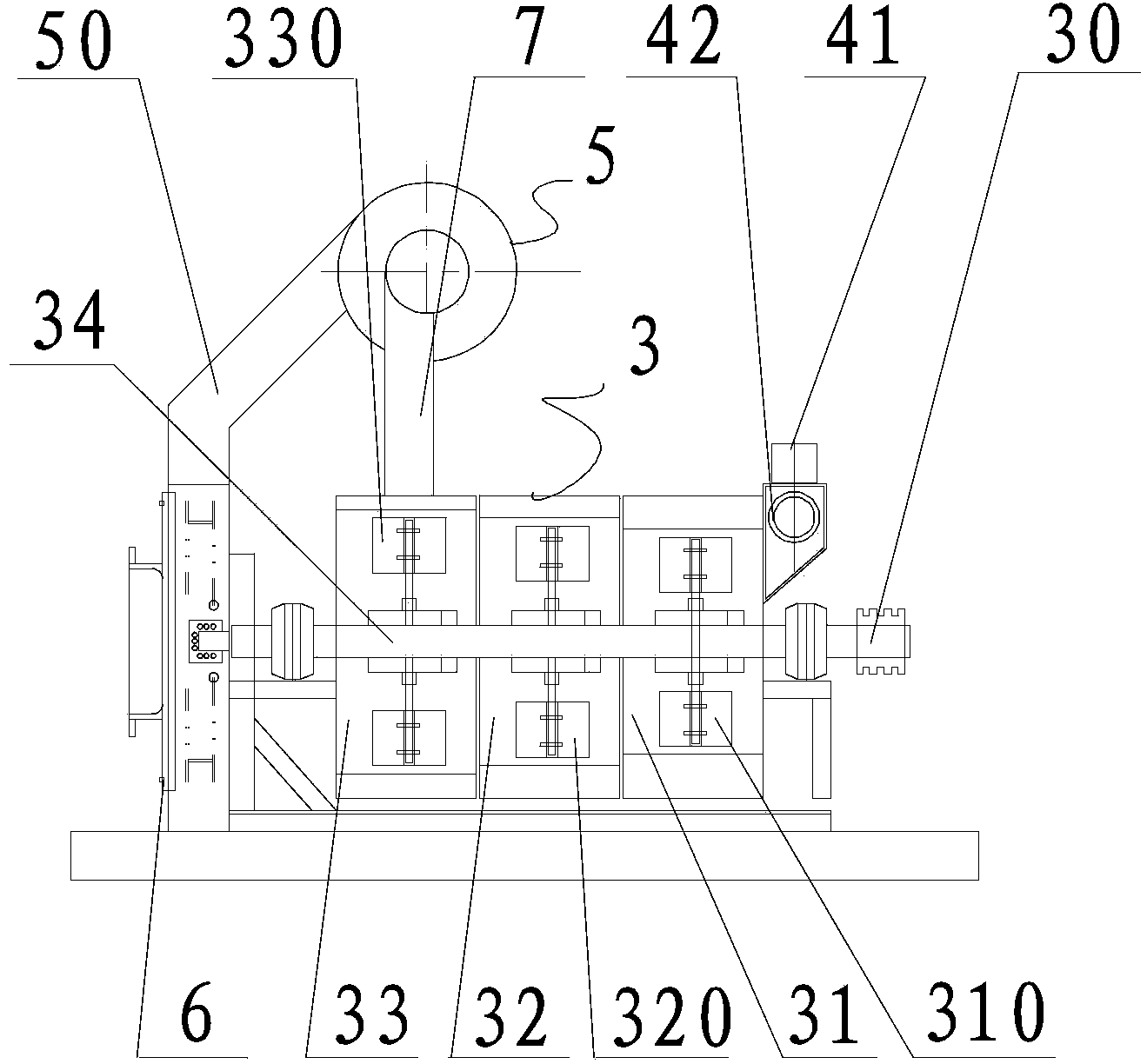

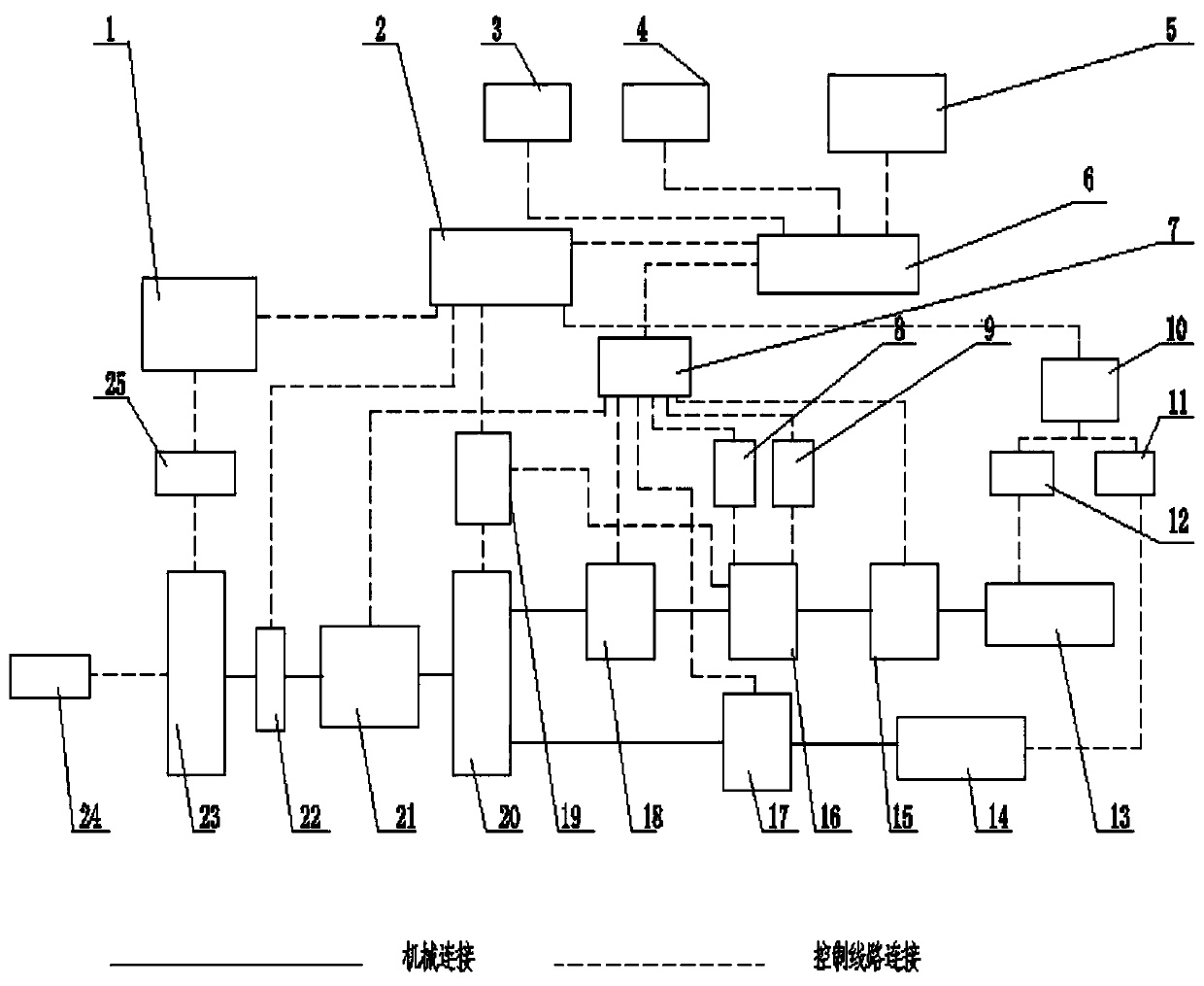

Novel fitness load mode and fitness load device thereof

InactiveCN110270048AEasy load adjustmentSmall footprintMuscle exercising devicesCountermeasureUnit device

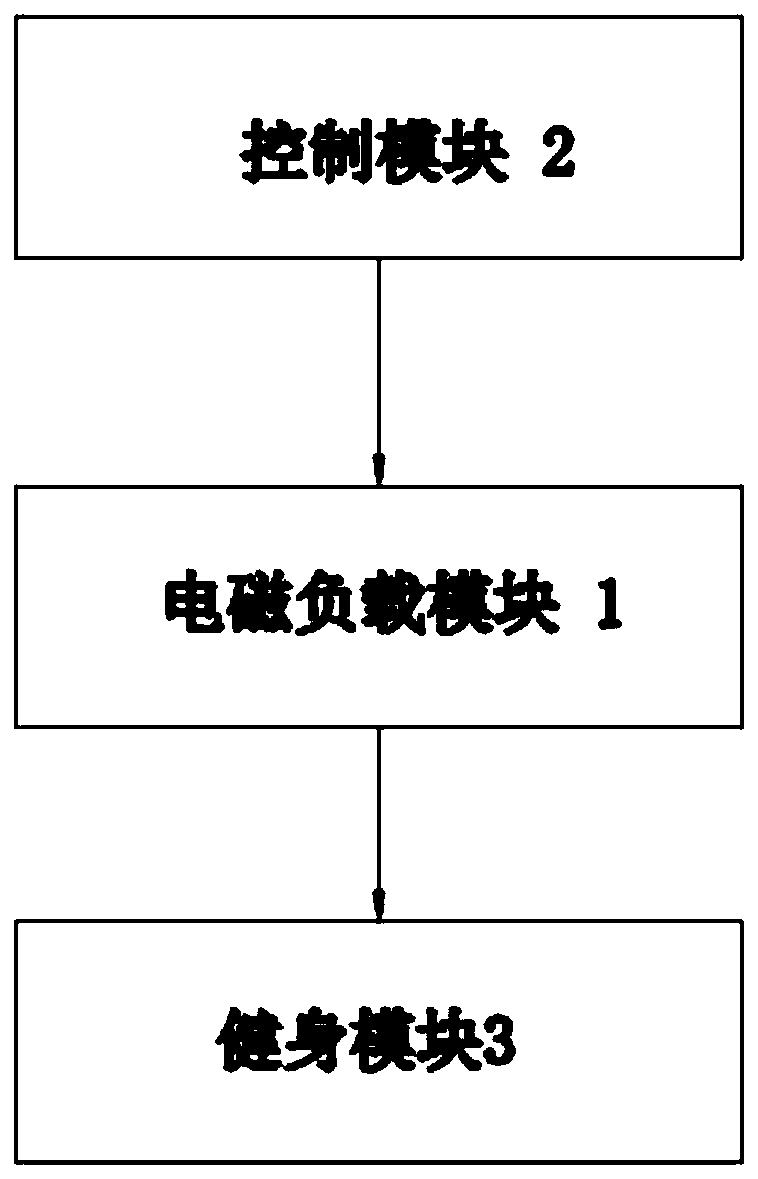

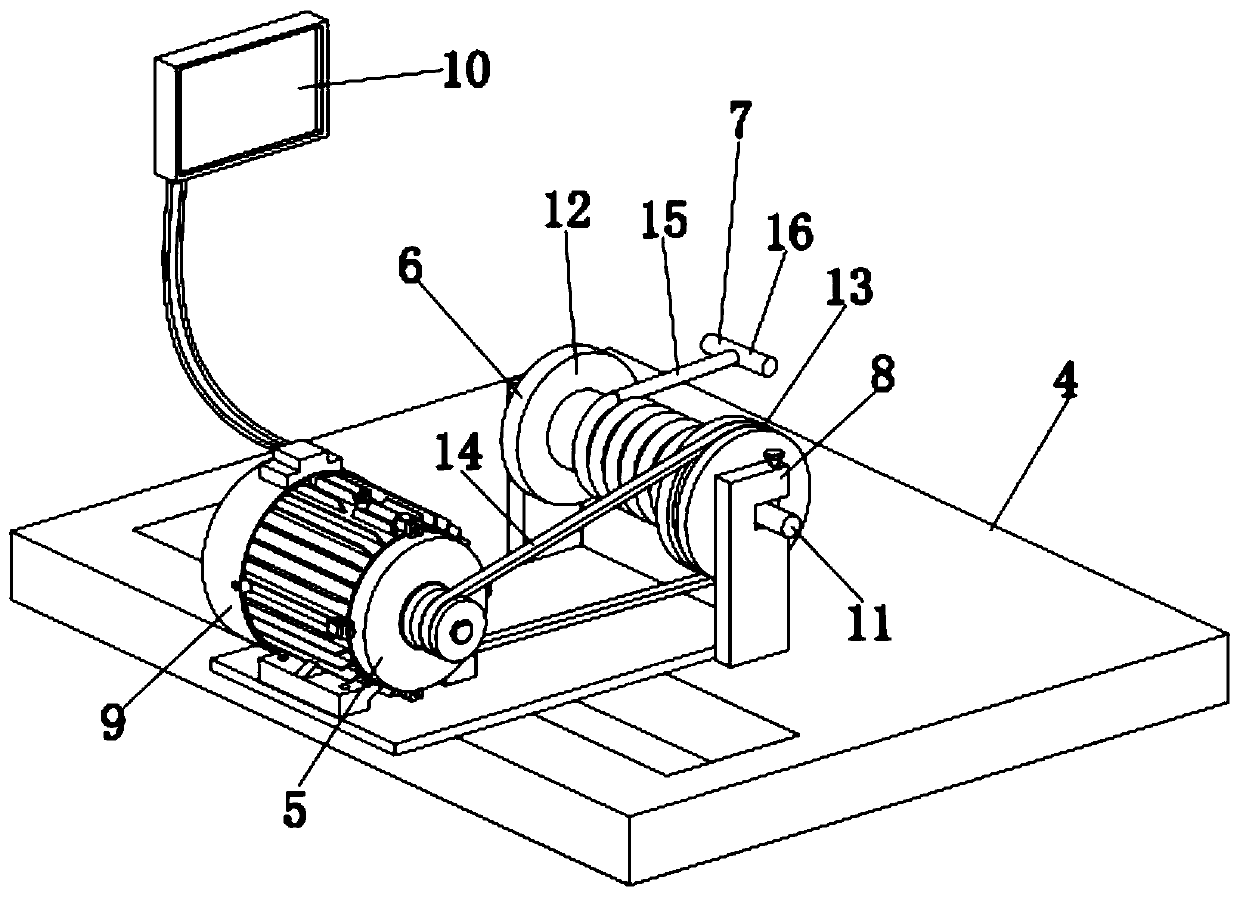

The invention discloses a novel fitness load mode and a fitness load device thereof, and relates to the technical field of fitness equipment. The novel fitness load mode comprises: an electromagnetic load module, which is used for providing load force; a control module, which is connected with the electromagnetic load module and which is used for controlling the power of the electromagnetic load module according to the requirements of a trainee so as to control the magnitude of the load force and also used for displaying consumed heat and recording exercise time and stretching times; and a fitness module, which is connected with the electromagnetic load module and which is used for the trainee to carry out fitness training against the load force of the electromagnetic load module. By the adoption of the technical scheme, countermeasure fitness training in a weight mode can be avoided, and the novel fitness load mode has the advantages of being convenient in load force adjustment, small in occupied space and high in safety coefficient.

Owner:SHENZHEN RUOTENG TECH CO LTD

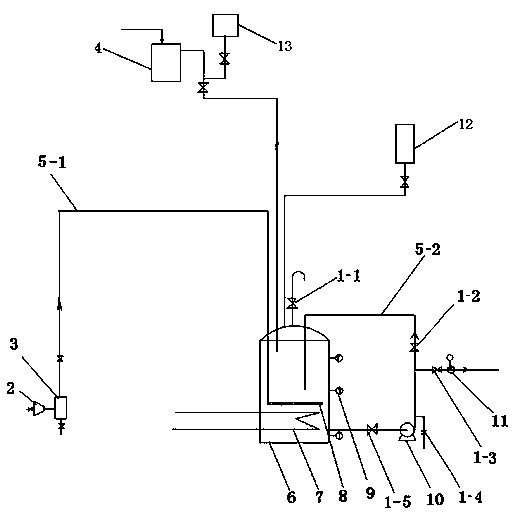

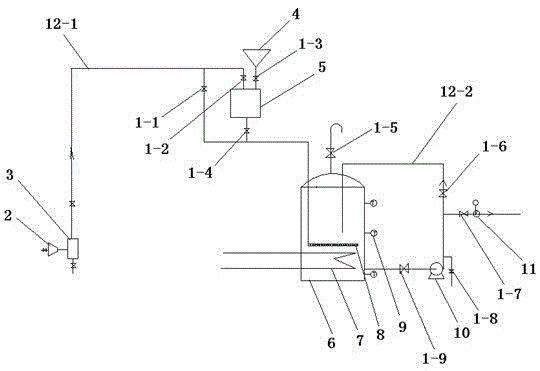

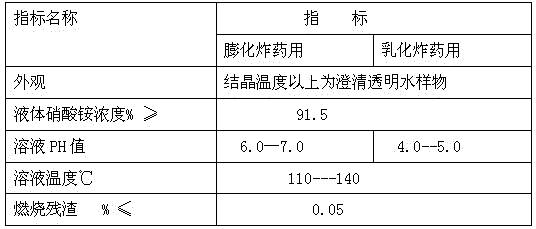

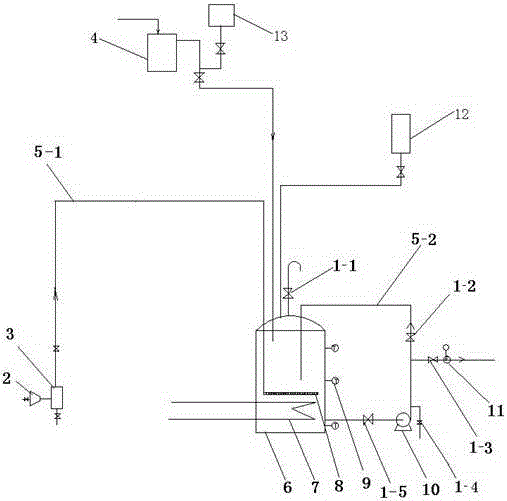

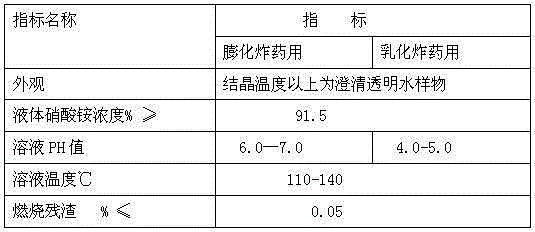

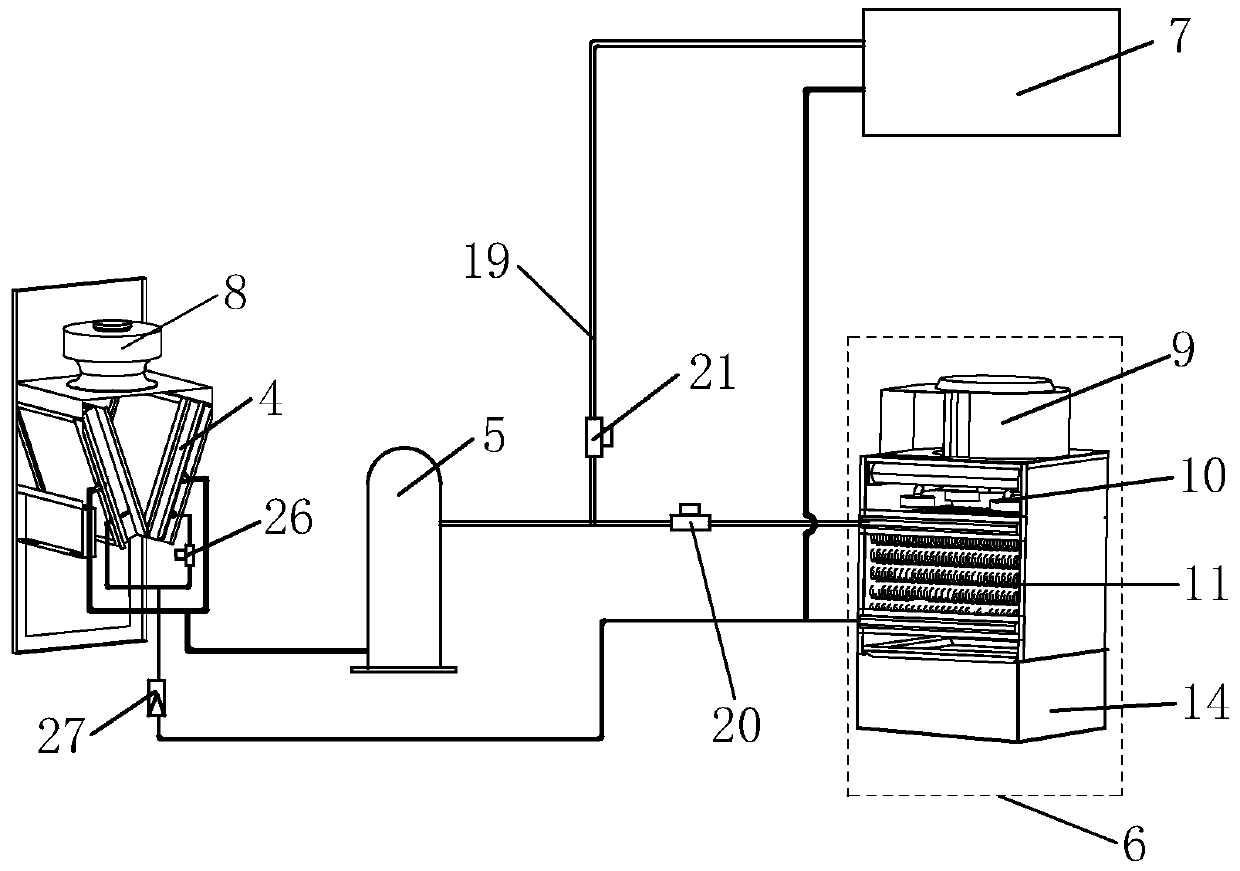

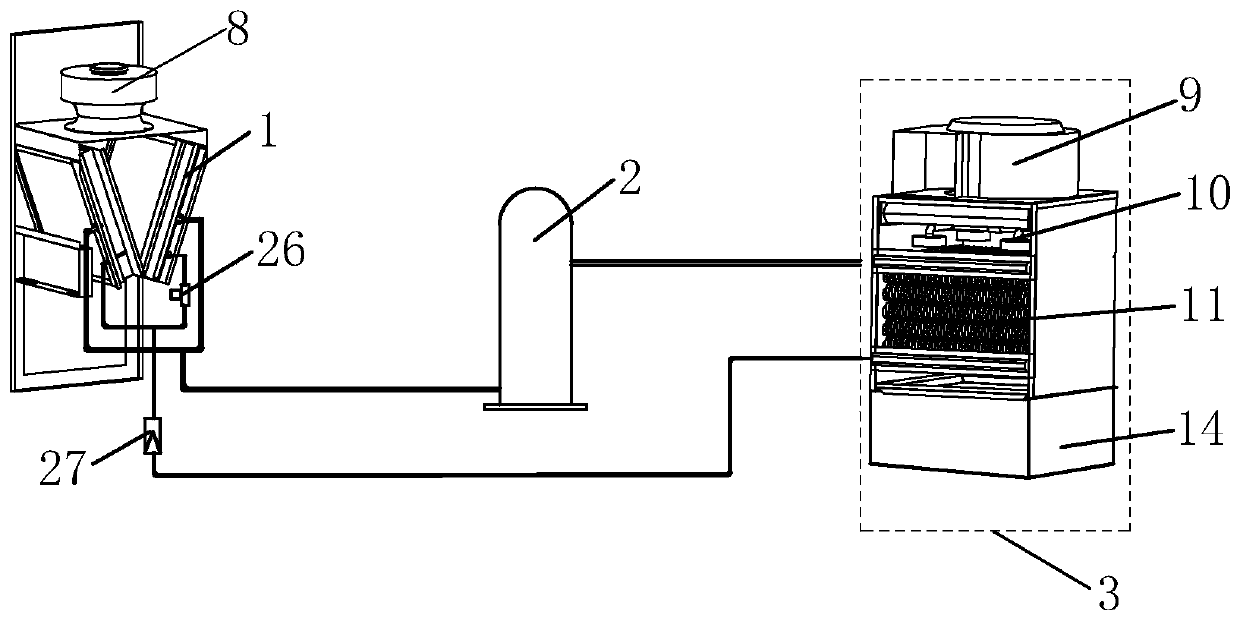

Finished product ammonium nitrate aqueous solution pH value controlling method and device thereof

InactiveCN103497078APH value quickly reaches the standardControl PH valueExplosivesAir compressorAqueous solution

The invention provides a finished product ammonium nitrate aqueous solution pH value controlling method comprising the steps that: temperature and pressure of ammonium nitrate aqueous solution in a storage tank are adjusted; compressed air stirring is carried out; self circulation mixing is carried out by using a circulation conveyor pump; and acid liquid or alkali liquid is added according to the calculation of pH value, such that pH value is adjusted. The invention also provides a controlling device comprising the storage tank. An air distributor is horizontally arranged in the middle in the storage tank. The air distributor is connected with an air compressor arranged outside the storage tank through a first pipe. An acid / alkali tank used for adjusting the pH value is connected in the first pipe. The circulation conveyor pump is connected at an outlet end on the bottom of the storage tank. The outlet end of the circulation conveyor pump communicates with the upper end of the storage tank through a second pipe. The outlet end of the second pipe is positioned at the middle-upper part of the storage tank. With the method and the device provided by the invention, ammonium nitrate aqueous solution pH value can be precisely and rapidly controlled, such that application requirement can be satisfied, and safety during the application process can be ensured.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

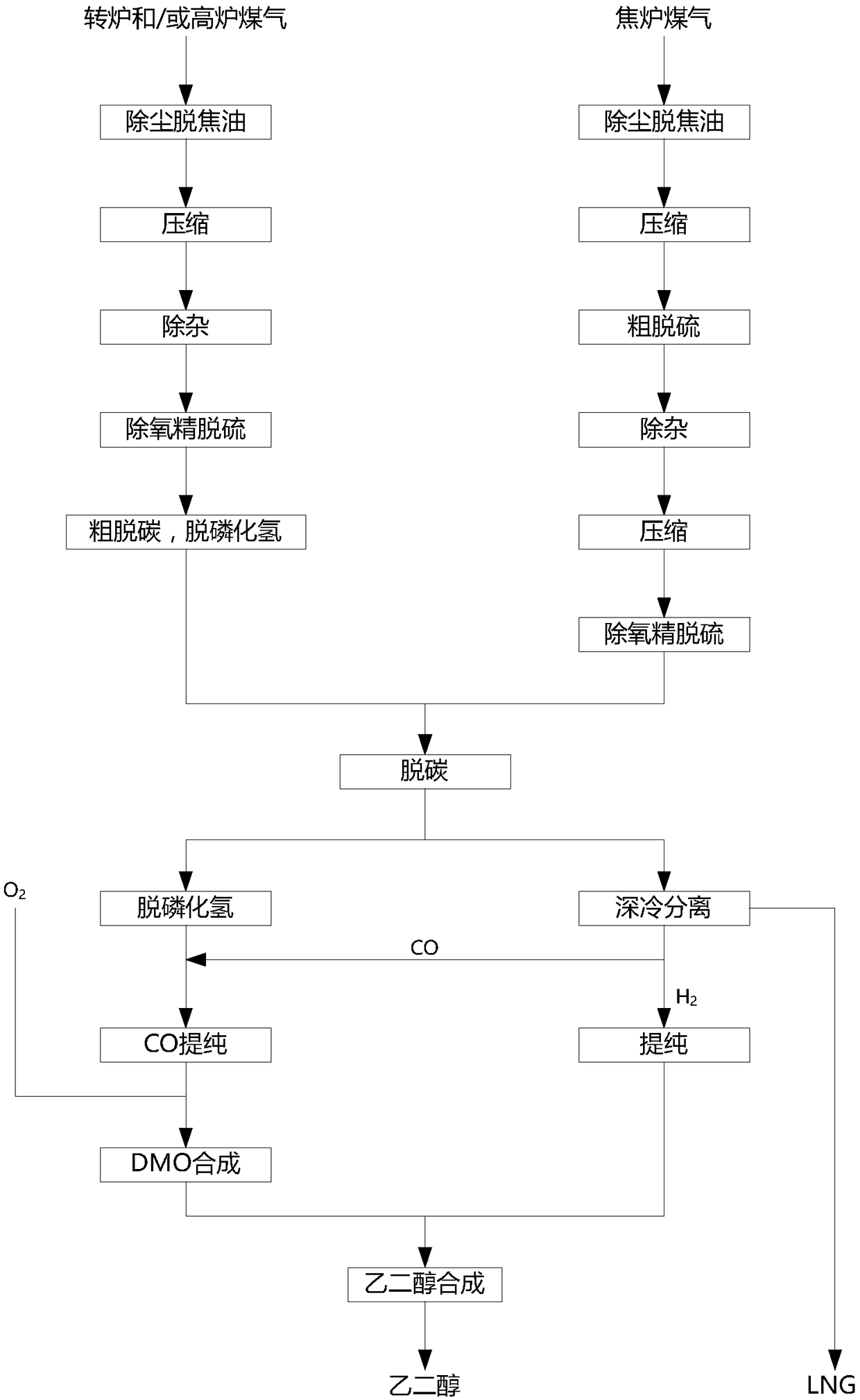

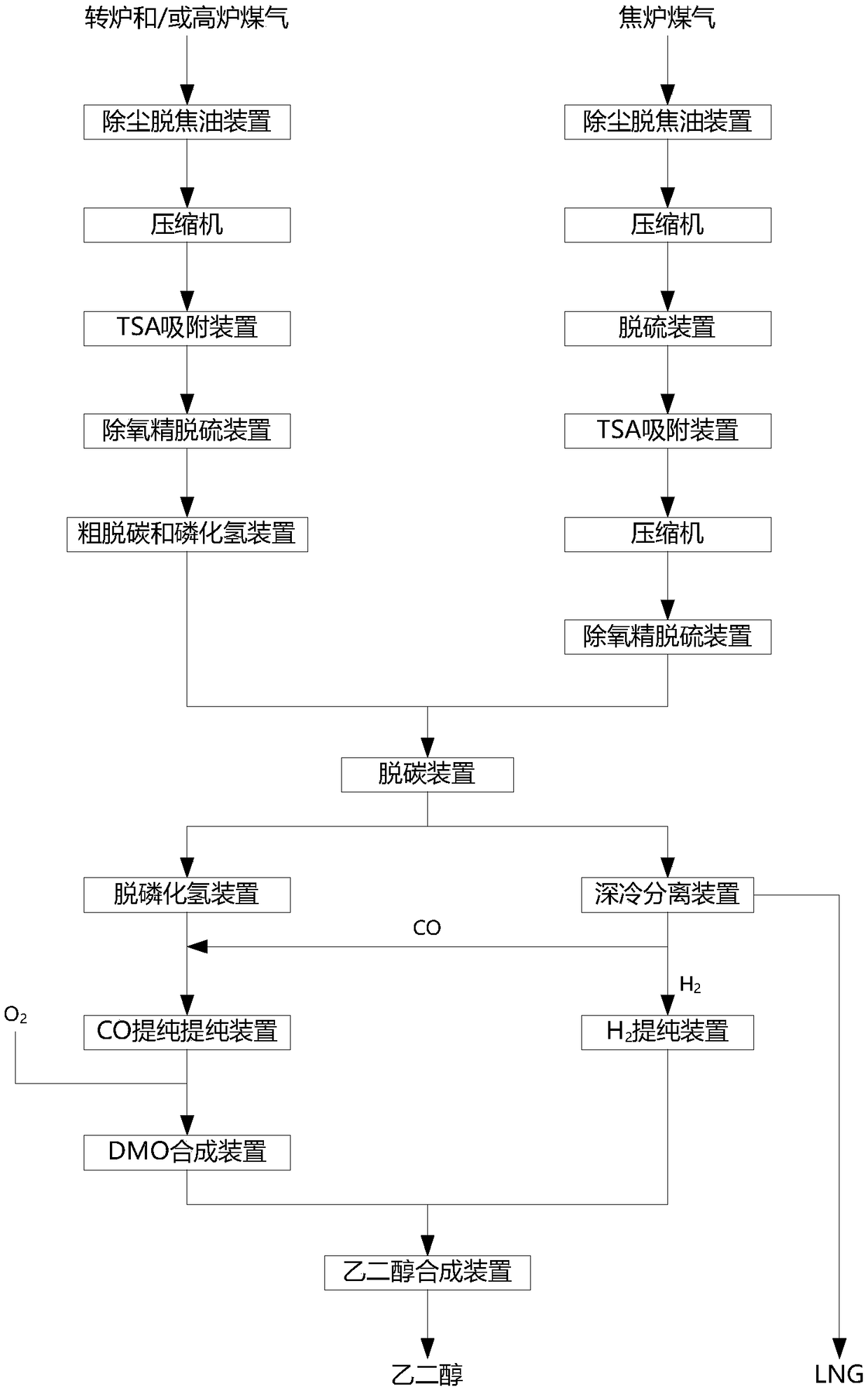

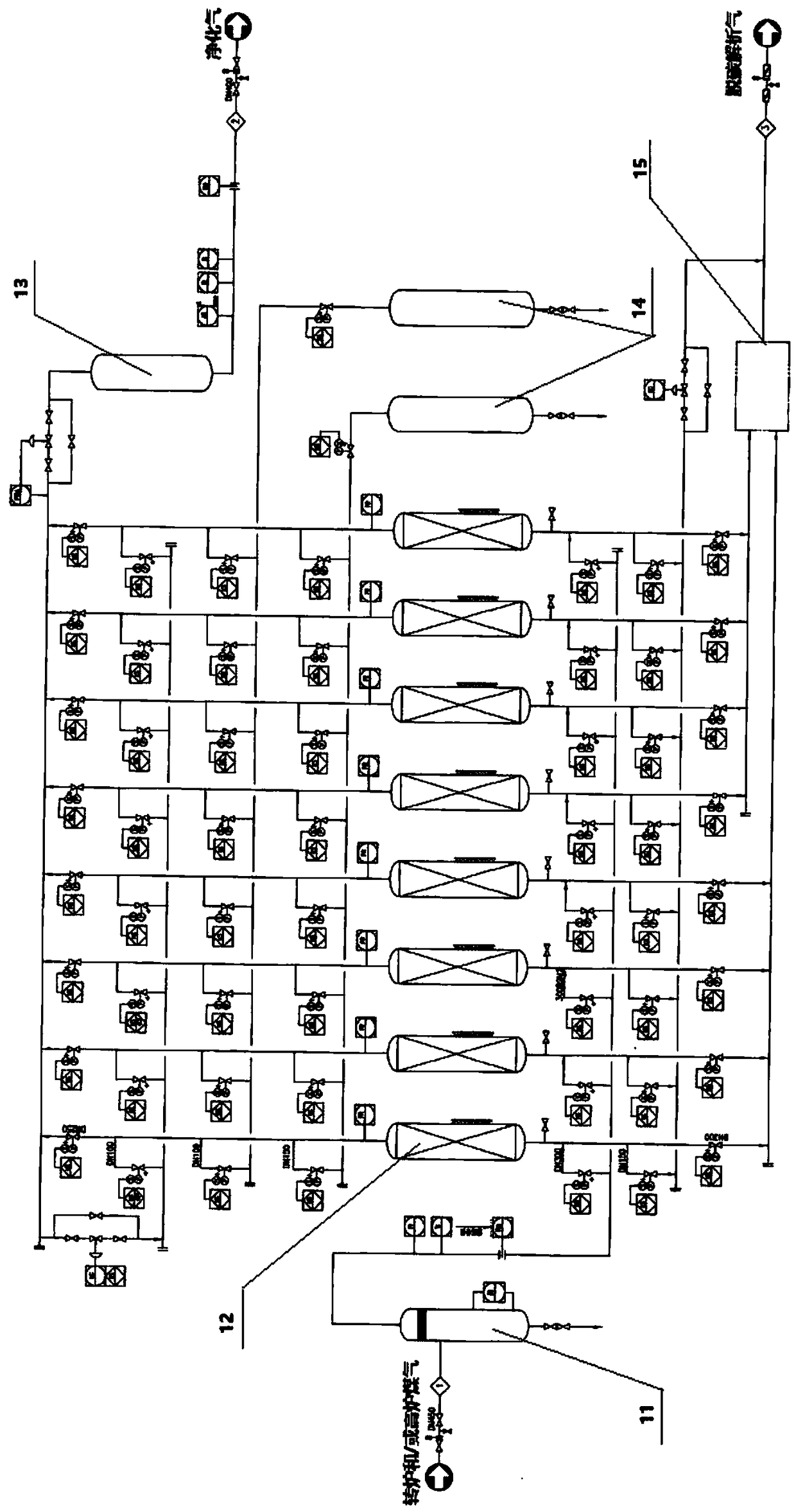

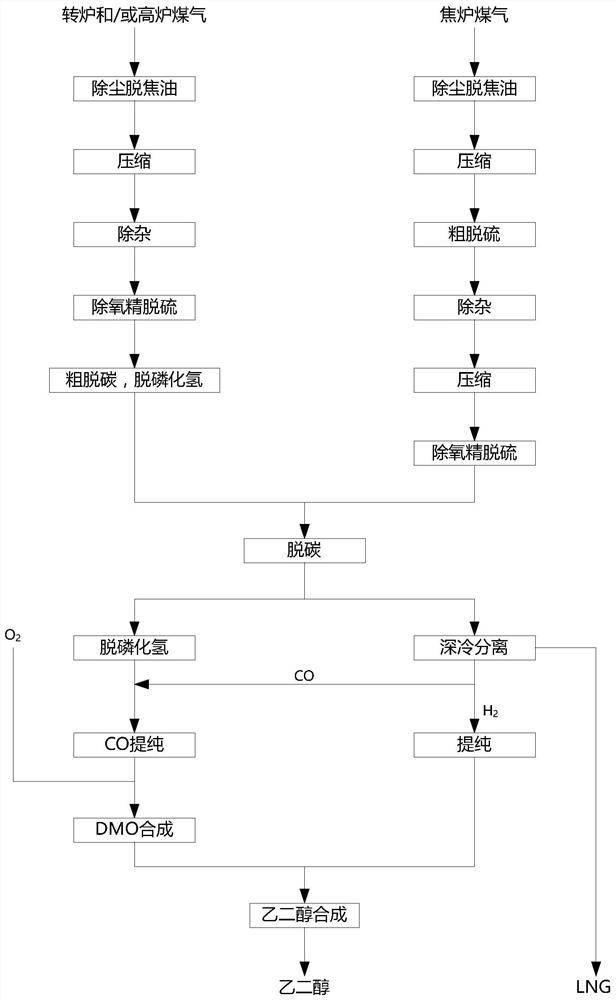

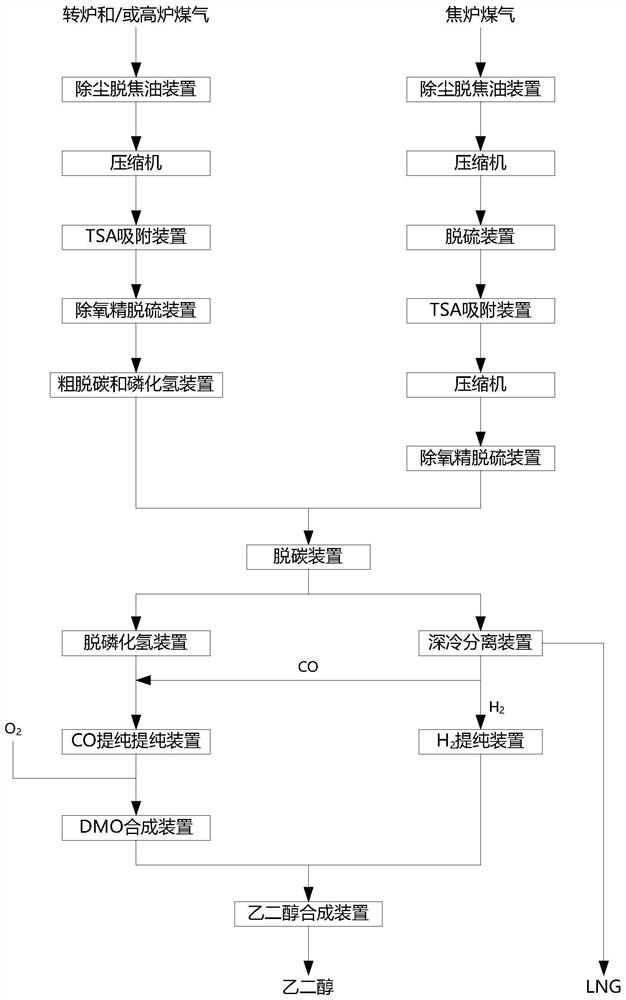

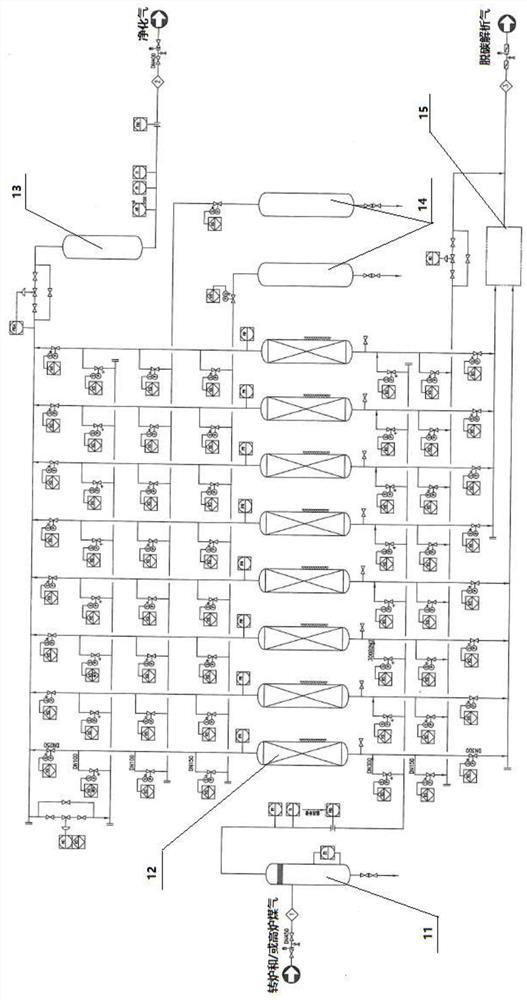

Method for synthesis of glycol and co-production of LNG by using coke oven gas and converter and/or blast-furnace gas

ActiveCN109111341AFull and efficient useReduce wasteOrganic compound preparationGaseous fuelsHydrogenTar

The invention relates to a method for synthesis of glycol and co-production of LNG by using coke oven gas and converter and / or blast-furnace gas, belonging to the technical field of chemical engineering. According to a technical scheme in the invention, the method comprises the following steps: subjecting coke oven gas to dust removal and tar removal treatment, and then performing compression treatment, and then performing crude desulfurization; removing impurities in the coke oven gas having undergone desulfurization treatment; subjecting the gas having undergone impurity removal to compression, fine desulfurization and O2 removal; then removing CO2 gas in the gas by using an amine process; carrying out cryogenic separation to obtain the product LNG, separating H2 and CO-rich gas at the same time, and then purifying H2; then subjecting converter and blast-furnace gas to dust removal and tar removal treatment; then carrying out compression and impurity removal, subjecting the gas having undergone impurity removal to fine desulfurization and O2 removal, and then removing CO2 gas in the gas; and combining the purified gas with the CO-rich gas, purifying the CO gas, subjecting the purified CO to esterification-carbonylation cyclic synthesis to produce DMO, and producing glycol from DMO and purified hydrogen. The method of the invention is applied to the synthesis technology of glycol for the first time.

Owner:戴乐亭 +3

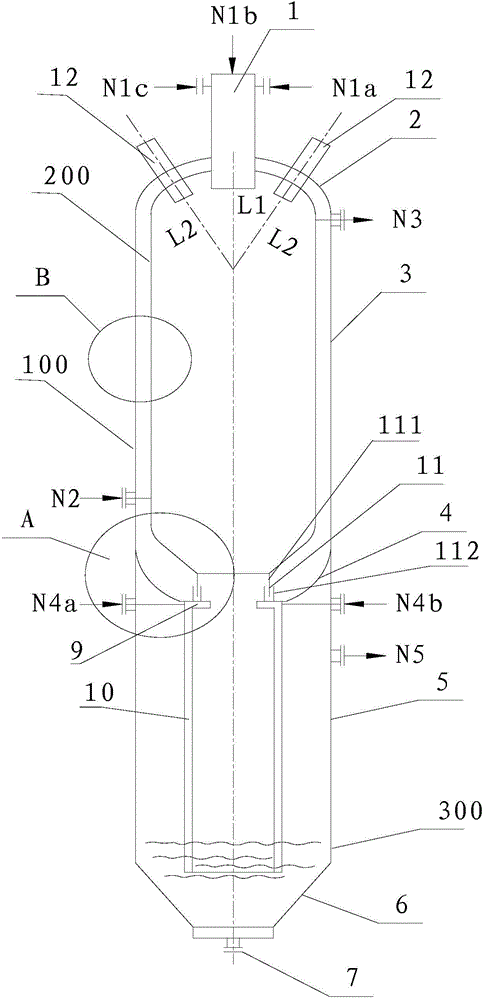

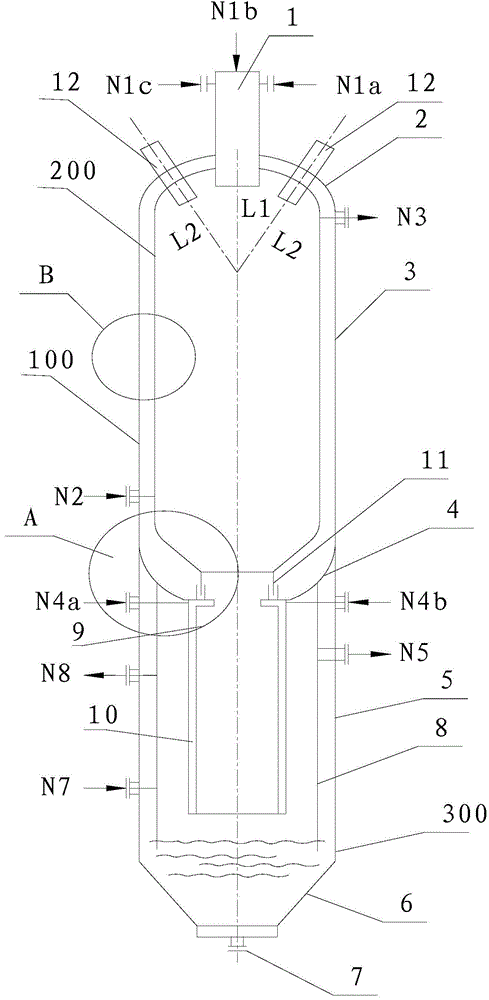

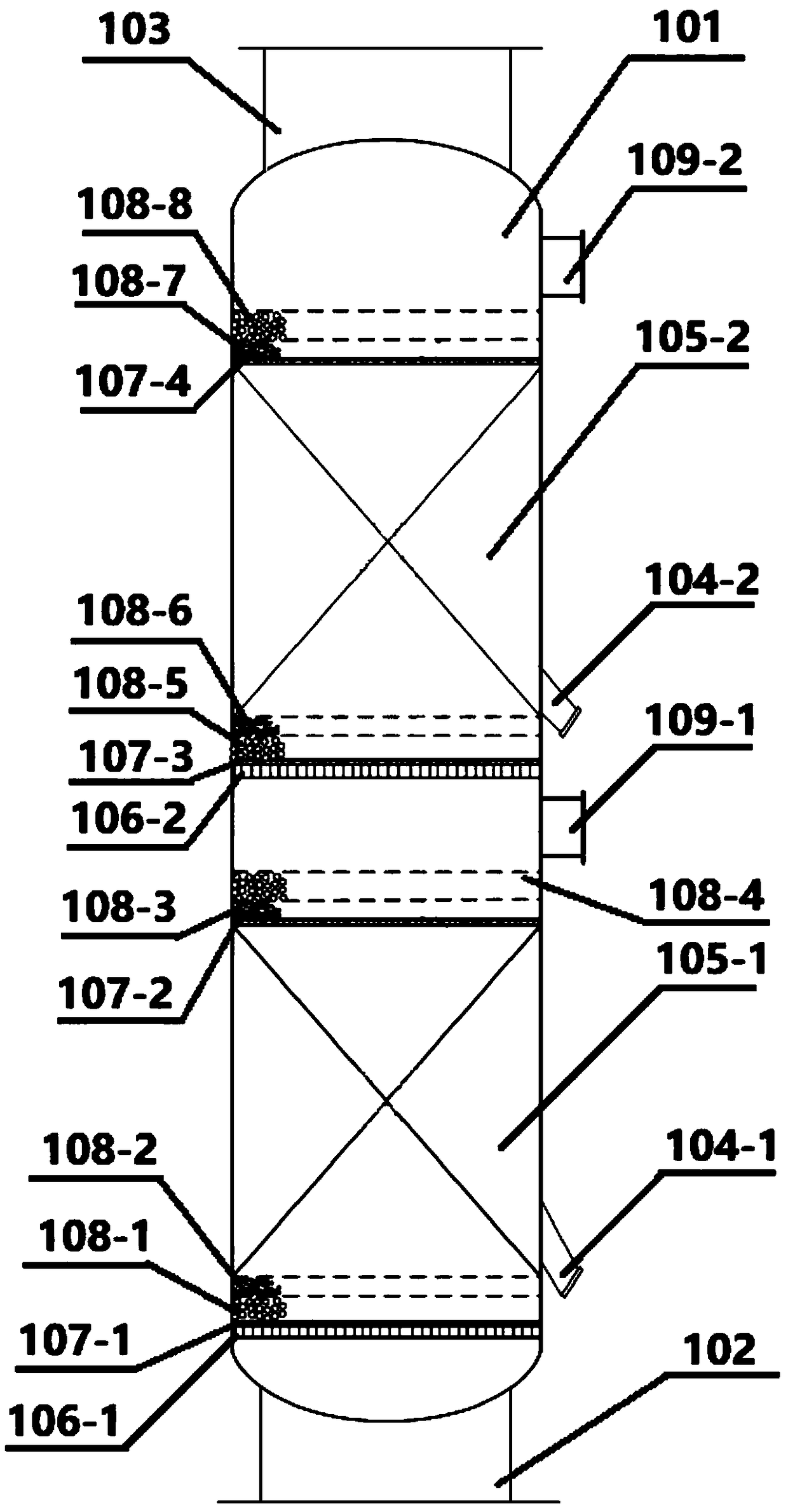

Overhead multi-nozzle gasifier

ActiveCN104312633AWell mixedEasy load adjustmentGasification apparatus detailsGranular/pulverulent flues gasificationRetention timeLoad regulation

The invention discloses an overhead multi-nozzle gasifier. The overhead multi-nozzle gasifier comprises an outer shell, an inner shell, a main nozzle, a plurality of auxiliary nozzles, a first conveying device, a second conveying device, a lower shell and coolers, wherein the main nozzle is a firing-up and technological operation combined nozzle or a firing-up nozzle and is vertically arranged at the tops of the outer and inner shells; each auxiliary nozzle is a technological operation nozzle and is obliquely arranged at the tops of the outer and inner shells; a central extension line of an outlet of each auxiliary nozzle and a central extension line of an outlet of the main nozzle intersect at a point in a gasification chamber; the first conveying device is connected with the main nozzle; the second conveying device is connected with the auxiliary nozzles. The overhead multi-nozzle gasifier disclosed by the embodiment of the invention has the advantages of good material mixing, long material retention time, high carbon conversion rate, high processing capacity, convenience in load regulation, long service life, and the like.

Owner:TSINGHUA UNIV

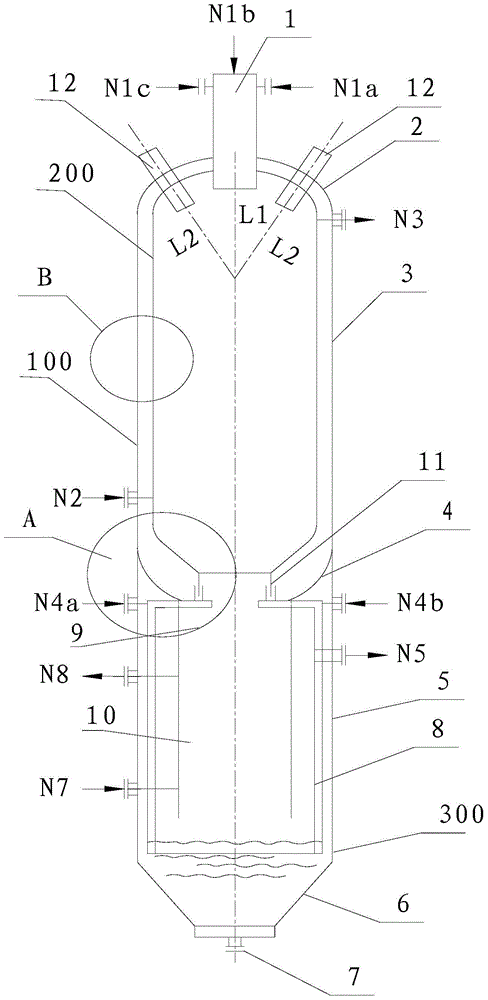

Efficient steam boiler for gasification and combined combustion of pulverized coal

ActiveCN102818247AImprove combustion efficiency and thermal efficiencySave spaceEnergy inputSteam boilersFlueSuperheater

The invention discloses an efficient steam boiler for gasification and combined combustion of pulverized coal, comprising a blast blower, a pulverized coal bunker, a pulverized coal transmission pipe, a combustion chamber, a gasification chamber, a hearth, a horizontal flue, a steam superheater, a tail shaft and a boiler support, wherein the blast blower is connected with the pulverized coal bunker, and connected with the gasification chamber through the pulverized coal transmission pipe; a combustor is connected with the gasification chamber; the gasification chamber, the hearth, the horizontal flue and the tail shaft are connected in order, and arranged on the boiler support to form an inversed U shape; a non-combustion zone is arranged above the joint of the hearth and the gasification chamber; the hearth is provided with a jet flow air inlet and a secondary air inlet at the bottom; the outlet of the non-combustion zone is provided with a tertiary air inlet; the steam superheater is arranged in the horizontal flue; and the tail shaft is internally provided with a coal economizer and an air preheater. The efficient steam boiler for gasification and combined combustion of pulverized coal disclosed by the invention saves space, reduces dust emission, realizes gasified transmission, and stabilizes combustion; and the burn-off rate of the pulverized coal is above 99%, and the heat efficiency is above 93%.

Owner:青岛青义锅炉有限公司

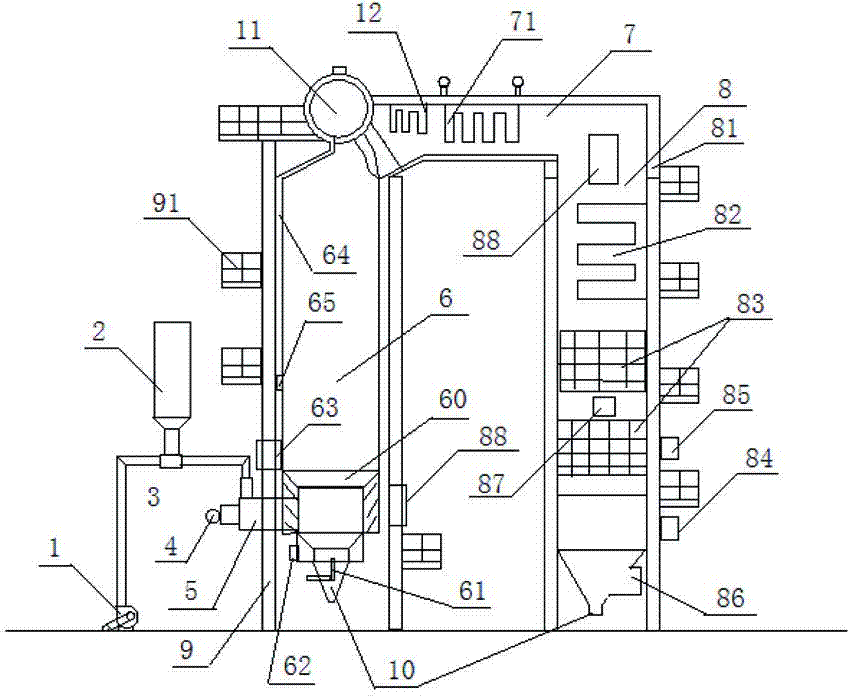

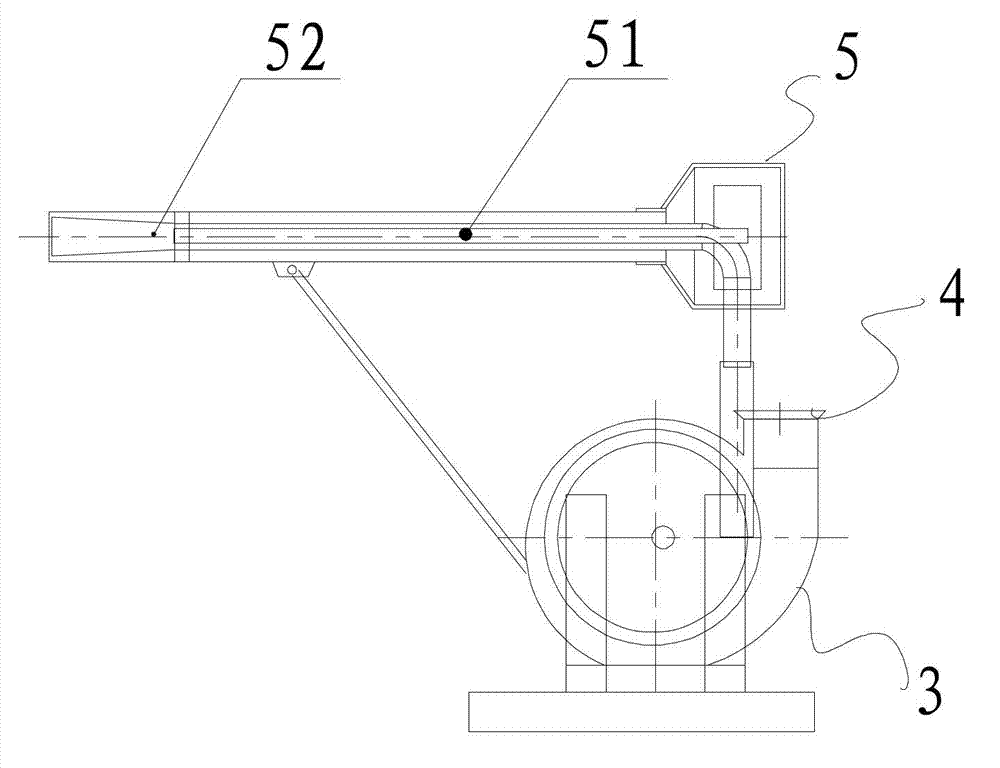

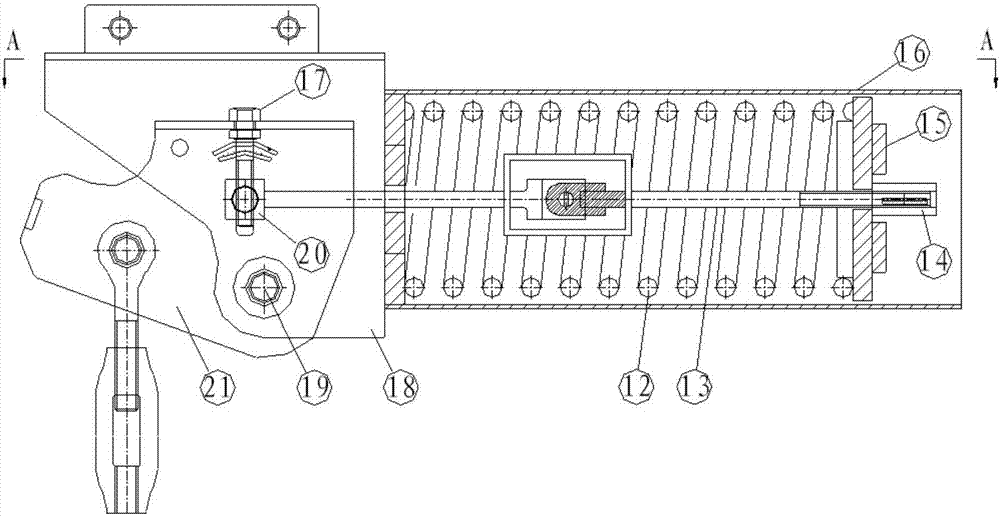

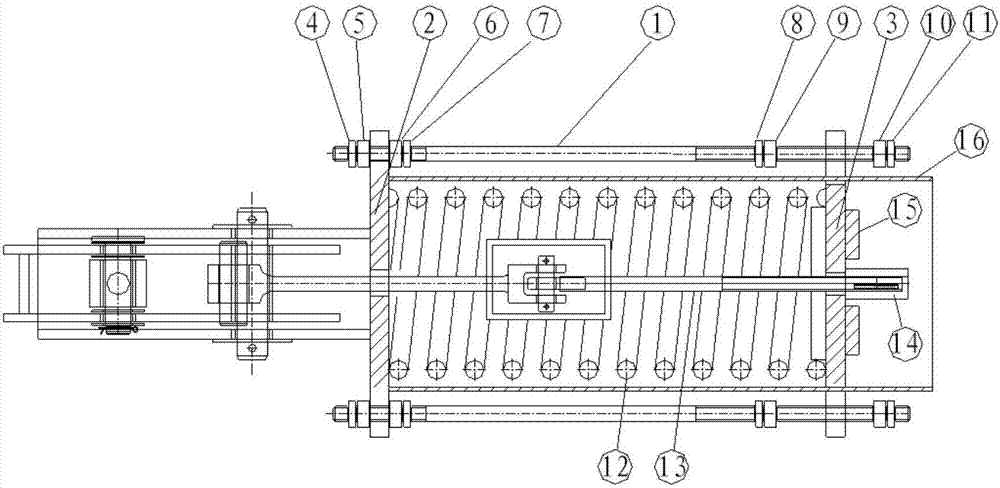

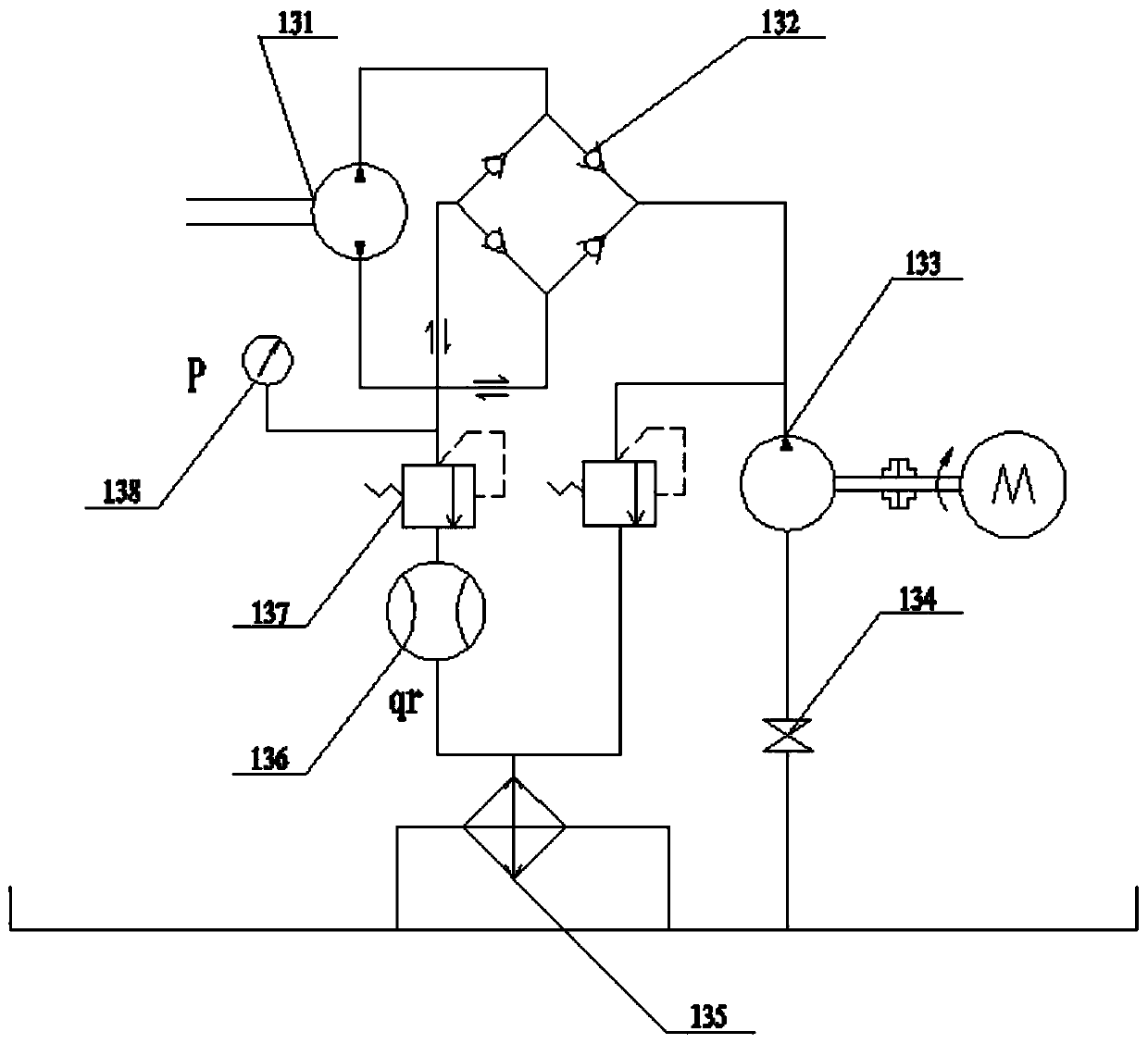

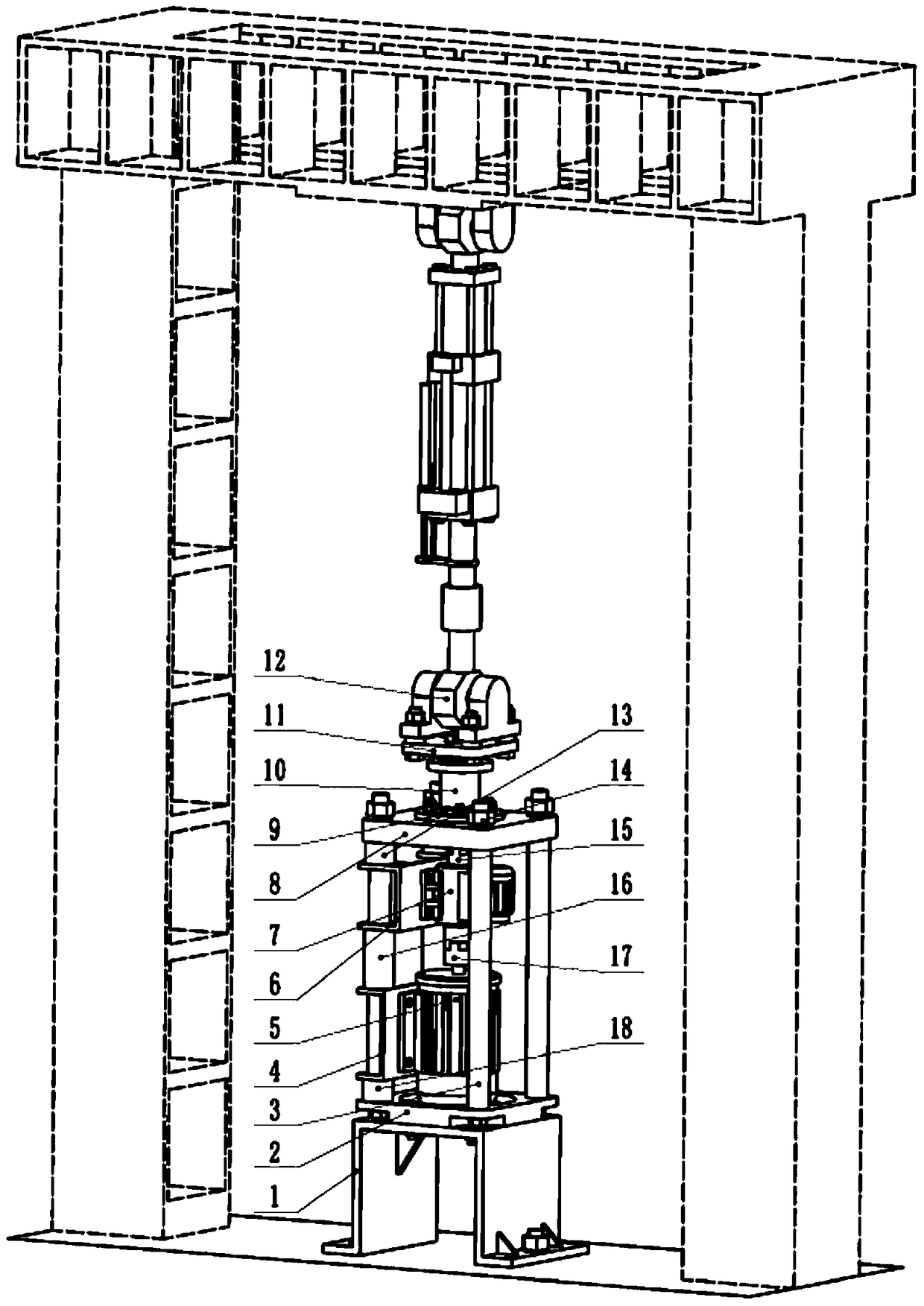

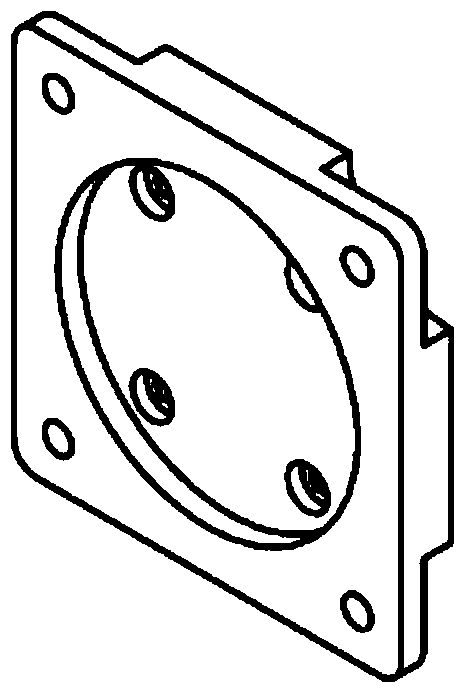

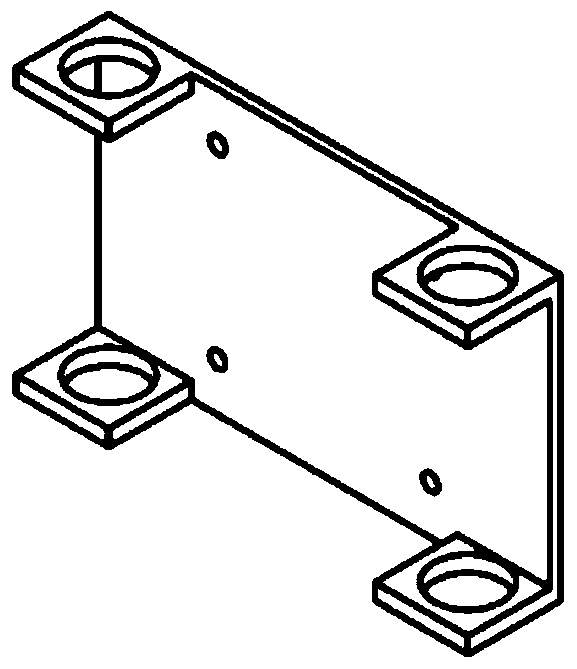

Ball screw servo loading test device based on hydraulic servo system

InactiveCN104931253AEasy load adjustmentRealize working condition simulationMachine gearing/transmission testingServo actuatorBall screw

The invention discloses a ball screw servo loading test device based on a hydraulic servo system. The whole device has a vertical structure. A landing base is fixed on a pedestal or the ground, and a bottom plate is fixed on the landing base. Four supporting steel pipes are vertically fixed in the four corners of the bottom plate. An installing base is fixed at the upper ends of the four supporting steel pipes. A motor and a rotating speed torque sensor are installed on two of the supporting steel pipes. A rotating speed torque sensor shaft is respectively connected with a motor and a ball screw shaft. The nut of a ball screw is fixedly connected with a nut sleeve. The nut sleeve is installed in a rotation-limiting supporting base. The nut sleeve is connected with an electro-hydraulic servo actuator via an actuator connection plate. Active loading can be performed on the ball screw so that load adjustment is convenient, simulation of the working conditions of varied loads can be realized, the loads can be displayed and controlled in real time, and performance testing of the ball screw can also be performed.

Owner:NANJING UNIV OF SCI & TECH

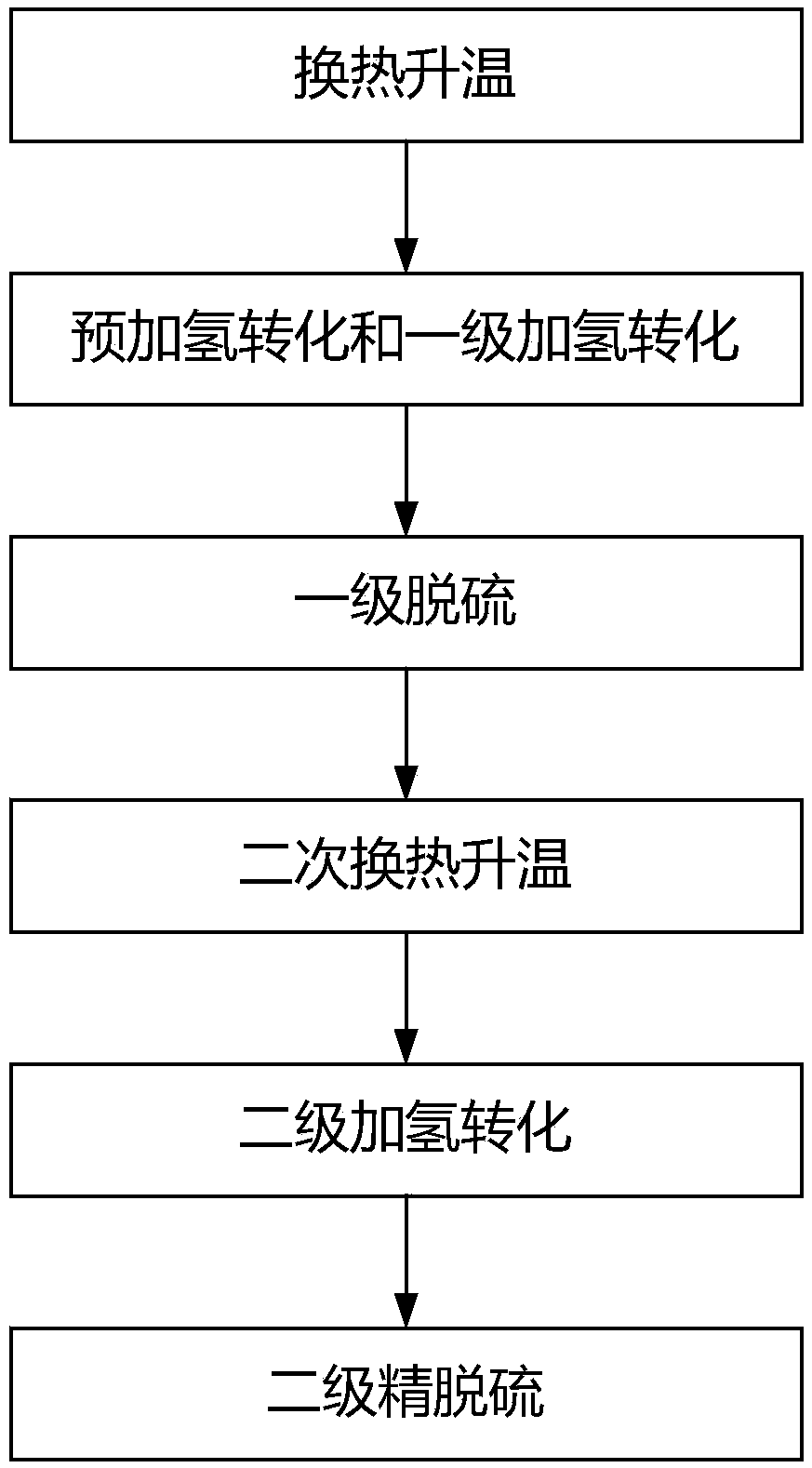

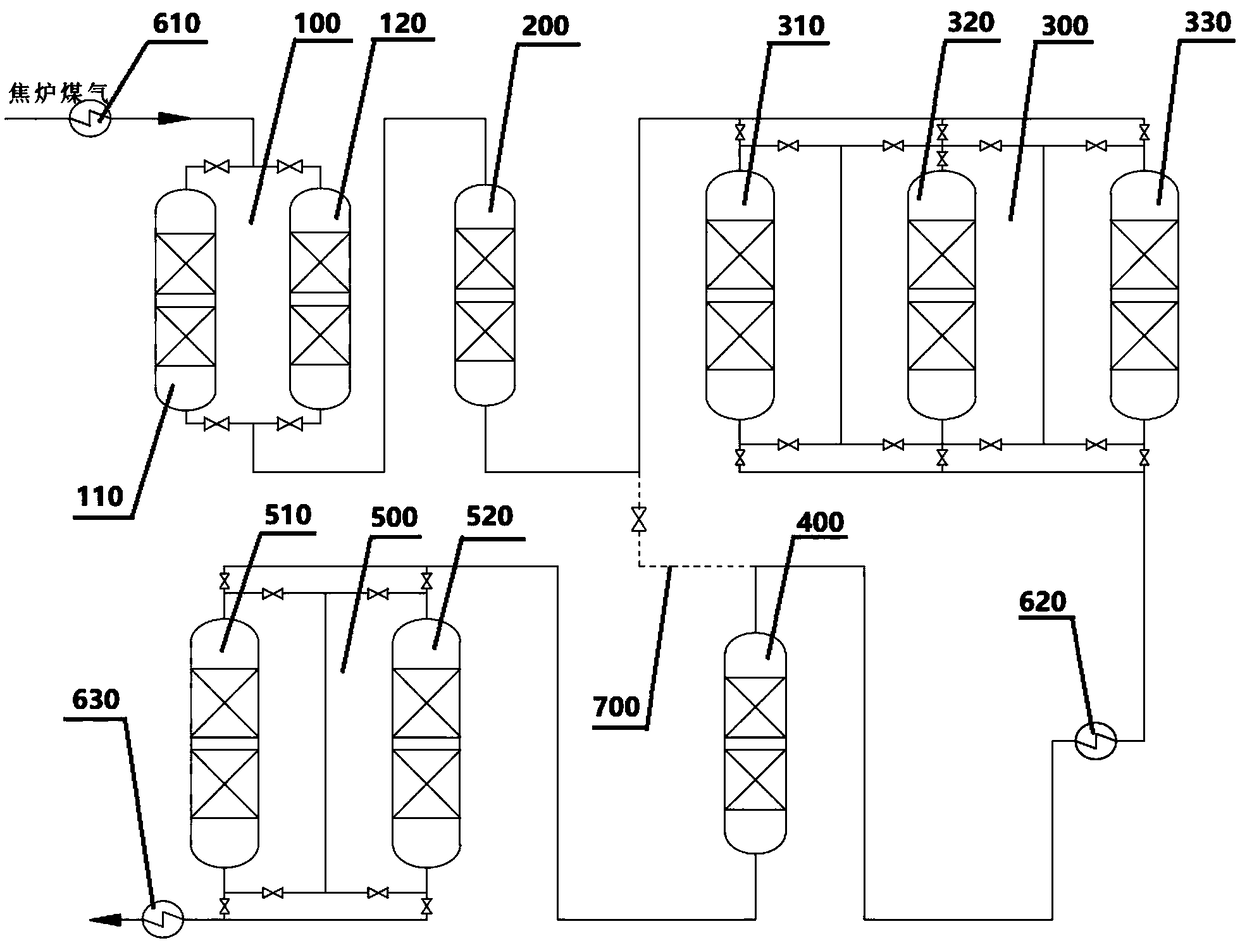

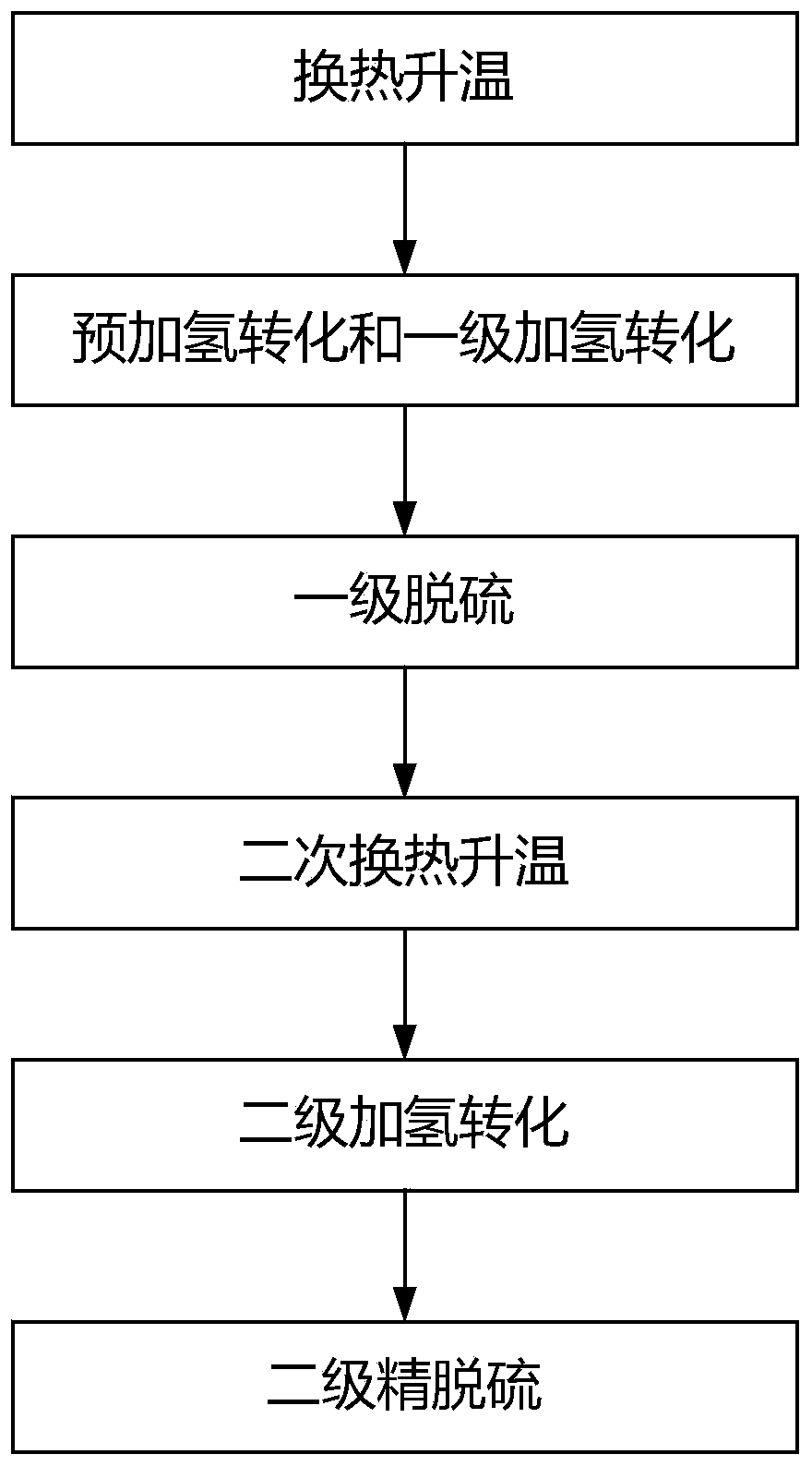

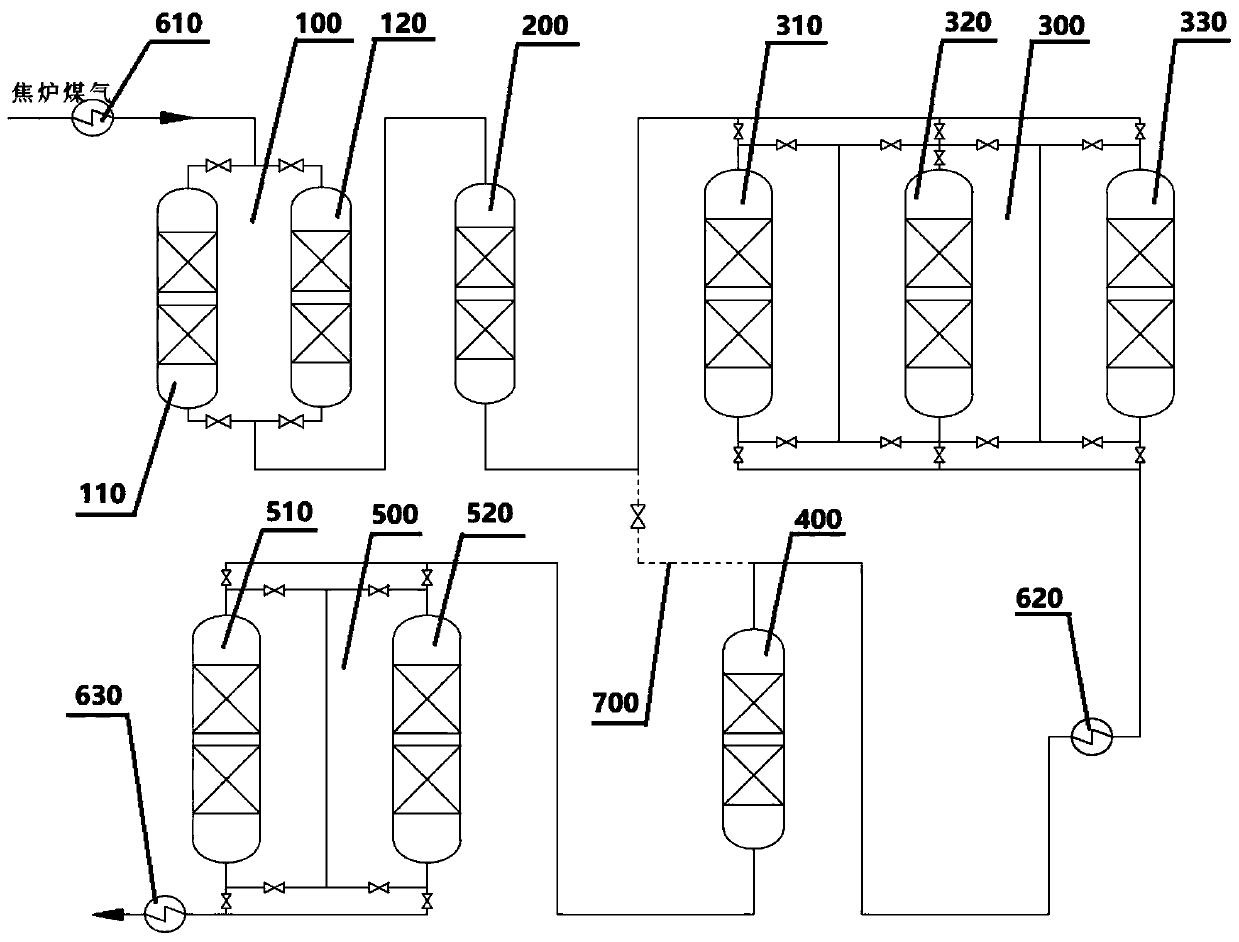

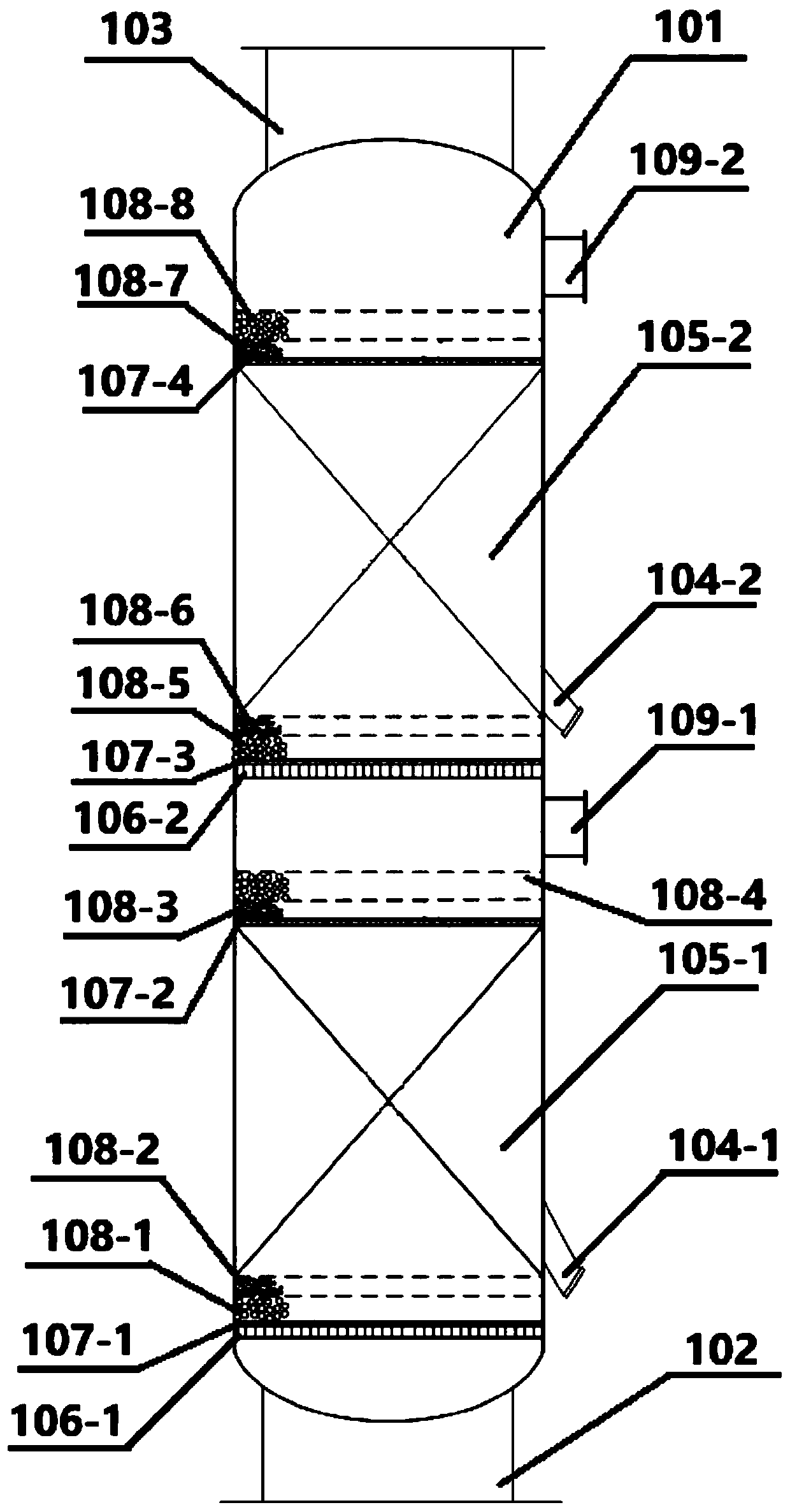

Method for deoxidizing and finely desulfurizing coke oven gas

ActiveCN108977233ARealize deep purificationImprove operational reliabilityDispersed particle separationGas contaminants removalUnsaturated hydrocarbonSulfur

The invention discloses a method for deoxidizing and finely desulfurizing a coke oven gas. The method comprises the following steps: (S1) heat exchanging and temperature rising; (S2) prehydrogenationconversion and first-stage hydrogenation conversion; (S3) first-stage desulfurization; (S4) secondary heat exchanging and temperature rising; (S5) second-stage hydrogenation conversion; (S6) second-stage fine desulfurization. According to the method for deoxidizing and finely desulfurizing the coke oven gas, disclosed by the invention, a two-stage coke oven gas hydrogenation deoxidization and finedesulfurization technology is adopted, most of organic sulfur in the coke oven gas can be converted into H2S by utilizing a first-stage hydrogenation deoxidization and desulfurization section, most of oxygen can be removed through hydrogenation, most of unsaturated hydrocarbon can be saturated through hydrogenation, and meanwhile, other impurities can be treated; the treated coke oven gas entersa second-stage hydrogenation deoxidization and fine desulfurization section, impurities of residual organic sulfur, unsaturated hydrocarbon, trace oxygen and the like can be subjected to secondary deep hydrogenation conversion and treatment, and deep purification of the coke oven gas can be realized.

Owner:太原智领科技有限公司

Pulverized coal co-combustion system of industrial boiler

ActiveCN102901089AHigh flame temperatureImprove burnout ratePulverulent fuel combustion burnersLump/pulverulent fuel preparationCombustion systemImpeller

The invention discloses a pulverized coal co-combustion system of an industrial boiler. With the system, layer combustion and suspension combustion can form in a furnace. The system includes a boiler, a raw coal supply device and a co-combustion device. The boiler comprises a furnace, a coal inlet located at the lower part of a front end wall, and a chain grate disposed at the lower part of a furnace inner chamber. The raw coal supply device is connected to the coal inlet through a coal hopper. The co-combustion device is arranged at the boiler tail, and is composed of a boiler-front mill, a pulverized coal combustor and a pulverized coal conveying pipe. The boiler-front mill includes a rotation shaft running through a primary milling chamber, an intermediate milling chamber and a fine milling chamber connected in order, a primary hammer type impeller, an intermediate hammer type impeller and a final hammer type impeller. The front end wall upper part of the primary milling chamber is provided with a coal inlet, and the chamber wall upper part of the fine milling chamber is provided with a pulverized coal nozzle. The pulverized coal combustor includes a combustor body and a combustion nozzle. The combustor body is equipped with a secondary air inlet and a pulverized coal inlet. And the pulverized coal conveying pipe connects the pulverized coal inlet of the combustor body and the pulverized coal nozzle of the boiler-front mill.

Owner:SHANGHAI INDAL BOILER RES INST

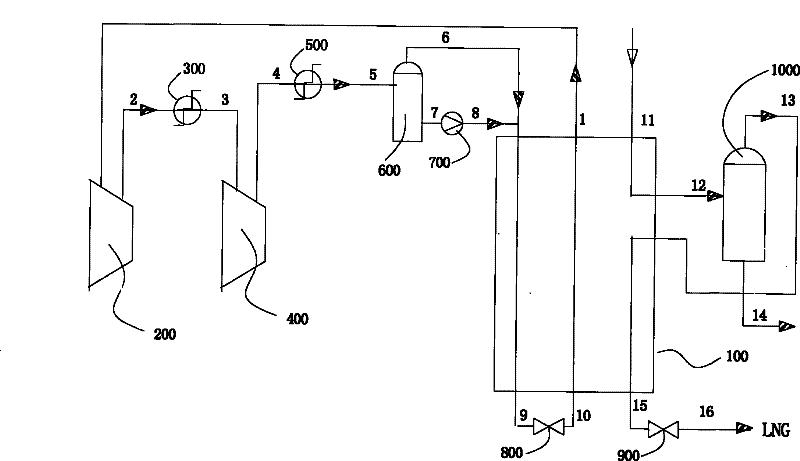

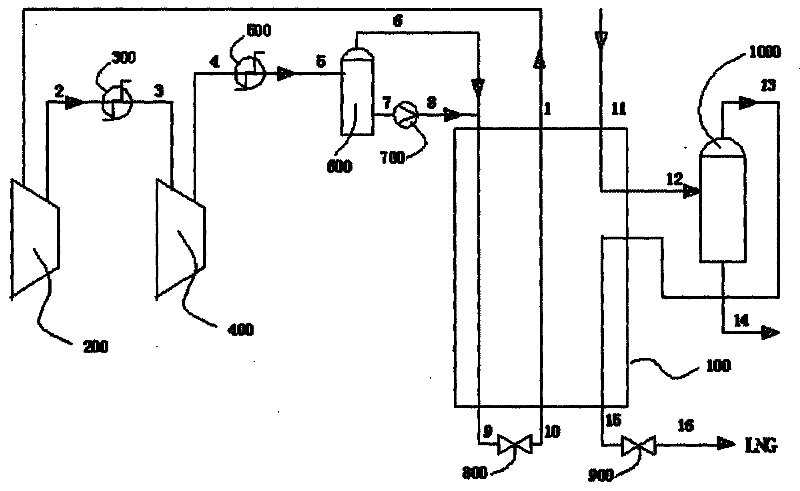

Gas liquefying process for mixed refrigerant and mixed refrigerant

The invention relates to a gas liquefying process for mixed refrigerant, which comprises the following steps: providing the mixed refrigerant which comprises the following components in percentage by mole: 5 to 10 percent of nitrogen, 30 to 40 percent of methane, 5 to 10 percent of ethylene, and 45 to 60 percent of propane; feeding the mixed refrigerant to a single refrigerant circulating system to carry out closed cycle to produce cold energy required by cooling gas; and exchanging heat of the gas needing to be liquefied and the refrigerant circulating system through a gas liquefying system so that the gas is cooled and liquefied. The process flow is simple, the components of the refrigerant are reasonable, and a liquefying device has the advantages of safe and reliable operation, simplework, flexible load adjustment and low energy consumption.

Owner:LIAONING CIMC HASHENLENG GAS LIQUEFACTION EQUIP CO LTD

Load locking and adjusting improved constant force spring support hanging bracket

The invention discloses a load locking and adjusting improved constant force spring support hanging bracket. The load locking and adjusting improved constant force spring support hanging bracket comprises a front end plate, a spring cover barrel, an outer frame, a rotation frame, a pull rod, a spindle, a tail end plate, a spring pull rod, a guiding sleeve and a load adjusting nut. One side face of the front end plate is fixed to the end face of one end of the spring cover barrel, and the outer frame is fixed to the other side face of the front end plate. The end portion of the rotation frame is located in the outer frame. The spindle penetrates the outer frame and the rotation frame to connect the outer frame with the rotation frame. The tail end plate is located in the other end of the spring cover barrel. A spring is arranged in the spring cover barrel, one end of the spring pull rod is connected with the guiding sleeve, and the other end of the spring pull rod penetrates the outer frame and then penetrates the front end plate, the spring and the tail end plate to be connected with the load adjusting nut. The guiding sleeve and the rotation frame are connected through a load bolt. The support hanging bracket is convenient to lock, the load adjusting range is wide, and load adjustment is convenient.

Owner:XIAN THERMAL POWER RES INST CO LTD

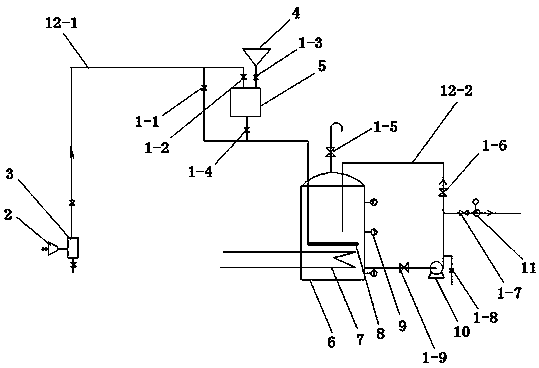

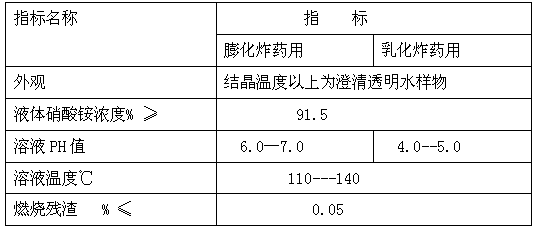

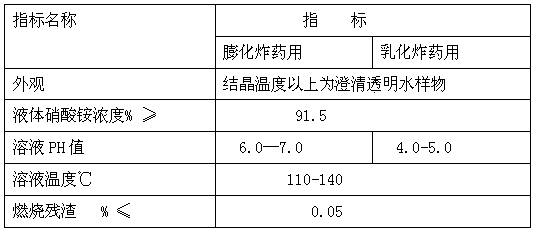

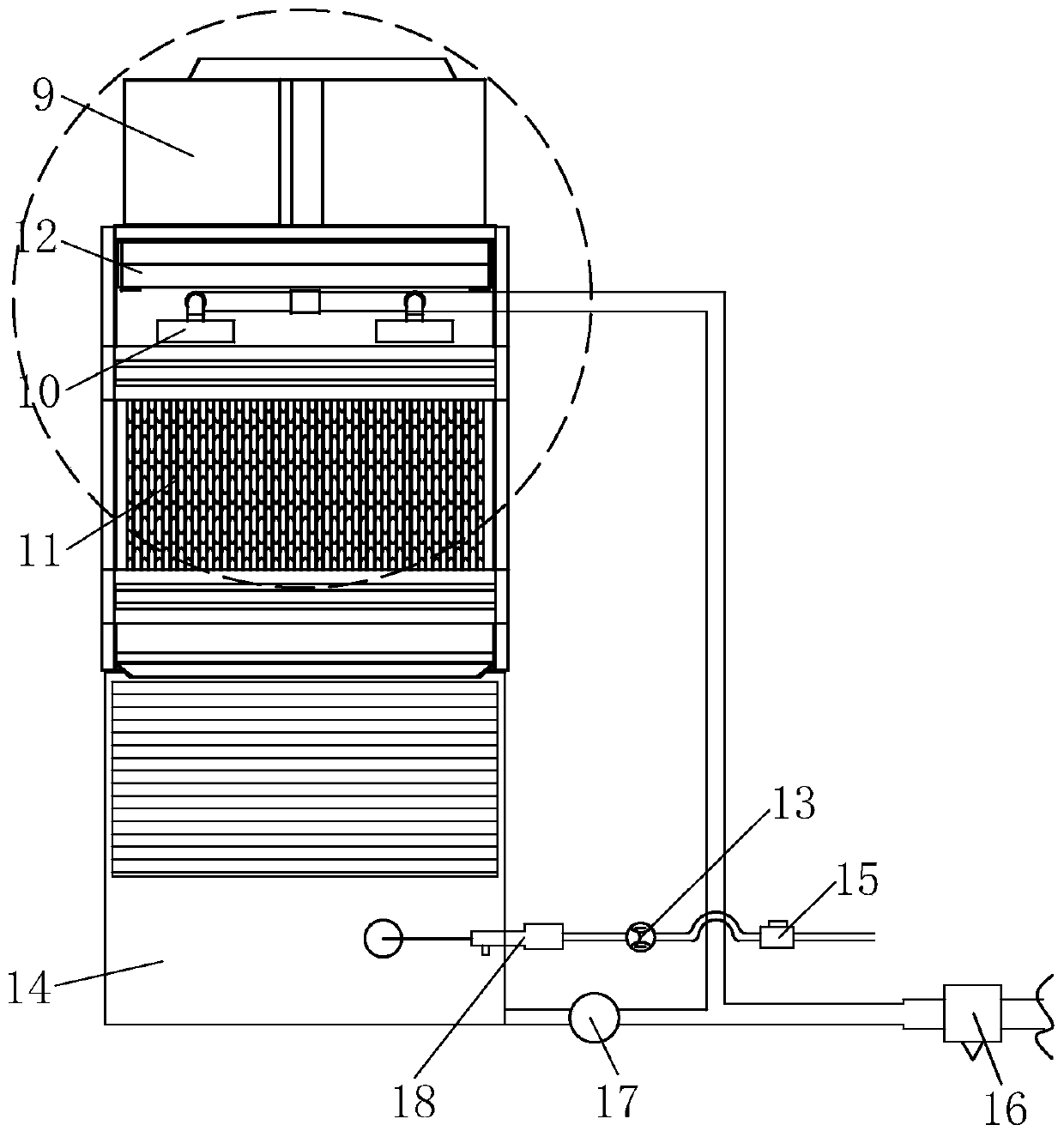

Quality control system of storage tank ammonium nitrate water solution

InactiveCN103482652APlay a buffer roleConsistent concentrationAmmonium nitratesCombustionControl system

The invention provides a quality control system of a storage tank ammonium nitrate water solution, which comprises a storage tank, wherein the upper part of the storage tank is provided with a filter; the filter is communicated with the top end of the storage tank through a pipeline; the inside of the storage tank is respectively provided with an air distributor and a heating tube; the air distributor is connected with an air compressor arranged outside the storage tank through a first pipeline; an outlet end positioned at the bottom end of the storage tank is connected with a circulating delivery pump; an outlet end of the circulating delivery pump is communicated with the upper end of the storage tank through a second pipeline; and the top end of the storage tank is connected with an acid-alkali tank for regulating the PH value. The control system can control the concentration, PH value, combustion residue and solution temperature index of the ammonium nitrate water solution, so that the ammonium nitrate water solution can comprehensively satisfy the standard requirements or demands of customers, and ensure the use safety.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

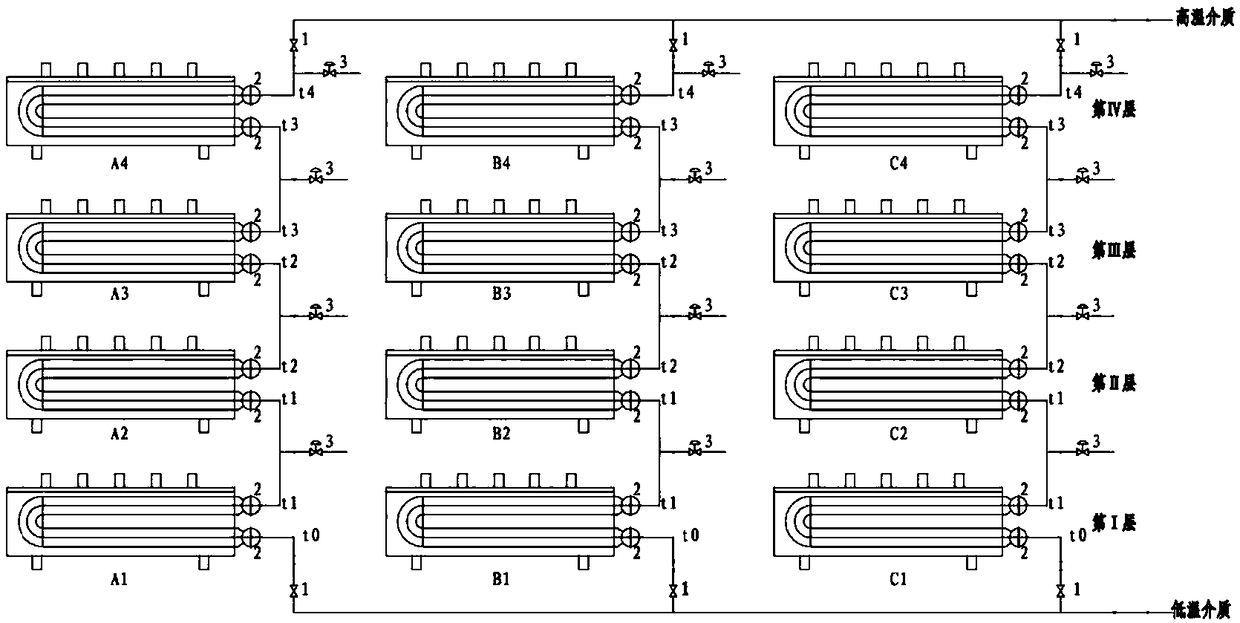

Solid particulate matter heat storage and release device, system and method

PendingCN109443064ALow construction costImprove the efficiency of the whole plantHeat storage plantsHeat exchange apparatusSlagCoal

The invention provides a solid particulate matter heat storage and release device. The device is characterized in that a heat exchange pipe is arranged inside a heat storage and exchange container, aheat storage medium is arranged in the heat storage and exchange container and is located outside the heat exchange pipe, a heat exchange medium is circulated inside the heat exchange pipe, the heat storage medium is solid particulate matter such as sand, coal ash or coal slag. The invention further provides a solid particulate matter heat storage and release system. The system is characterized inthat the solid particulate matter heat storage and release devices are designed in a modular mode, and are divided into multiply layers in the vertical direction according to the temperature gradient, the multiple groups of the solid particulate matter heat storage and release devices are arranged at each layer in the horizontal direction, the heat exchange pipes of the solid particulate matter heat storage and release devices of the adjacent layers of the same group are connected end to end through connecting pipes, the free end of the heat exchange pipe at the bottommost layer of each groupis connected with a low-temperature medium mater pipe, and the free end of the heat exchange pipe at the uppermost layer of each group is connected with a high-temperature medium master pipe. The invention further provides a solid particulate matter heat storage and release method. The method is characterized in that a bidirectional flow design is adopted, the heat exchange medium flows from topto bottom during heat storage, and the heat exchange medium flows from bottom to top during heat release. According to the device, the system and the method, the system is simple, the maintenance is convenient, the cost is low, and the application range is wide.

Owner:SHANGHAI BOILER WORKS

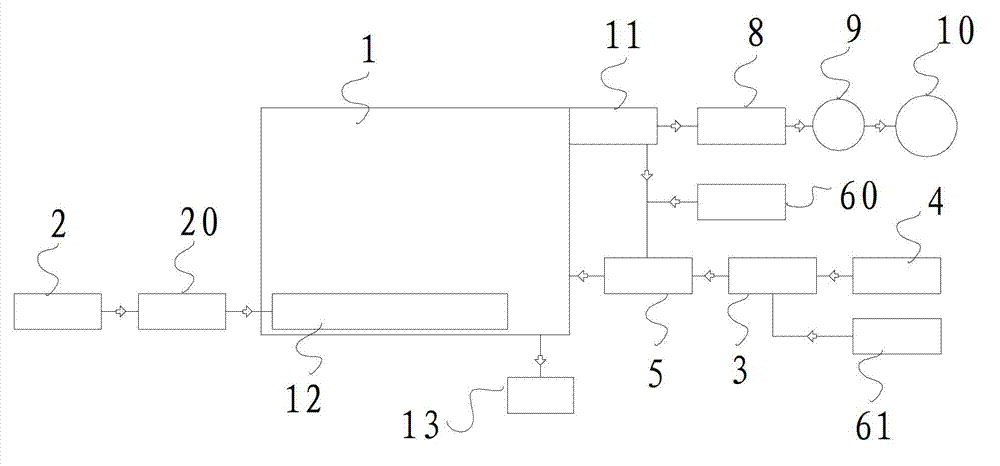

High-efficiency gasification device suitable for multiple kinds of coal

PendingCN104479751AEasy load adjustmentWide range of coal typesGasifier feeding meansGasification processes detailsSyngasSlag

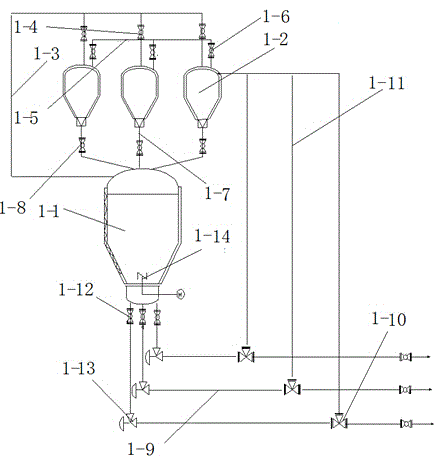

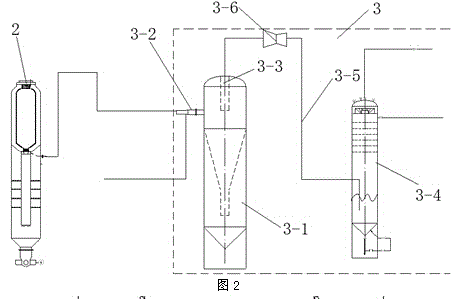

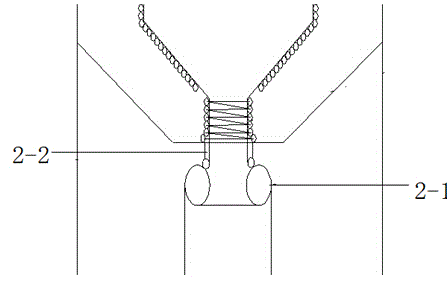

The invention discloses a high-efficiency gasification device suitable for multiple kinds of coal. The high-efficiency gasification device comprises pulverized coal conveying equipment, a gasification furnace and synthesis gas purification equipment, wherein the pulverized coal conveying equipment comprises a charging tank, two or three pulverized coal locking hoppers are arranged above the charging tank, each pulverized coal locking hopper is connected with the top of the charging tank through a discharging pipe, locking hopper equalizing pipes are connected among the three pulverized coal locking hoppers; a charging pipe is arranged at the bottom of the charging tank, the charging pipe is connected with a feeding opening of the gasification furnace; the gasification furnace is connected with the synthesis gas purification equipment. The high-efficiency gasification device is used for improving the existing pulverized coal conveying equipment, gasification furnace and synthesis gas purification equipment so as to have the advantages of convenience in regulating a load, wide coal application range, high gasification efficiency and carbon conversion rate, high synthesis gas washing efficiency, excellent treating capability of a slag-water system, and the like; a solution or available commercial selection is provided for solving the problem existing in the prior art.

Owner:YANKUANG GRP CO LTD

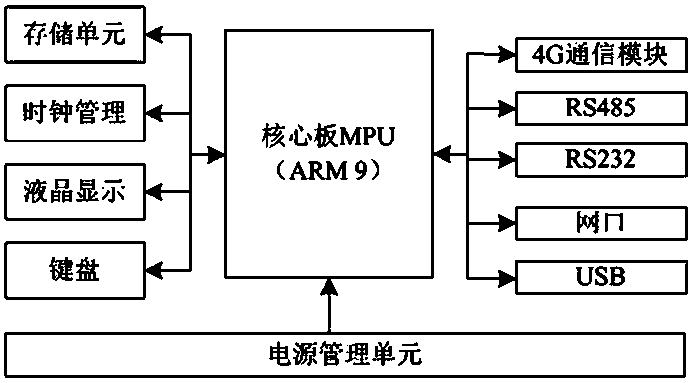

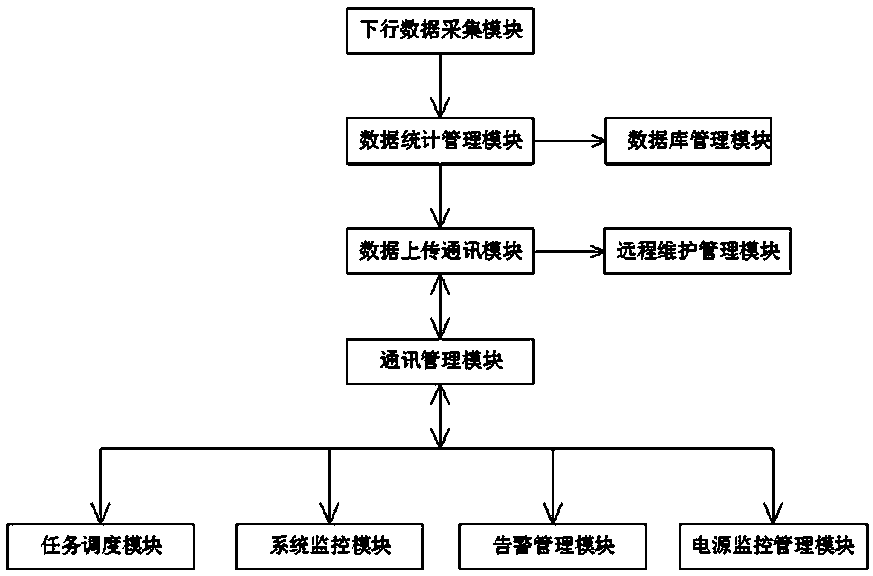

Distributed photovoltaic power station information acquisition and monitoring device

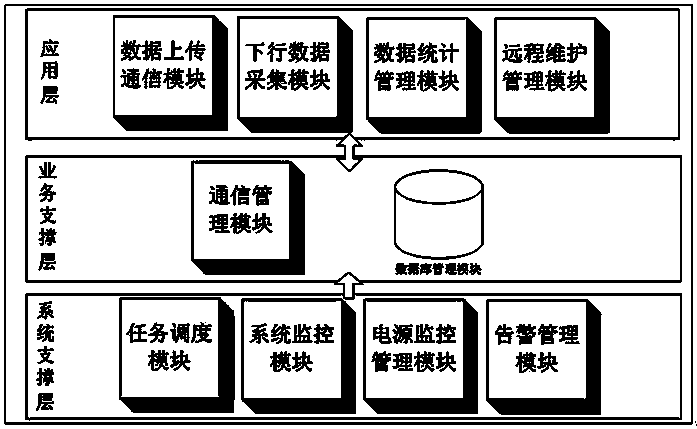

ActiveCN111130220AImprove integrityImprove accuracyElectric signal transmission systemsCircuit arrangementsData integritySoftware system

A distributed photovoltaic power station information acquisition and monitoring device relates to the technical field of photovoltaic power stations and is mainly composed of a hardware system and a software system. The hardware system is realized based on an industrial embedded core board of a 32-bit ARM9 microprocessor and consists of a core board, a power supply management unit, a clock management unit, a storage unit, a liquid crystal display unit and a peripheral interface unit group, the software system is divided into a system support layer, a service support layer and an application layer, information is acquired by a downlink data acquisition module and processed by a data statistics management module, and then information acquisition and monitoring are completed through data uploading and monitoring information transmission of a data uploading communication module. The device has a beneficial effect that a data timeliness inspection technology, a data integrity inspection technology and a data self-repairing technology which are suitable for distributed photovoltaic power station whole-station data monitoring are adopted so that timeliness, integrity and accuracy of the acquired data are ensured.

Owner:青海绿能数据有限公司

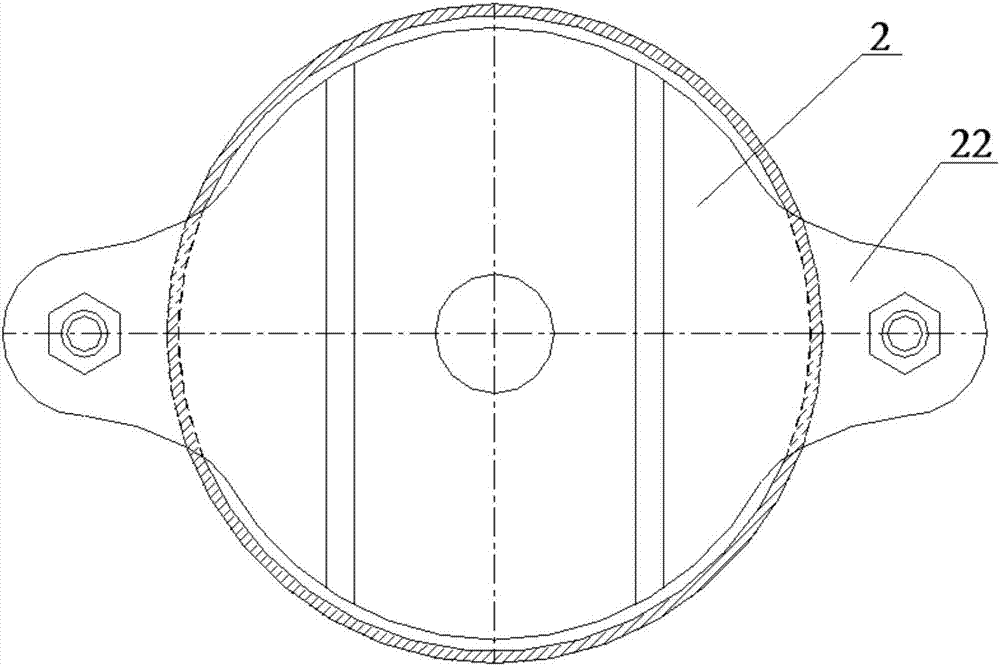

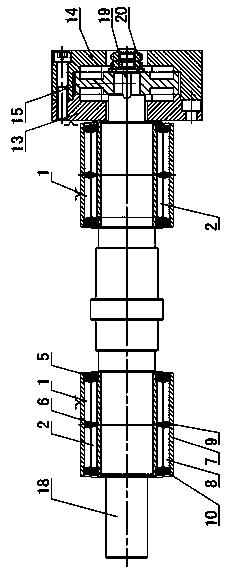

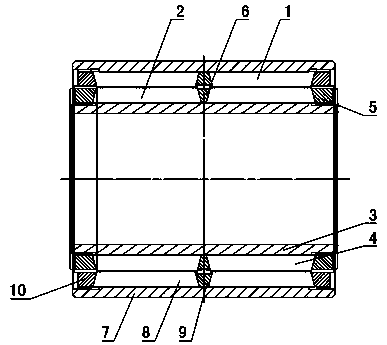

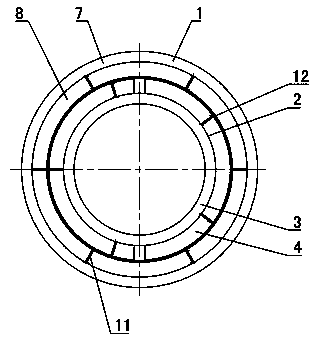

Permanent magnet type magnetic bearing pair

The invention belongs to the technical field of bearings and discloses a permanent magnet type magnetic bearing pair. The permanent magnet type magnetic bearing pair is characterized in that an innerring (3) of a radial bearing sleeves a shaft (18), outer ring magnetic steel (8) is coaxially mounted on the inner wall of an outer ring (7), inner ring magnetic steel (4) is coaxially mounted on theouter wall of the inner ring (3), and the outer wall of the inner ring magnetic steel (4) and the inner wall of the outer ring magnetic steel (8) are identical in magnetic polarity. One side, close toa thrust collar (22) of a thrust disc (15) of an axial bearing is provided with annular rotating magnetic steel (17). One side, close to the thrust disc (15), of the thrust collar (22) is provided with annular fixed magnetic steel (16). Adjacent sides of the rotating magnetic steel (17) and the fixed magnetic steel (16) are identical in magnetic polarity. The permanent magnet type magnetic bearing pair is free of noise and heat generation, lubrication in a utilization process is avoided, long service life is realized, and bearing of both radial force generated by a radial load and axial forcegenerated by an axial load can be realized.

Owner:SHANDONG FENGGANG MACHINERY EQUIP

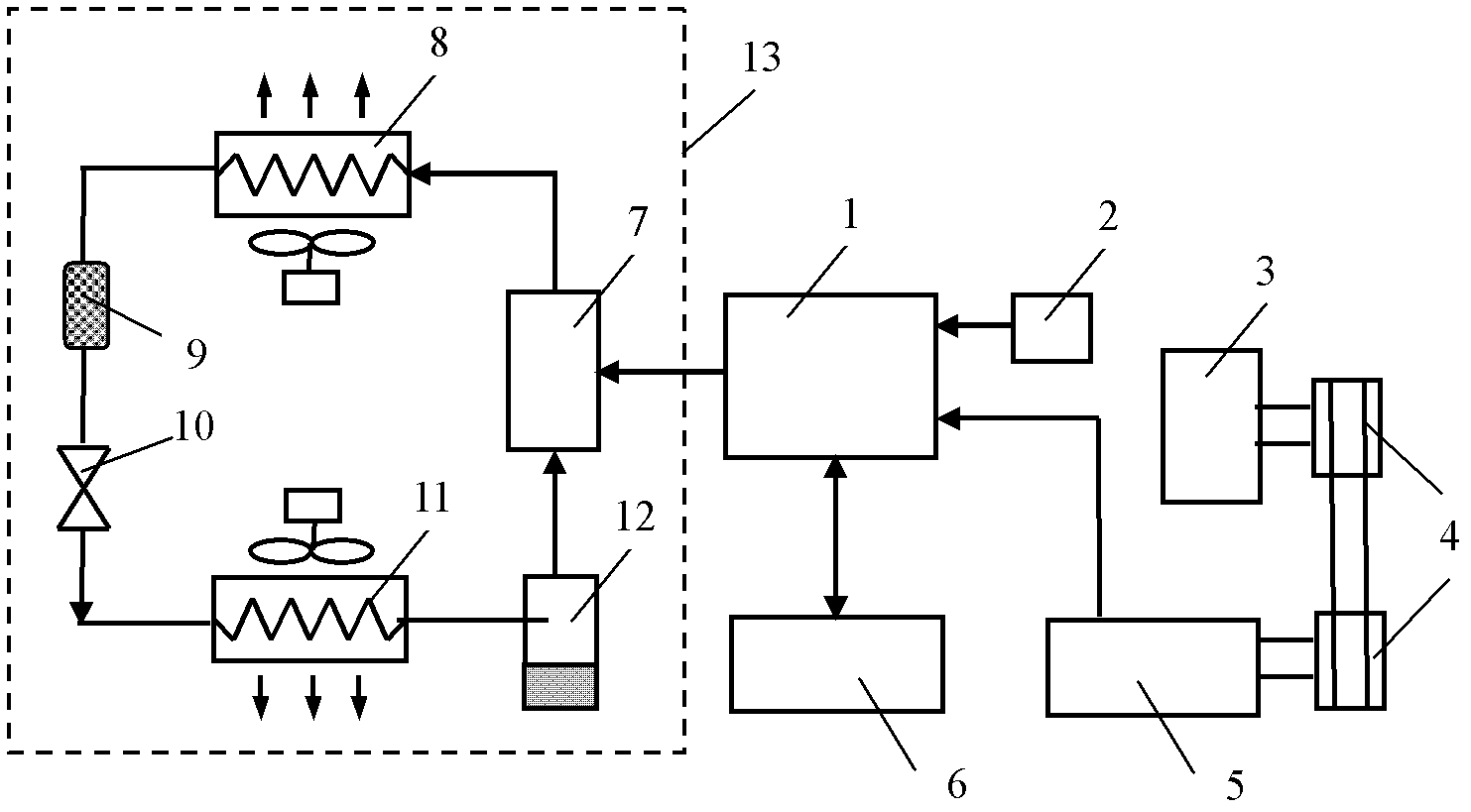

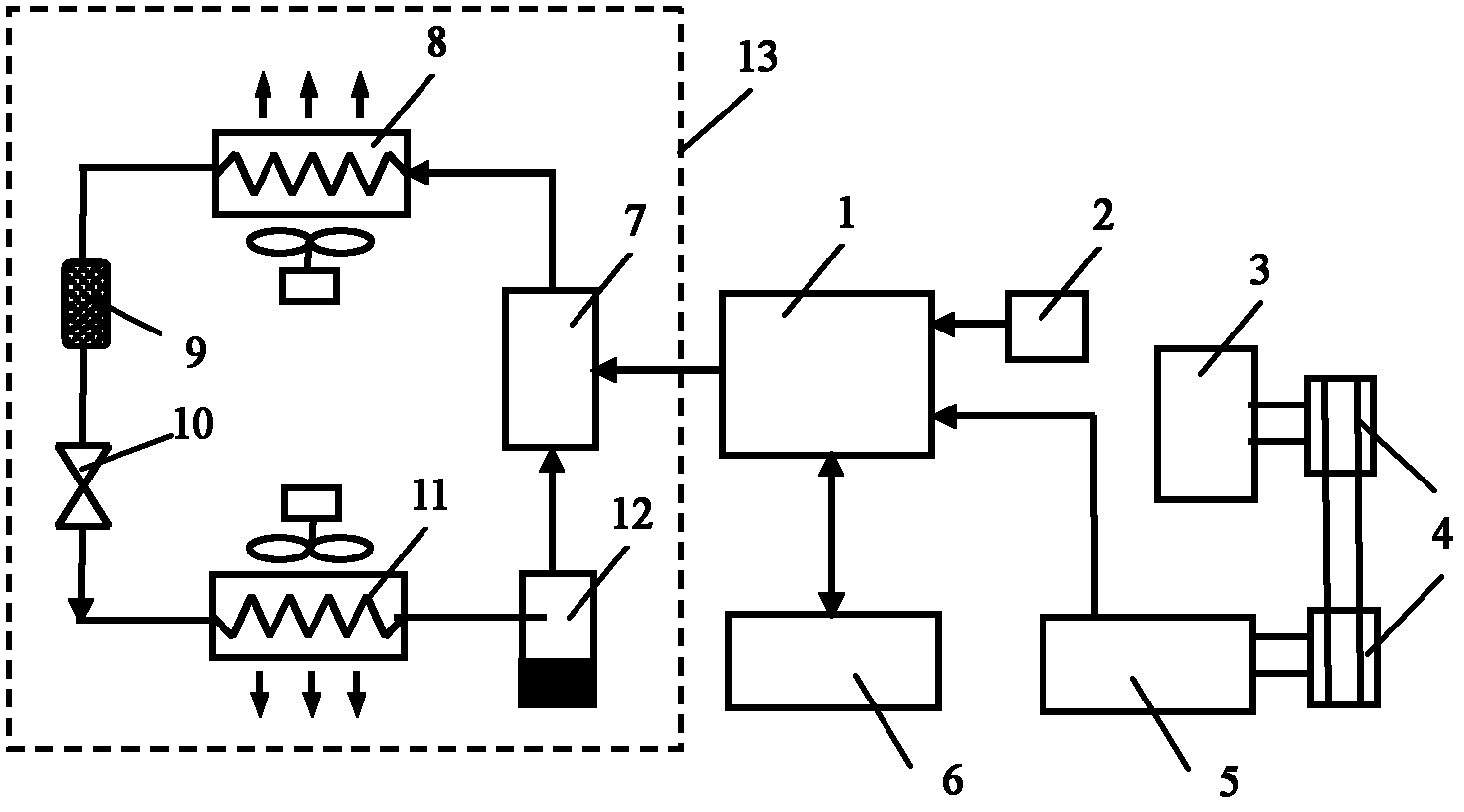

Electric refrigerating unit for refrigerated vehicle

InactiveCN102310746ARealize energy-saving operationEasy load adjustmentAir-treating devicesVehicle heating/cooling devicesElectric generatorFuel oil

The invention discloses an electric refrigerating unit for a refrigerated vehicle. The electric refrigerating unit is characterized in that a full-closed variable frequency refrigerating compressor is arranged in a refrigerating circulating system, and the full-closed variable frequency refrigerating compressor is driven by output electrical energy of a variable frequency controller; the input end of the variable frequency controller has three selective power supply modes, respectively a vehicle engine drives a generator through a mechanical transmission mechanism to supply power, a storage battery supplies power directly, and a power supply interface is connected with the mains or other external power supply to supply power; and the variable frequency controller is used for converting the electrical energy input by the three selective power supply modes, and the conversion is used for regulating the frequency and voltage of an output alternating current according to the thermal load of the refrigerated vehicle to drive the full-closed variable frequency refrigerating compressor to run at variable revolving speeds, so that the refrigerating capacity of the refrigerating unit is matched with the thermal load of the refrigerated vehicle. The refrigerating unit has the functions of independent and direct-coupled refrigerating units for road transportation, is not provided with a fuel oil engine and a motor which are necessary for the independent refrigerating unit, and has the advantages of wide temperature regulating range, compact structure, miniaturization, energy conservation and environmental friendliness.

Owner:HEFEI UNIV OF TECH

Pulverized coal co-combustion system of industrial boiler

ActiveCN102901089BHigh flame temperatureImprove burnout ratePulverulent fuel combustion burnersLump/pulverulent fuel preparationCombustion systemImpeller

The invention discloses a pulverized coal co-combustion system of an industrial boiler. With the system, layer combustion and suspension combustion can form in a furnace. The system includes a boiler, a raw coal supply device and a co-combustion device. The boiler comprises a furnace, a coal inlet located at the lower part of a front end wall, and a chain grate disposed at the lower part of a furnace inner chamber. The raw coal supply device is connected to the coal inlet through a coal hopper. The co-combustion device is arranged at the boiler tail, and is composed of a boiler-front mill, a pulverized coal combustor and a pulverized coal conveying pipe. The boiler-front mill includes a rotation shaft running through a primary milling chamber, an intermediate milling chamber and a fine milling chamber connected in order, a primary hammer type impeller, an intermediate hammer type impeller and a final hammer type impeller. The front end wall upper part of the primary milling chamber is provided with a coal inlet, and the chamber wall upper part of the fine milling chamber is provided with a pulverized coal nozzle. The pulverized coal combustor includes a combustor body and a combustion nozzle. The combustor body is equipped with a secondary air inlet and a pulverized coal inlet. And the pulverized coal conveying pipe connects the pulverized coal inlet of the combustor body and the pulverized coal nozzle of the boiler-front mill.

Owner:SHANGHAI INDAL BOILER RES INST

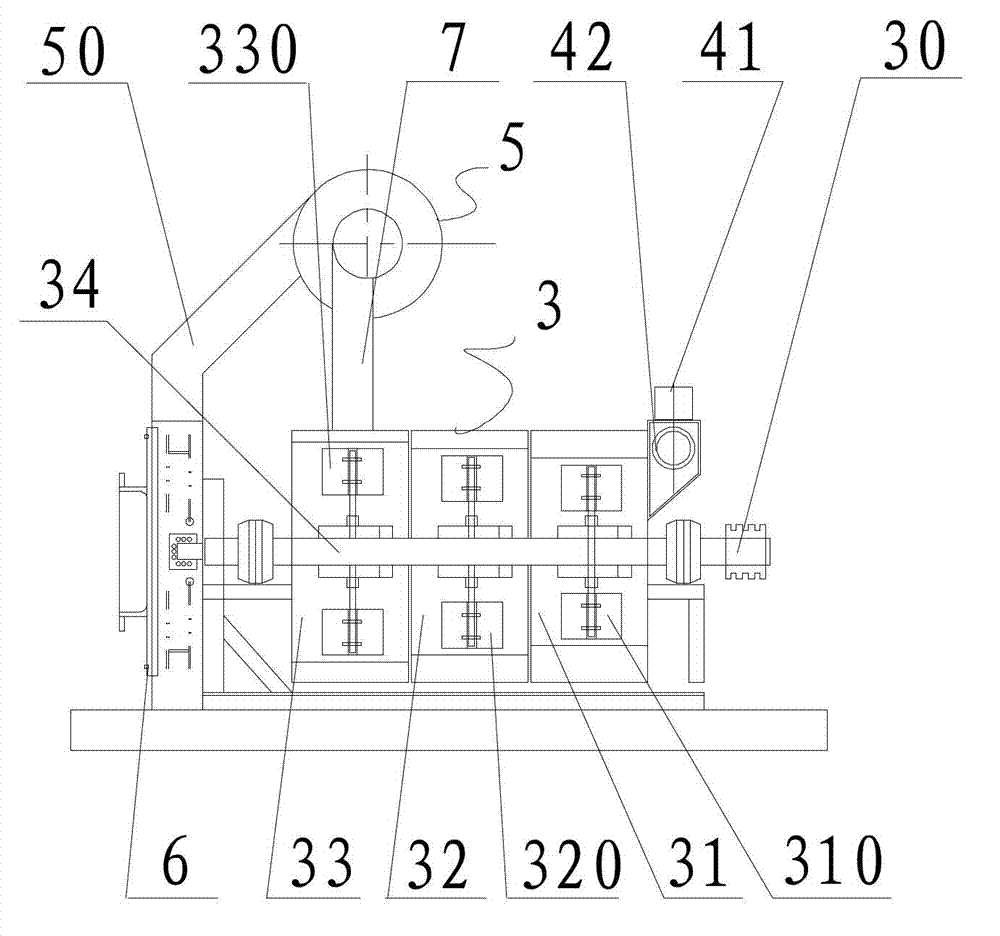

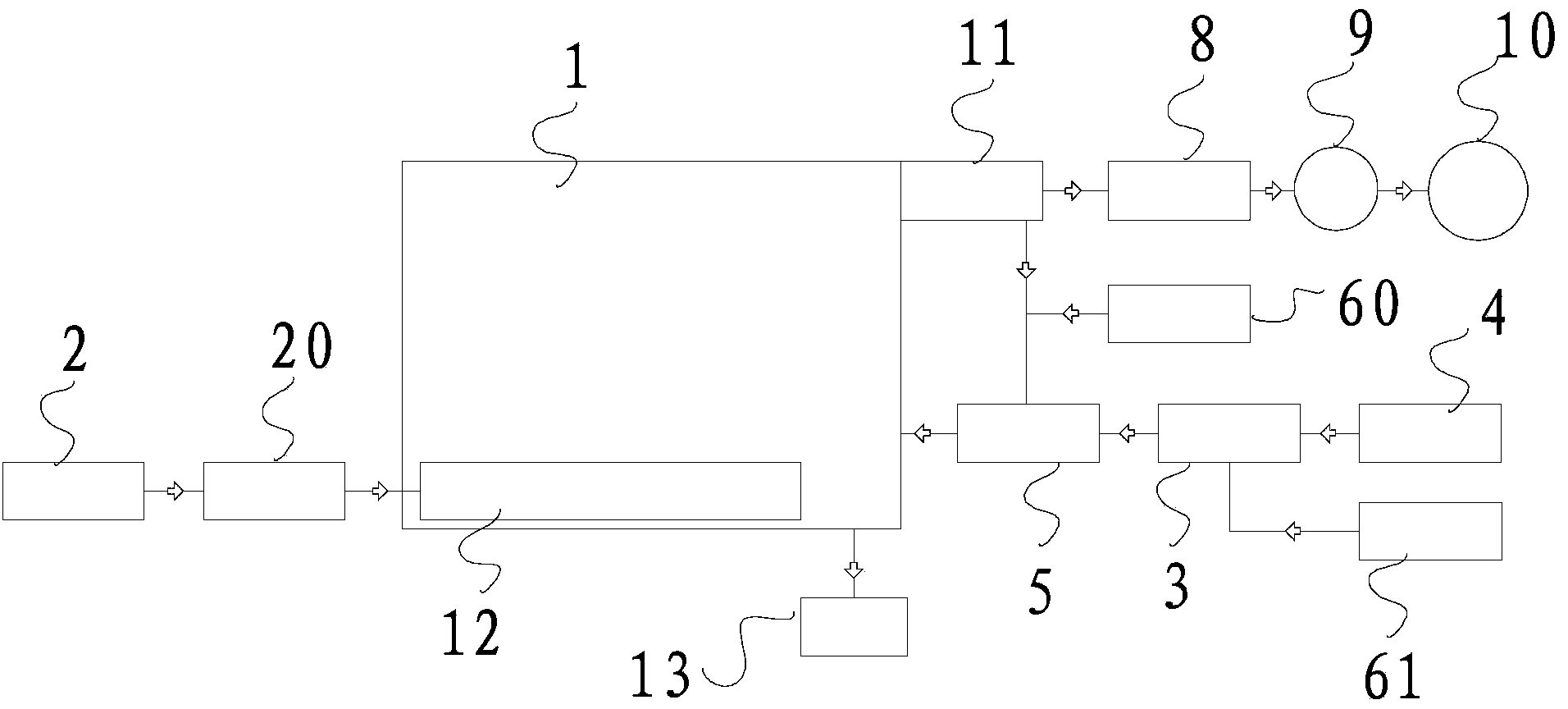

A hydraulically loaded machine-fluid mixed flow test platform and its application

ActiveCN109855883BOptimal allocation ratioShorten the development cycleVehicle testingMachine part testingMachineTest bench

The invention relates to a hydraulically loaded machine-liquid mixed flow test platform and application thereof. The test platform is capable of realizing performance testing of a hydraulic transmission unit in a hydraulic mechanical buncher and efficiency detection of a variable speed device. On the basis of simulation of the actual working conditions and working conditions, the test platform iscapable of testing and analyzing the structure and performances and service lives of parts of the hydraulic mechanical buncher product, thereby realizing the optimal allocation proportion of the mechanical flow to the hydraulic flow in the composite transmission. Meanwhile, the reliable scientific basis is provided for evaluating the product design and quality; the product development cycle is reduced; and the product quality is improved. According to the invention, the test platform employs a hydraulic loading system; the manufacturing cost is low; and the maintenance becomes convenient. Thetest efficiency is high in testing; the load adjustment becomes convenient and stable. With the closed-loop speed control of the rotating speed, the stability of rotating speed testing is high. The test platform has a reasonable structural design and has advantages of simpleness, high reliability, safe operation and saved cost.

Owner:SHANDONG UNIV OF SCI & TECH

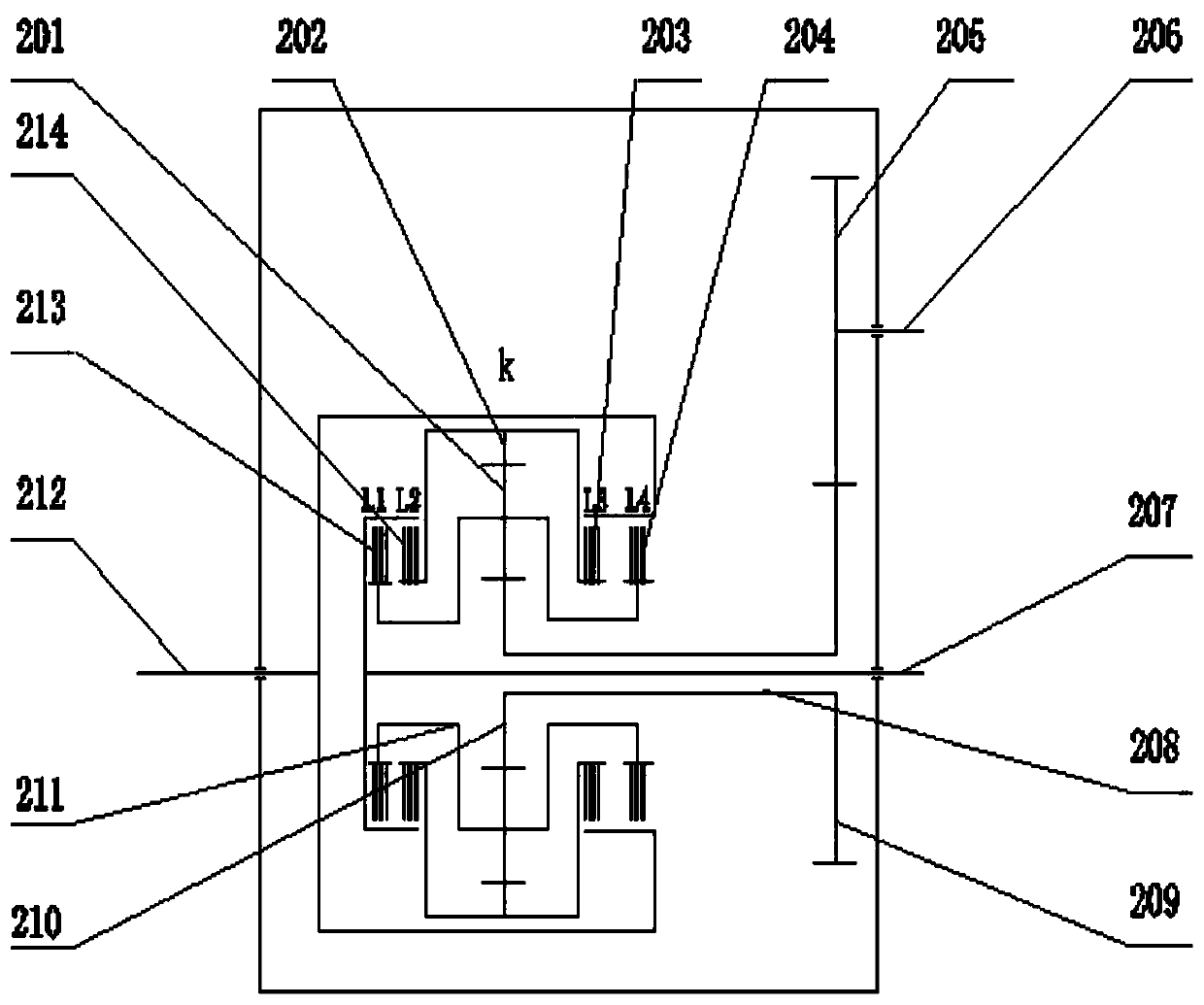

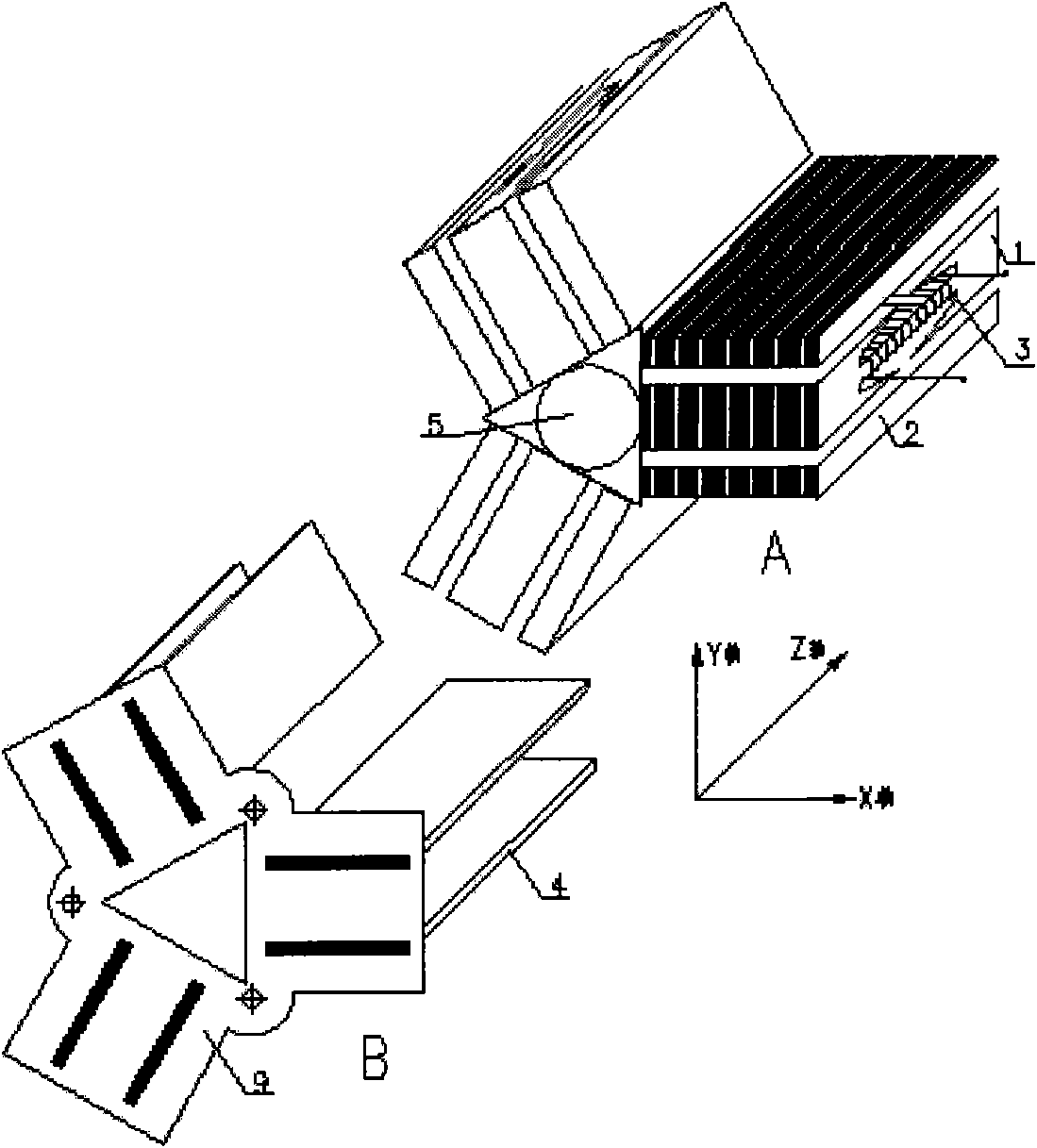

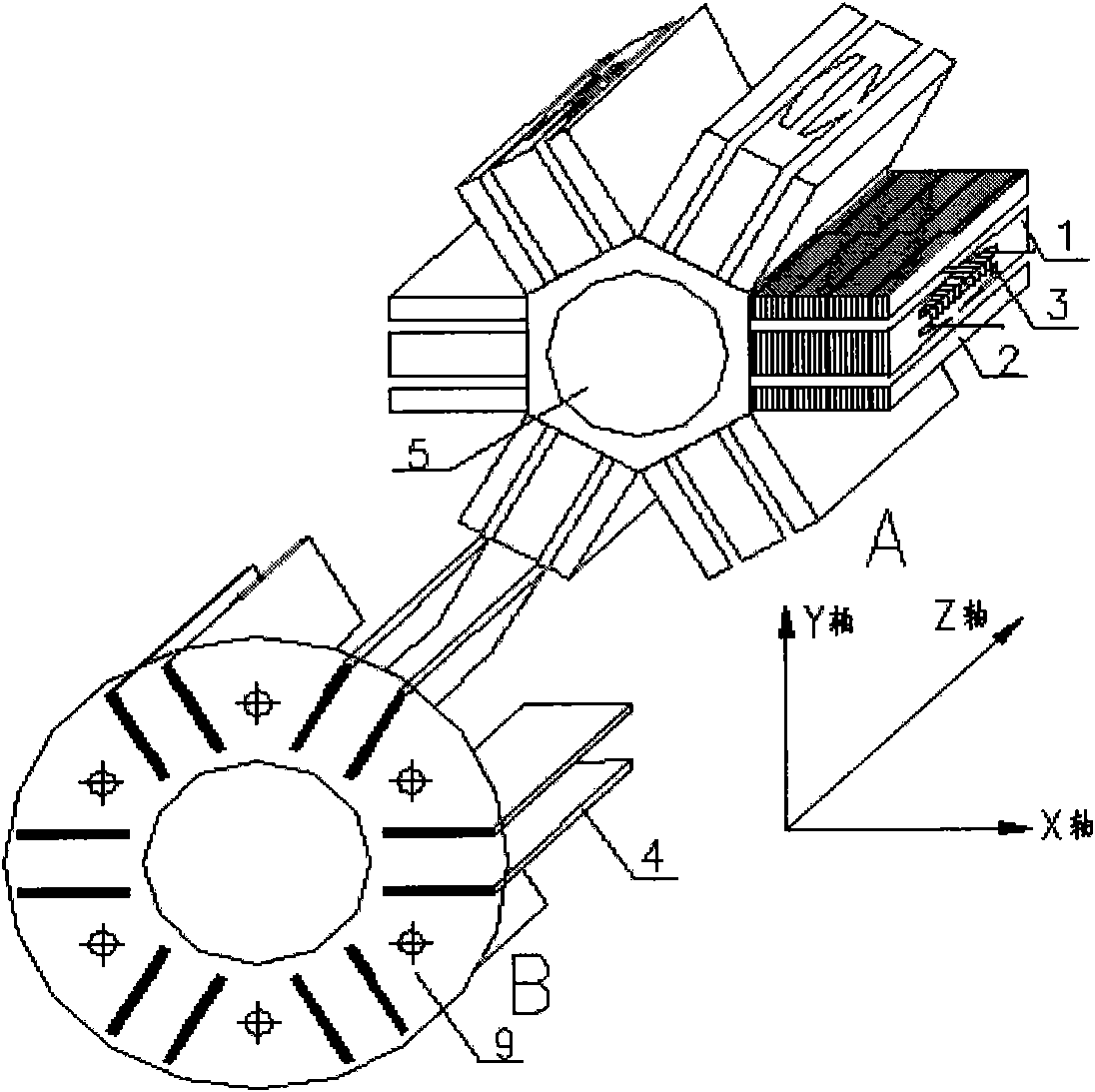

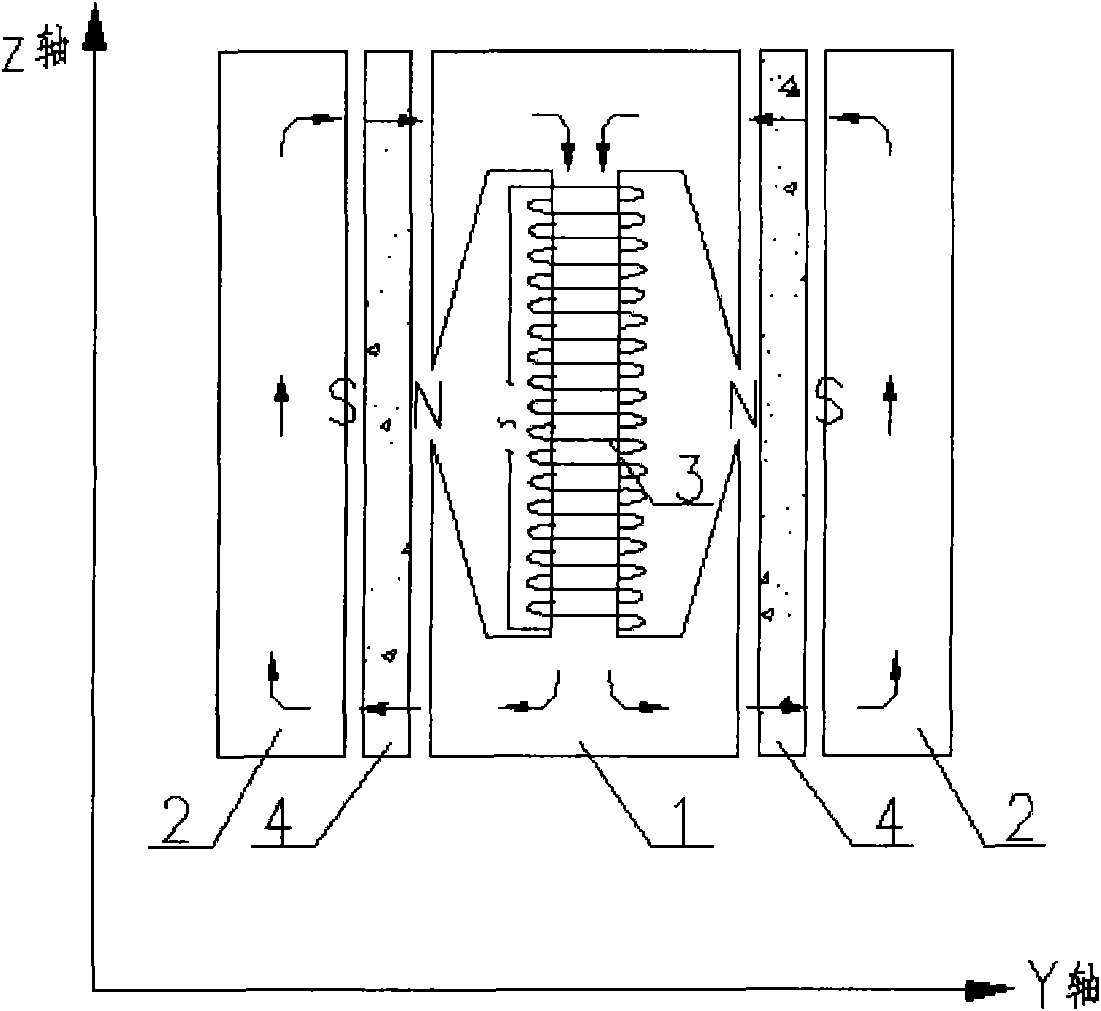

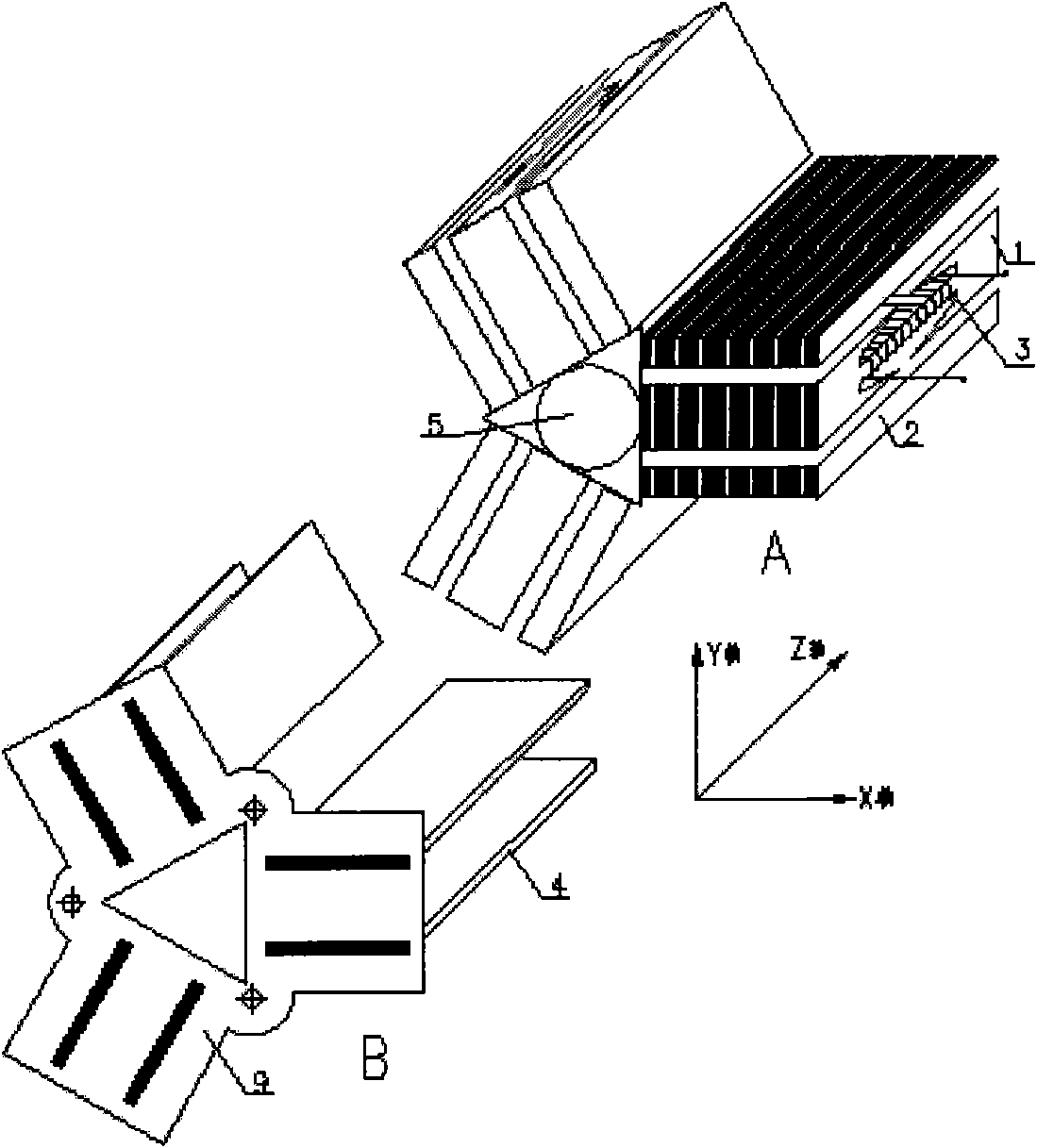

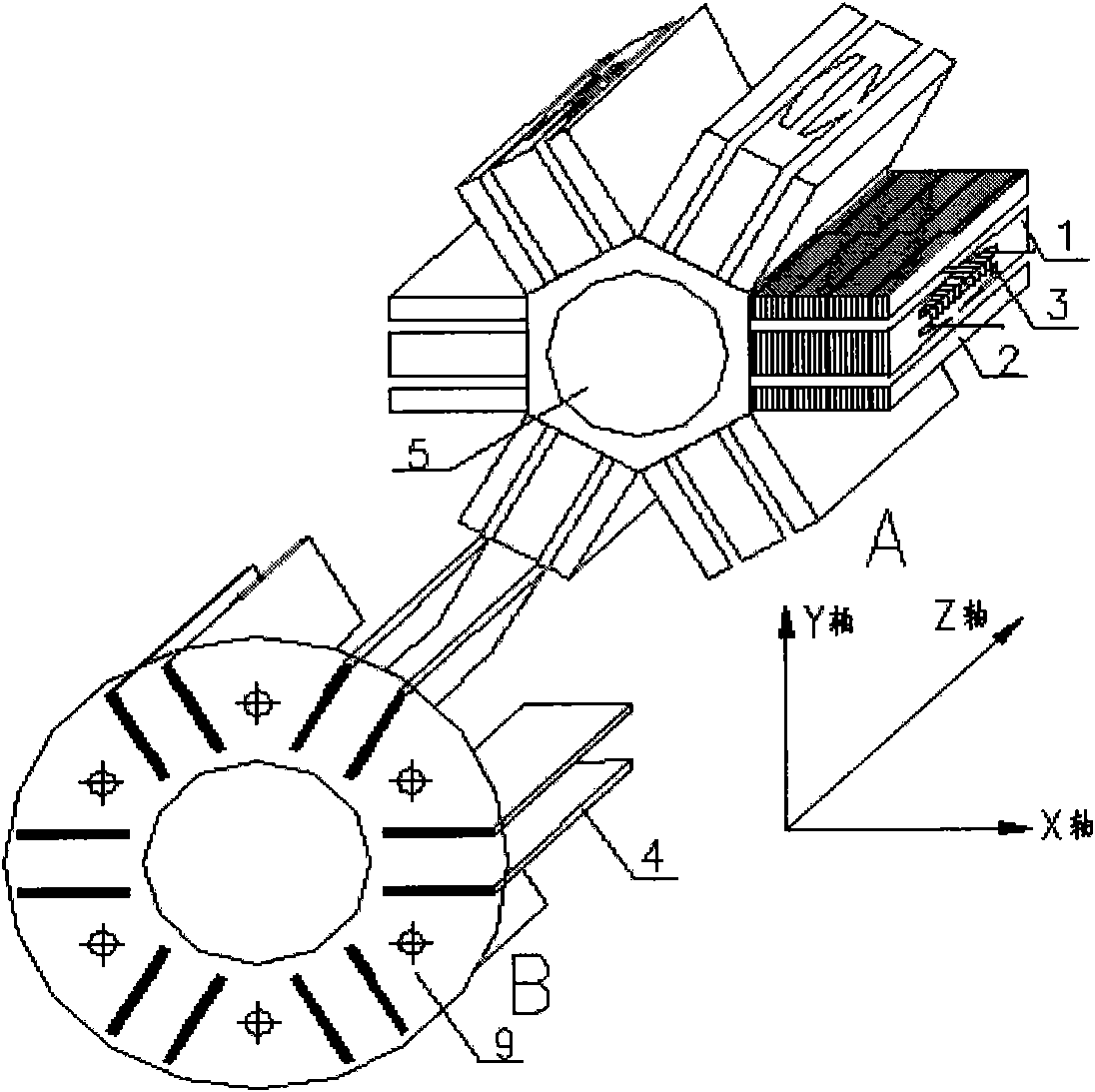

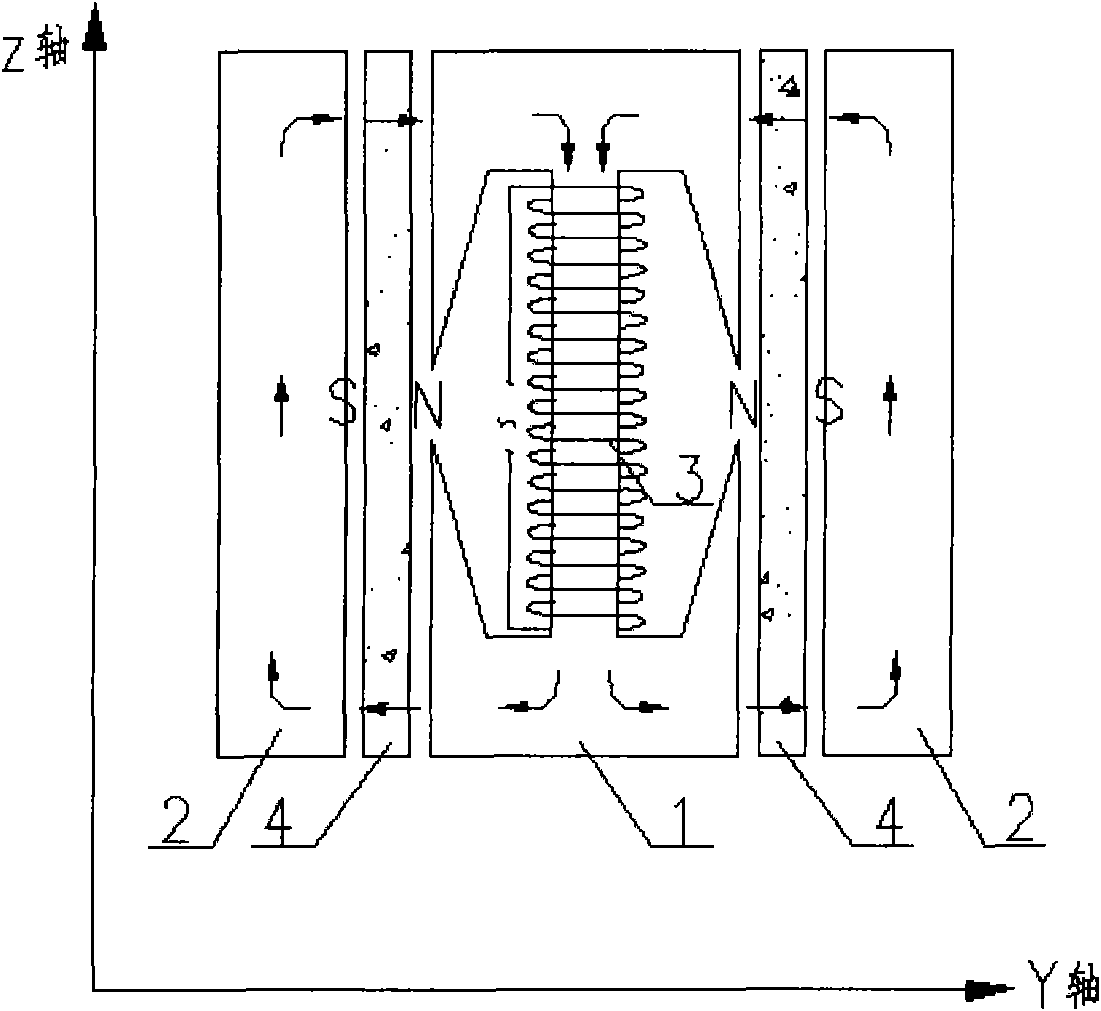

Multipath magnetic circuit unit lamellar permanent-magnet linear oscillating motor

InactiveCN101789661AThe production process is simpleFlexible structureMagnetic circuit rotating partsSynchronous machinesPhysicsStator

The invention relates to a multipath magnetic circuit unit lamellar permanent-magnet linear oscillating motor comprising a stator part and a rotor part; the stator part comprises a tubular cavity and magnetic circuit units; the tubular cavity has outer surfaces in a regular polyhedron; the magnetic circuit units are arranged on the outer surfaces; each magnetic circuit unit comprises a middle magnetic conductor and two magnetic conductors, wherein the longitudinal section of the middle magnetic conductor is in an H shape, a column of the middle magnetic conductor is wound by a coil, the two magnetic conductors are arranged at both sides of the middle magnetic conductor, and a strip-shaped air gap is arranged between the middle magnetic conductor and each of the magnetic conductors; the rotor part comprises a plurality of lamellar permanent magnets and symmetrical type magnetic circuits, wherein the plurality of lamellar permanent magnets are vertically arranged on connecting pieces in a radial shape, are inserted into a rectangular hole positioned in the connecting piece positioned at one end of the tubular cavity and extend into a rectangular hole positioned in the connecting piece positioned at the other end of the tubular cavity; each magnetic circuit unit is positioned among the lamellar permanent magnets; the symmetrical type magnetic circuits are formed by symmetrically magnetizing the middle magnetic conductor and the magnetic conductors along the length direction of the middle magnetic conductor; the coil generates a magnetic field by being electrified with alternating current and forms a magnetic field with alternate positive and negative directions in the strip-shaped air gaps through the symmetrical type magnetic circuits; and the rotor does reciprocating oscillation motion along the length directions of the strip-shaped air gaps in the strip-shaped air gaps under the action of the magnetic field.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

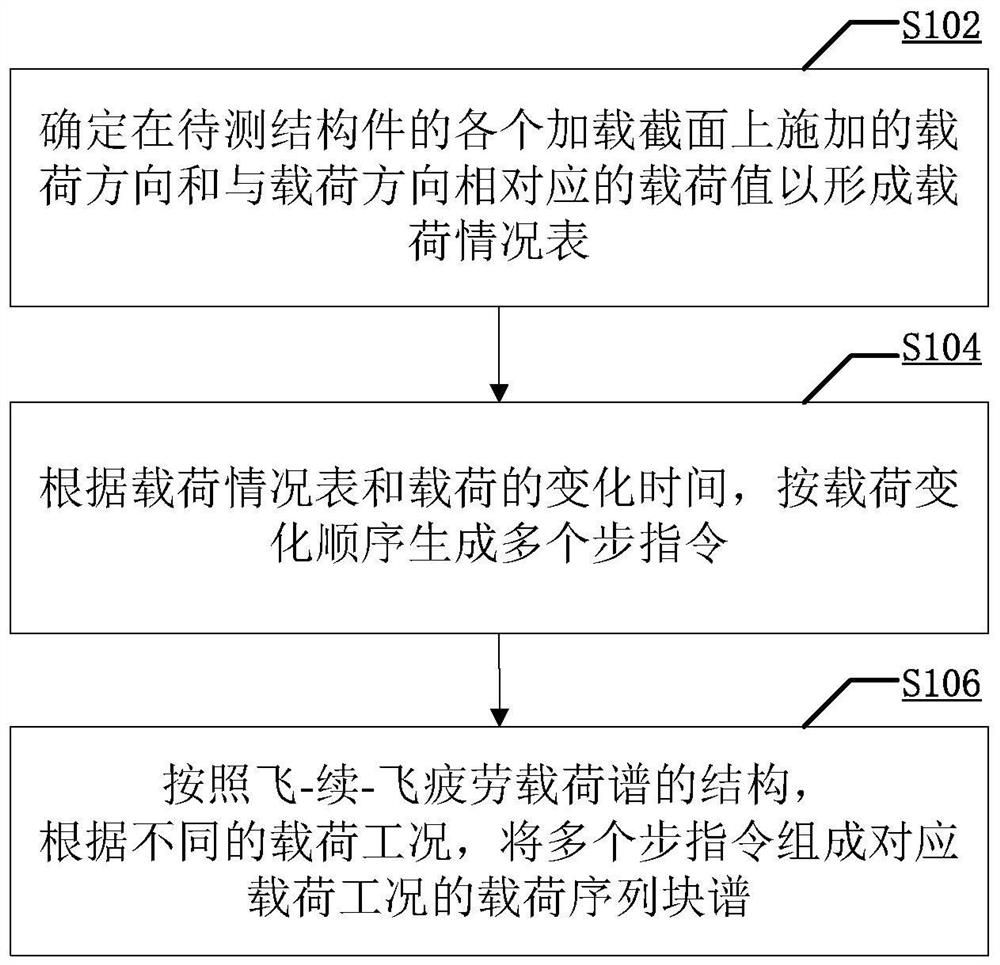

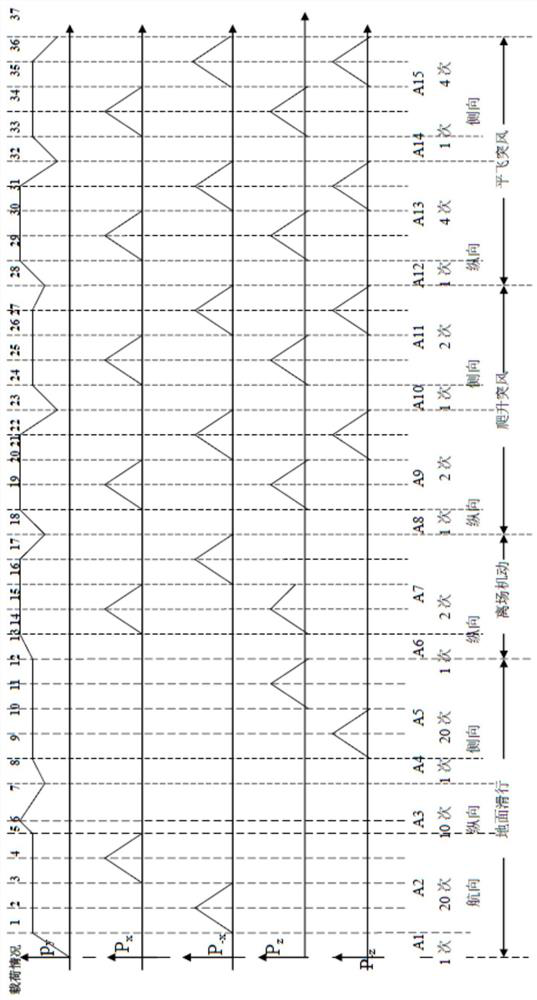

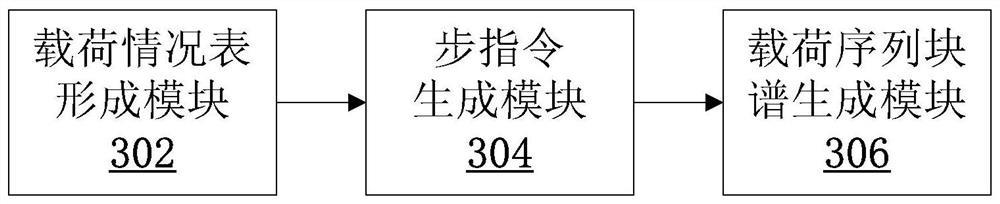

Fatigue test loading spectrum forming method and device and fatigue performance testing method

PendingCN112763304AGuaranteed test accuracyGuaranteed validityStrength propertiesFatigue loadingStructural fatigue

The invention relates to a fatigue test loading spectrum forming method and device and a fatigue performance testing method, belongs to the technical field of aircraft environment engineering, and aims to solve the problems that an existing load loading control system cannot directly recognize a structural fatigue load spectrum and cannot apply a load. The fatigue test loading spectrum forming method comprises the following steps of: determining the direction of load applied to each loading section of a to-be-tested structural member and a load value corresponding to the load direction to form a load condition table; according to the load condition table and the change time of the load, generating a plurality of step instructions according to a load change sequence; and according to the structure of a flight-continuation-flight fatigue load spectrum and different load working conditions, enabling the multiple step instructions to form load sequence block spectra corresponding to the load working conditions. With the fatigue test loading spectrum forming method and device and the fatigue performance testing method of the invention adopted, a structure fatigue load spectrum can be converted into a fatigue test loading spectrum identified by a loading control system, and the test efficiency is improved on the basis of ensuring the test accuracy and effectiveness.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

Improved method for increasing cold box inlet carbon dioxide analysis speed

InactiveCN112504772AFast analysisShorten sampling analysis timeWithdrawing sample devicesAnalysing gaseous mixturesProcess engineeringEnvironmental engineering

The invention belongs to the technical field of steel production, and particularly relates to an improved method for increasing the cold box inlet carbon dioxide analysis speed. The method comprises the following steps: adding a sampling valve and a sampling pipeline at the inlet of a cold box, connecting the original sampling pipeline and the sampling pipeline at the inlet of the cold box in parallel to carbon dioxide online analysis, adding an electromagnetic valve on the parallel pipeline, switching the electromagnetic valve at any time, finally, additionally arranging a selector switch, used for controlling the electromagnetic valve, on a central control DCS, and enabling the electromagnetic valve to act to achieve online monitoring of carbon dioxide at the inlet of the cold box. The carbon dioxide sampling analysis time at the inlet of the cold box is shortened, the central control DCS can monitor data at any time, and load adjustment during production fluctuation is facilitated.

Owner:HEILONGJIANG JIANLONG CHEM

Method for synthesizing ethylene glycol from coke oven gas and converter and/or blast furnace gas to co-produce lng

ActiveCN109111341BFull and efficient useReduce wasteOrganic compound preparationGaseous fuelsChemical industryProcess engineering

The invention relates to a method for synthesizing ethylene glycol and co-producing LNG by using coke oven gas, converter gas and blast furnace gas, which belongs to the field of chemical technology. Compression treatment, and then rough desulfurization; remove impurities from coke oven gas after desulfurization treatment; compress, finely desulfurize and remove O 2 ; Then the gas passes through the amine method to CO 2 The gas is removed; finally, the product LNG is separated by cryogenic cooling, and H is separated at the same time. 2 and rich CO, then for H 2 Purify; secondly, dedust and detar the converter and blast furnace gas; perform compression and impurity removal, and desulfurize and remove O 2 , then CO on the gas 2 Removal treatment; combine the purified gas with the CO-enriched gas to purify the CO gas, and finally synthesize the purified CO through an esterification-carbonylation cycle to produce DMO, and DMO and purified hydrogen to produce ethylene glycol; the first application of the present invention in the synthesis of ethylene glycol technology.

Owner:戴乐亭 +3

A method and device for controlling the pH value of a finished ammonium nitrate aqueous solution

The invention provides a method for controlling the pH value of the finished ammonium nitrate aqueous solution, which includes adjusting the temperature and pressure of the ammonium nitrate aqueous solution in a storage tank; stirring with compressed air; circulating pumps for self-circulation mixing; calculating and adding acid or lye according to the pH value Adjust the pH to it. The present invention also provides a control device, including a storage tank, an air distributor is horizontally arranged in the middle of the storage tank, and the air distributor is connected with an air compressor arranged outside the storage tank through a first pipeline, and the first The pipeline is connected with an acid-base tank for adjusting the pH value; the outlet end at the bottom of the storage tank is connected with a circulation delivery pump, and the outlet end of the circulation delivery pump communicates with the upper end of the storage tank through a second pipeline, and the second pipeline The outlet end of the tank is located in the middle and upper part of the storage tank. The invention accurately and quickly controls the pH value of the ammonium nitrate aqueous solution to meet the use requirements and ensure its safety during use.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

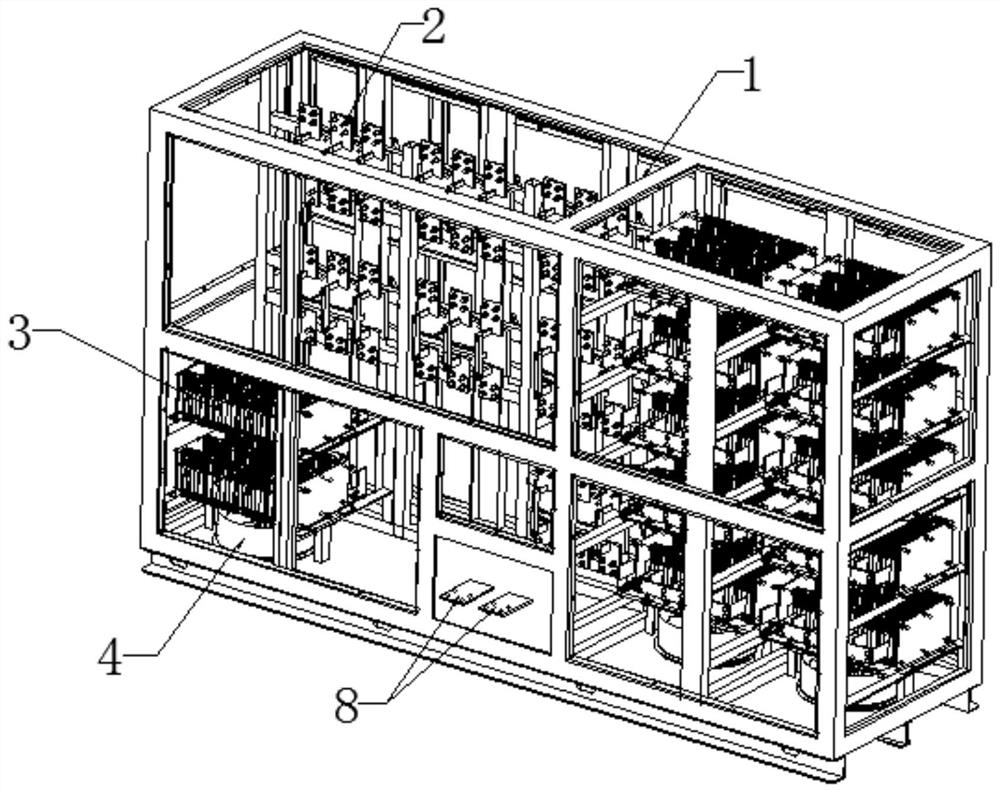

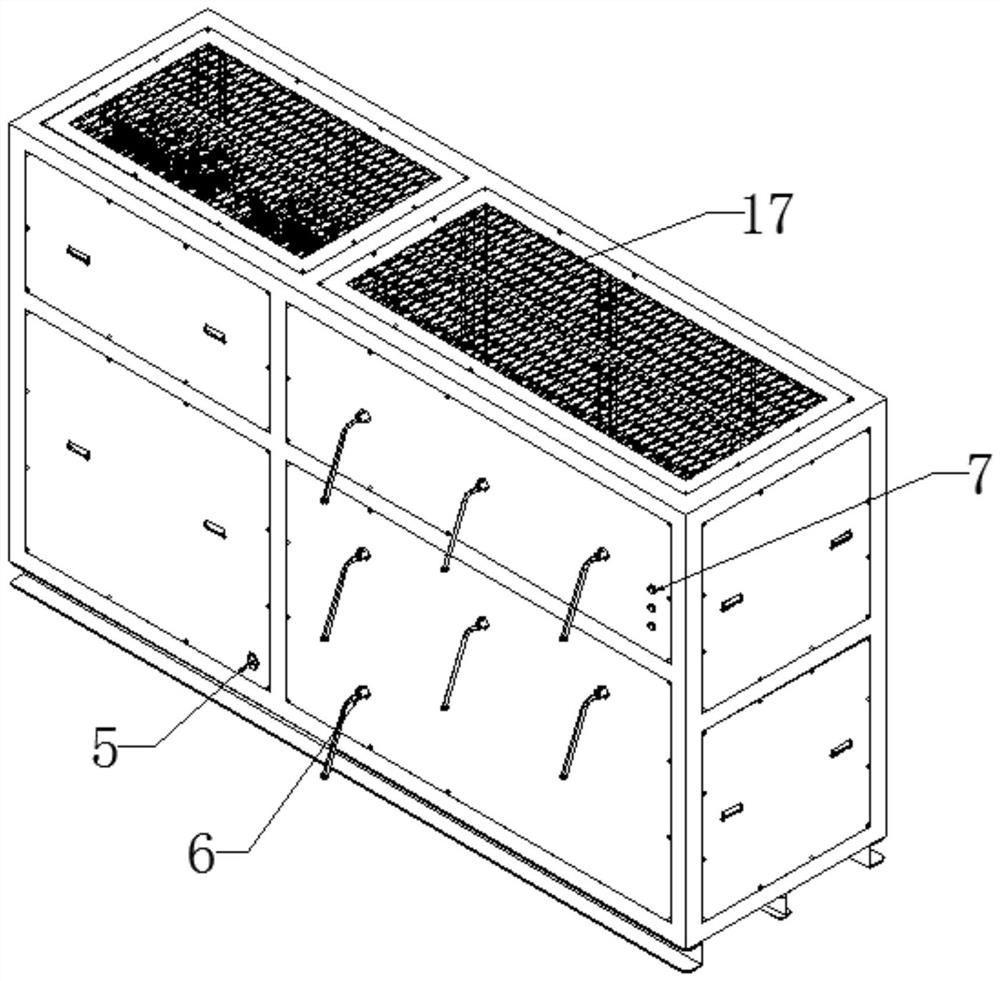

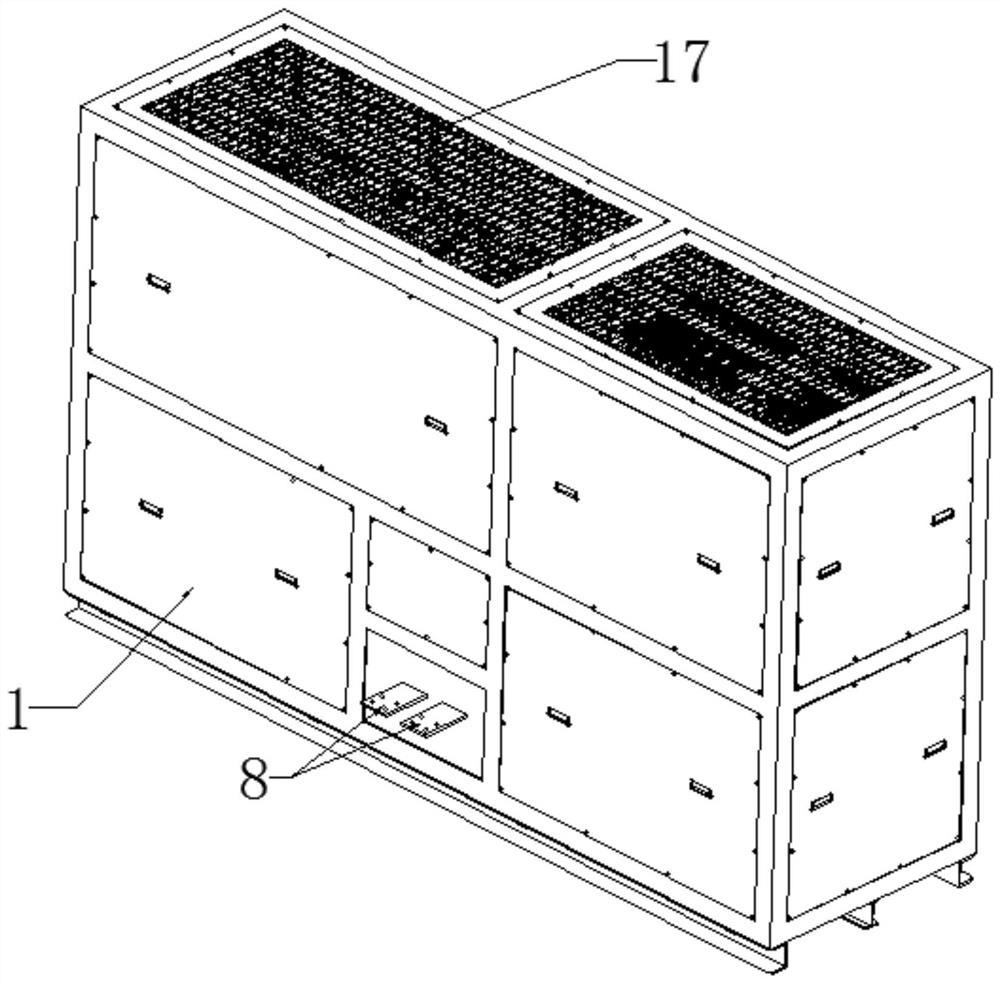

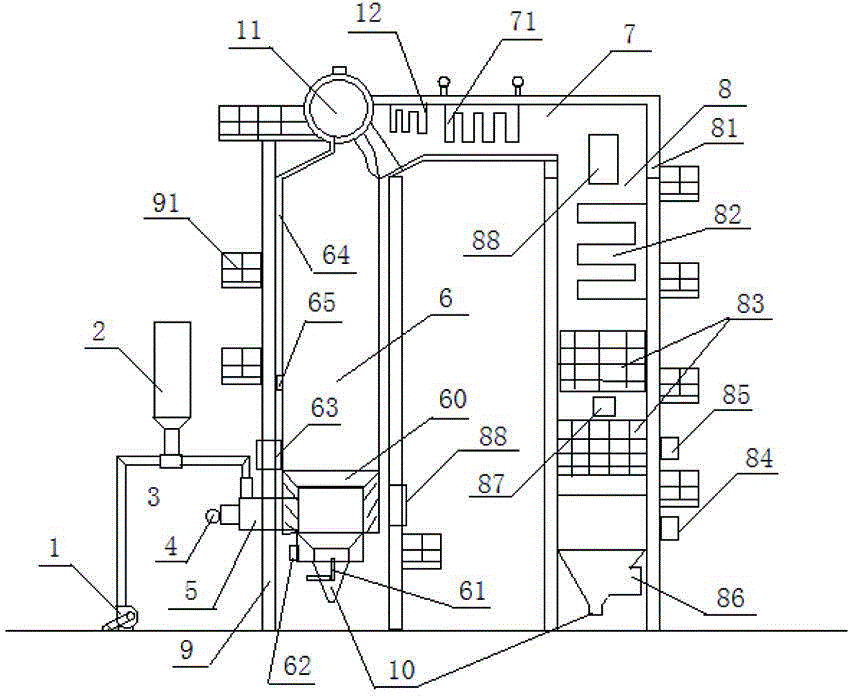

High-power high-stability large-current short-circuit test load cabinet for new energy power battery

PendingCN111766536AEasy to useEasy load adjustmentShort-circuit testingModifications by conduction heat transferPower batteryHigh current

The invention discloses a high-power high-stability large-current short-circuit test load cabinet for a new energy power battery. The high-power high-stability large-current short-circuit test load cabinet comprises a cabinet body, knife switches and integrated resistors, wherein the integrated resistors and knife switches are installed in the cabinet body, the integrated resistors are connected with the knife switches in series, a fan is correspondingly arranged below each vertical column of integrated resistors, the fans are installed at the bottom end of the cabinet body, and a heat dissipation screen plate is further installed at the top end of the cabinet body. According to the high-current test load cabinet, the power-on number of the integrated resistors in the cabinet body is controlled through the knife switches, the resistance of the load cabinet is changed, the load is convenient to adjust, and the high-current test load cabinet is suitable for high-current short-circuit test of high-power and high-stability new energy battery; and the integrated resistors have a good insulation effect and a good heat conduction effect, the fans are adopted to blow air to the integratedresistors in each vertical column, and heat emitted by the integrated resistors flows along with the air from bottom to top and is finally led out from the heat dissipation net plate at the top end ofthe cabinet body, so the efficient and rapid heat dissipation effect is achieved, and normal operation of the load cabinet is guaranteed.

Owner:深圳市正阳兴电子科技有限公司

Efficient steam boiler for gasification and combined combustion of pulverized coal

ActiveCN102818247BImprove burnout rateAccelerated settlementEnergy inputSteam boilersAir preheaterCombustion chamber

The invention discloses an efficient steam boiler for gasification and combined combustion of pulverized coal, comprising a blast blower, a pulverized coal bunker, a pulverized coal transmission pipe, a combustion chamber, a gasification chamber, a hearth, a horizontal flue, a steam superheater, a tail shaft and a boiler support, wherein the blast blower is connected with the pulverized coal bunker, and connected with the gasification chamber through the pulverized coal transmission pipe; a combustor is connected with the gasification chamber; the gasification chamber, the hearth, the horizontal flue and the tail shaft are connected in order, and arranged on the boiler support to form an inversed U shape; a non-combustion zone is arranged above the joint of the hearth and the gasification chamber; the hearth is provided with a jet flow air inlet and a secondary air inlet at the bottom; the outlet of the non-combustion zone is provided with a tertiary air inlet; the steam superheater is arranged in the horizontal flue; and the tail shaft is internally provided with a coal economizer and an air preheater. The efficient steam boiler for gasification and combined combustion of pulverized coal disclosed by the invention saves space, reduces dust emission, realizes gasified transmission, and stabilizes combustion; and the burn-off rate of the pulverized coal is above 99%, and the heat efficiency is above 93%.

Owner:青岛青义锅炉有限公司

Ball screw servo loading test device based on hydraulic servo system

InactiveCN104931253BEasy load adjustmentRealize working condition simulationMachine gearing/transmission testingServo actuatorBall screw

The invention discloses a ball screw servo loading test device based on a hydraulic servo system. The whole device has a vertical structure. A landing base is fixed on a pedestal or the ground, and a bottom plate is fixed on the landing base. Four supporting steel pipes are vertically fixed in the four corners of the bottom plate. An installing base is fixed at the upper ends of the four supporting steel pipes. A motor and a rotating speed torque sensor are installed on two of the supporting steel pipes. A rotating speed torque sensor shaft is respectively connected with a motor and a ball screw shaft. The nut of a ball screw is fixedly connected with a nut sleeve. The nut sleeve is installed in a rotation-limiting supporting base. The nut sleeve is connected with an electro-hydraulic servo actuator via an actuator connection plate. Active loading can be performed on the ball screw so that load adjustment is convenient, simulation of the working conditions of varied loads can be realized, the loads can be displayed and controlled in real time, and performance testing of the ball screw can also be performed.

Owner:NANJING UNIV OF SCI & TECH

A quality control system for storage tank ammonium nitrate aqueous solution

The invention provides a quality control system for a storage tank ammonium nitrate aqueous solution, comprising a storage tank, the upper part of the storage tank is provided with a filter, and the filter communicates with the top of the storage tank through a pipeline; the inside of the storage tank is respectively equipped with Horizontally arranged air distributor and heating pipe, the air distributor is connected with the air compressor outside the storage tank through the first pipeline; the outlet end at the bottom of the storage tank is connected with a circulation pump, and the circulation delivery pump The outlet end communicates with the upper end of the storage tank through the second pipeline; the top end of the storage tank is connected with an acid-base tank for adjusting the pH value. This control system controls the concentration, PH value, combustion residue, and solution temperature indicators of the ammonium nitrate aqueous solution, so that it can fully meet the standard requirements or customer needs, and ensure its safe use.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

Data center machine room air conditioner

InactiveCN110285518AAvoid wastingReduce energy consumptionMechanical apparatusLighting and heating apparatusData centerModular design

The invention discloses a data center machine room air conditioner. The data center machine room air conditioner comprises multiple air conditioner modules; the air conditioner modules comprise air conditioner modules with heat recovery devices, and air conditioner modules without the heat recovery devices; the air conditioner modules without the heat recovery devices comprise first inner units and first outer units; the first inner units comprise first evaporators and first compressors; the first outer units comprise first condensation modules; the air conditioner modules with the heat recovery devices comprise second inner units and second outer units; the second inner units comprise second evaporators and second compressors; the second outer units comprise second condensation modules and air heaters; the first evaporators are connected with the first condensation modules through the first compressors; the first condensation modules are connected with the first evaporators; the second evaporators are connected with the second condensation modules through the second compressors; and the second condensation modules are connected with the second evaporators and the air heaters. The data center machine room air conditioner adopts modular design to achieve flexible adjustment and convenient maintenance, and adopts a heat recovery technology in winter to effectively use the heat energy.

Owner:陈红杰

A method for deoxygenating and finely desulfurizing coke oven gas

ActiveCN108977233BRealize deep purificationImprove operational reliabilityDispersed particle separationGas contaminants removalUnsaturated hydrocarbonPhysical chemistry

The invention discloses a method for deoxidizing and finely desulfurizing a coke oven gas. The method comprises the following steps: (S1) heat exchanging and temperature rising; (S2) prehydrogenationconversion and first-stage hydrogenation conversion; (S3) first-stage desulfurization; (S4) secondary heat exchanging and temperature rising; (S5) second-stage hydrogenation conversion; (S6) second-stage fine desulfurization. According to the method for deoxidizing and finely desulfurizing the coke oven gas, disclosed by the invention, a two-stage coke oven gas hydrogenation deoxidization and finedesulfurization technology is adopted, most of organic sulfur in the coke oven gas can be converted into H2S by utilizing a first-stage hydrogenation deoxidization and desulfurization section, most of oxygen can be removed through hydrogenation, most of unsaturated hydrocarbon can be saturated through hydrogenation, and meanwhile, other impurities can be treated; the treated coke oven gas entersa second-stage hydrogenation deoxidization and fine desulfurization section, impurities of residual organic sulfur, unsaturated hydrocarbon, trace oxygen and the like can be subjected to secondary deep hydrogenation conversion and treatment, and deep purification of the coke oven gas can be realized.

Owner:太原智领科技有限公司

Multipath magnetic circuit unit lamellar permanent-magnet linear oscillating motor

InactiveCN101789661BSimple preparation processEase of mass productionMagnetic circuit rotating partsSynchronous machinesAlternating currentH shaped

The invention relates to a multipath magnetic circuit unit lamellar permanent-magnet linear oscillating motor comprising a stator part and a rotor part; the stator part comprises a tubular cavity and magnetic circuit units; the tubular cavity has outer surfaces in a regular polyhedron; the magnetic circuit units are arranged on the outer surfaces; each magnetic circuit unit comprises a middle magnetic conductor and two magnetic conductors, wherein the longitudinal section of the middle magnetic conductor is in an H shape, a column of the middle magnetic conductor is wound by a coil, the two magnetic conductors are arranged at both sides of the middle magnetic conductor, and a strip-shaped air gap is arranged between the middle magnetic conductor and each of the magnetic conductors; the rotor part comprises a plurality of lamellar permanent magnets and symmetrical type magnetic circuits, wherein the plurality of lamellar permanent magnets are vertically arranged on connecting pieces ina radial shape, are inserted into a rectangular hole positioned in the connecting piece positioned at one end of the tubular cavity and extend into a rectangular hole positioned in the connecting piece positioned at the other end of the tubular cavity; each magnetic circuit unit is positioned among the lamellar permanent magnets; the symmetrical type magnetic circuits are formed by symmetrically magnetizing the middle magnetic conductor and the magnetic conductors along the length direction of the middle magnetic conductor; the coil generates a magnetic field by being electrified with alternating current and forms a magnetic field with alternate positive and negative directions in the strip-shaped air gaps through the symmetrical type magnetic circuits; and the rotor does reciprocating oscillation motion along the length directions of the strip-shaped air gaps in the strip-shaped air gaps under the action of the magnetic field.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com